Autonomous solid fuel boilers for heating a private house run on wood, coal, coke, peat, pellets, briquettes, granules, and utilize woodworking and agricultural waste. The eco-friendly heat generator does not depend on centralized gas and electricity supply. Combined models improve the quality of the main or reserve source, increase efficiency, and reduce the cost of the heating system.

Content [Hide]

Solid fuel boilers for heating a private house: design features

Material for the manufacture of units: cast iron or high-strength boiler steel. Material properties affect the service life and thermal inertia of the structure. Steel boilers have a high resistance to deformation under pressure and temperature changes. Cast iron is resistant to corrosion.

The advantages of steel boilers: reasonable price, aesthetic appearance, convenient loading. Advantages of cast iron equipment: simplicity in operation (they do not require special preparation of boiler water), durability, the ability to give off heat for a long time.

Cast iron units are chosen for houses with permanent residence of people. For summer cottages and country houses with periodic residence, steel boilers are used.

The complete set of heat generators is subdivided into single or double-circuit design. One circuit provides a solid fuel boiler for heating a private house. Two independent rings allow heating the room and supplying hot water.

The energy dependence is due to the equipment of the unit with a forced air supply system for combustion or automated fuel loading.

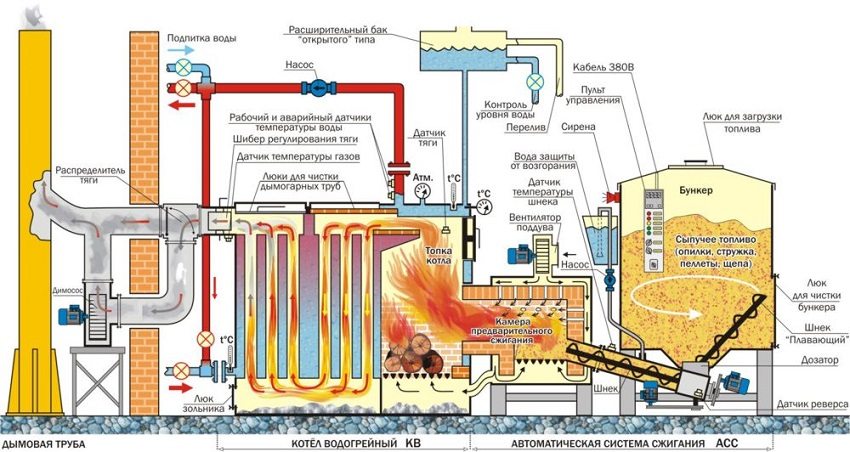

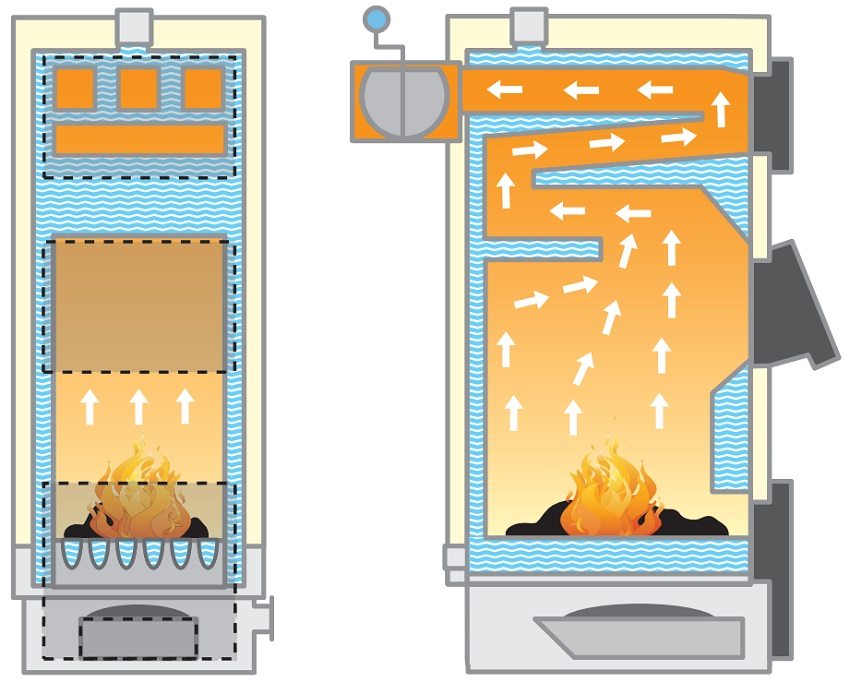

By the time of fuel combustion, traditional and pyrolysis heating boilers are distinguished. Gas generators provide long-term decomposition of fuel with the release of heat, which occurs when there is a lack of oxygen. Some models provide for loading solid fuel boilers for long burning once a week.

Pyrolysis boilers are in demand by the consumer due to energy independence, economical fuel consumption, environmental friendliness and high efficiency.

Chimney rules for solid fuel boilers

Additional requirements for the organization of the chimney are indicated by the boiler manufacturer in the technical documentation. Mandatory adherence to the recommendations is necessary to maintain a stable combustion process, safe and efficient operation of the unit.

Related article:

Solid fuel boilers for long burning with a water circuit for home. INides, device and principle of operation of solid fuel boilers. Pyrolysis boilers. Boiler selection criteria.

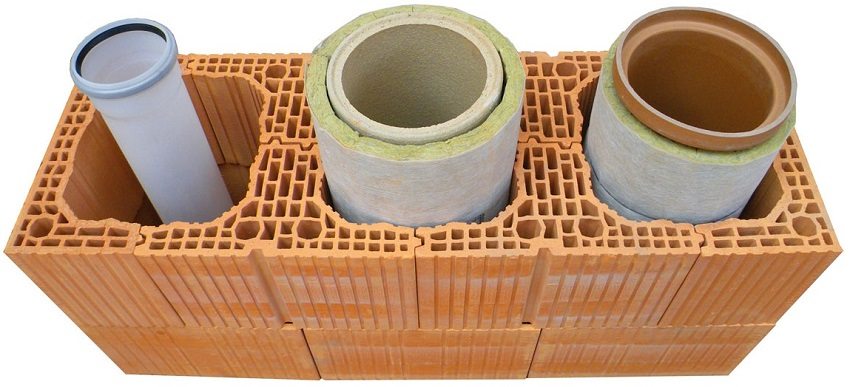

Coal fired boilers are equipped mainly with ceramic chimneys that can withstand temperatures up to 1200 ℃. The flue gases leave no deposits on the smooth ceramic surface. The stable structure of the material is not subject to corrosion and is not afraid of condensation. Elements of an air duct, a layer of insulation, expanded clay concrete shell are used for the installation of internal and external sections of the chimney.

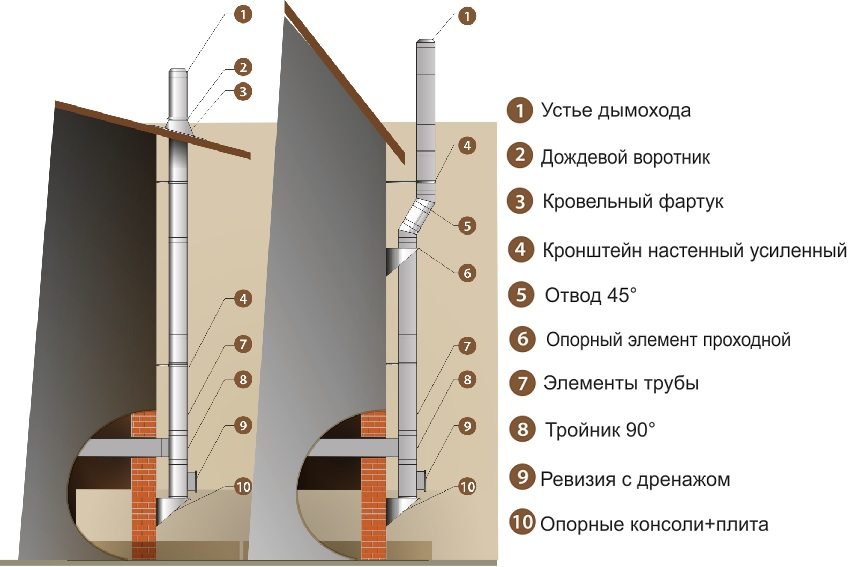

Metal chimneys are made of heat-resistant steel, resistant to corrosion, which can withstand a temperature of 800 ℃. The design of the steel chimney is a sandwich pipe: a layer of thermal insulation is located between the outer and inner metal shells. Steel chimneys are compatible with all types of solid fuel boilers. An obligatory element of a steel chimney is a linear deformation compensator. The unit is necessary to preserve the integrity and tightness of the pipe bushing through the roof.

Refractory bricks, traditional for hearths, fireplaces, heating stoves, are rarely used for laying out chimneys. Brick laying of a chimney requires skills and experience in the production of furnace work.

Requirements for the arrangement of chimneys for solid fuel boilers:

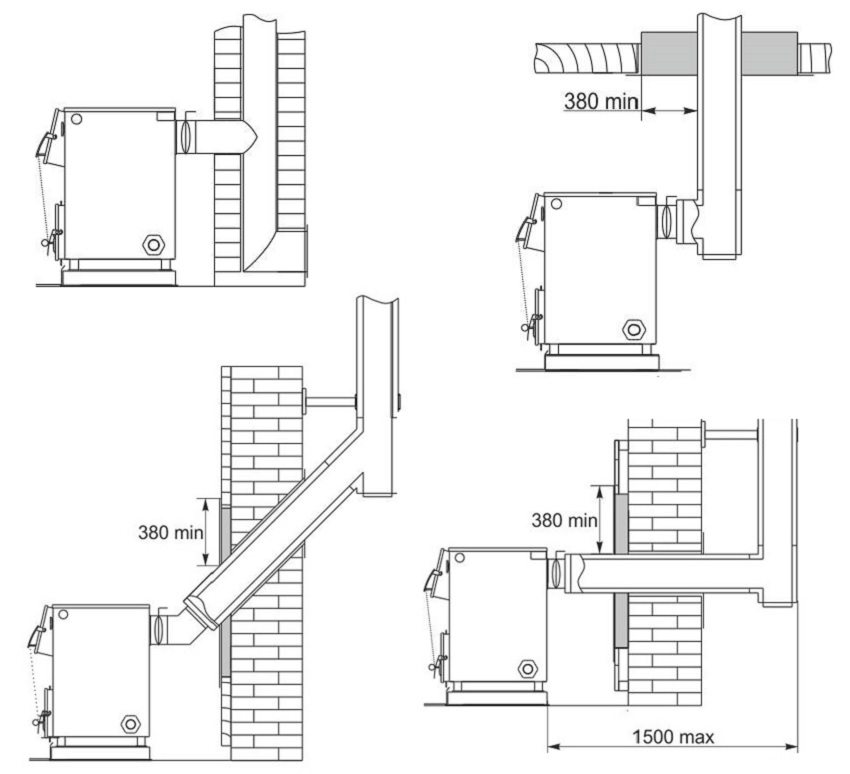

- the cross-section of the chimney must correspond to the size of the boiler branch pipe for exhausting gases;

- the height, diameter, length of the booster section of the chimney is indicated in the technical documentation of the boiler;

- the verticality of the structure is observed regardless of the location of the chimney (the permissible length of the sloped sections does not exceed 1 meter);

- double-walled (insulated) chimneys made of metal pipes are used in cold rooms and outdoors (the design prevents the cooling of combustion products, a decrease in draft and the appearance of condensation);

- on the turning sections arrange hatches for cleaning the chimney;

- observe fire-prevention distances between the chimney and flammable structures;

- the chimney head is equipped with a deflector and a spark arrestor.

Important! A T-piece installed below the connection between the boiler and the chimney prevents condensate from entering the combustion chamber.

Wiring diagrams for a solid fuel heating boiler

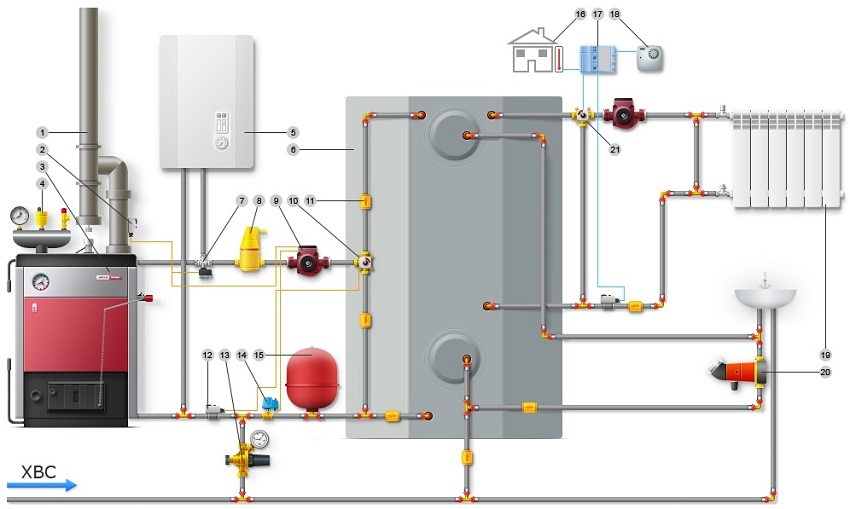

Direct connection of the boiler to the heating circuit is dangerous due to the formation of temperature differences in the heat exchanger. When the “dew point” state is reached, condensate forms inside the combustion chamber. The aggressive environment promotes oxidative reactions, the formation of deposits and the destruction of the inner surfaces of the generator.

Important! The inertia of the solid fuel combustion process is a feature that must be taken into account when connecting the boiler to the piping. Unbalanced and disturbed circulation can lead to boiling of the boiler water and damage to the heat generator.

Ways to optimize the operation of a solid fuel unit:

- heat storage tank between the boiler and the consumer circuit;

- hydraulic separator of the circuits (boiler and secondary);

- safety group with an adjustable relief valve (near or on the boiler);

- expansion tank (open or diaphragm);

- air vents to remove air from the system.

Important! The boiler is connected and piped only with metal pipes. The ideal option is a heating boiler piping scheme according to the project, which was developed by heating specialists.

Solid fuel boiler piping scheme: 1 - chimney; 2- overhead thermostat; 3 - solid fuel boiler; 4 - boiler safety group; 5 - electric or gas boiler; 6 - heat accumulator (buffer tank); 7 - three-way valve with an electric drive; 8 - air separator; 9 - circulation pump; 10 - three-way mixing valve; 11 - check valve; 12 - patch sensor; 13 - make-up valve; 14 - protection against dry running; 15 - expansion tank; 16 - outdoor temperature sensor; 17 - weather-dependent automation; 18 - room regulator; 19 - heating radiator; 20 - circulation pump; 21 - three-way mixing valve

Russian-made solid fuel boiler brands

Analysis of technical characteristics will help to get a general idea of solid fuel boilers for long burning. Consumer reviews on independent forums provide an objective assessment of domestic developments.

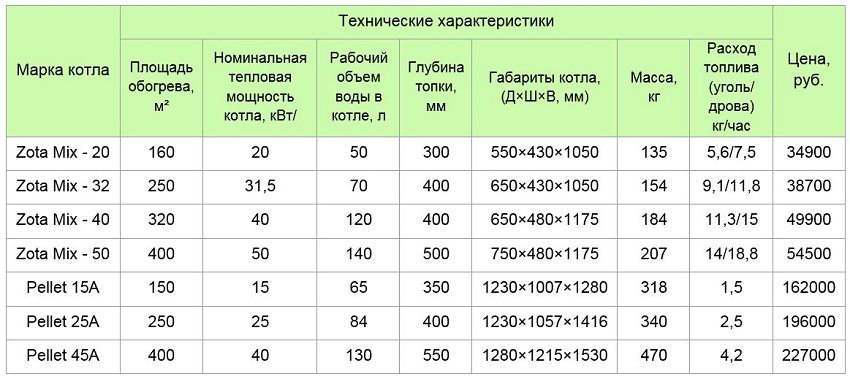

Table 1. Solid fuel boilers Zota Mix and Pellet produced by the heating equipment and automation plant (Krasnoyarsk):

Table 1. Solid fuel boilers Zota Mix and Pellet produced by the heating equipment and automation plant (Krasnoyarsk)

Advantages:

- Efficiency of boilers of the Zota Mix model range - 80%, Pellet - 90%;

- Zota Mix combined steel solid fuel boilers operate on any type of fuel (liquefied or natural gas, electricity, liquid fuel);

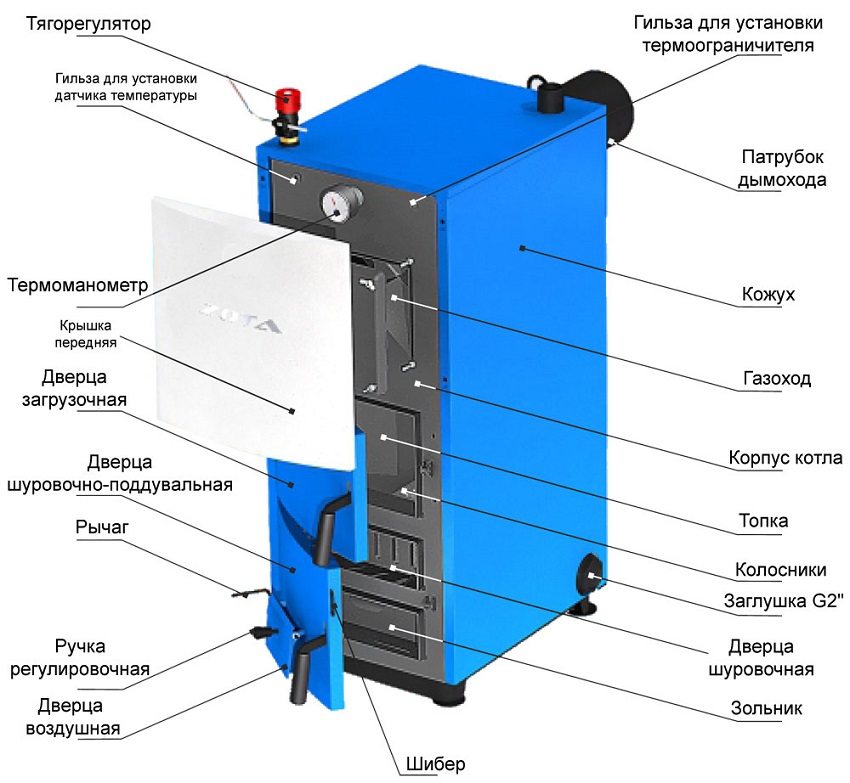

- the combustion chamber and ash box are located inside the water jacket;

- adjustable chimney damper, mechanical traction regulator and air suction by an ejector, which is installed in the furnace door, ensure complete fuel combustion with minimal draft;

- the outer surface of the body is covered with an anti-corrosion polymer compound;

- removable door behind the front panel provides access for cleaning the flue;

- the possibility of repair.

Disadvantages:

- you need a supply of fuel and a place to store it;

- costs of delivery, unloading and storage of firewood, coal, briquettes;

- decrease in the performance of Zota Mix boilers when using low-quality fuel (brown coal by 10 ÷ 20%, raw firewood by 60 ÷ 70%);

- for Zota Mix - manual loading of fuel, cleaning of the ash pan, furnace walls, gas ducts and flue pipe;

- obligatory preparation of boiler water (hardness up to 2 mg-eq / l);

- installation in a separate room;

- for boilers of the Zota Mix line, it is necessary to install a heat accumulator, a smoke exhauster, a boiler.

Table 2. Combined solid fuel apparatus with a water circuit (AKTV). Manufacturer Sibteploenergomash LLC (Novosibirsk):

Table 2. Combined solid fuel apparatus with a water circuit (AKTV). Manufacturer Sibteploenergomash LLC (Novosibirsk)

Advantages:

- budget version of solid fuel boilers with a water circuit for the house (price 11,000 ÷ 25,000 rubles);

- compact size;

- a water heat exchanger covers the firebox from all sides (except for the front);

- pull-out ash drawer;

- mounting socket for draft regulator;

- the ability to connect to a chimney of any configuration;

- steel heat exchanger allows simplified connection to heating piping (without mixing);

- the design is adapted to work on gas and electricity.

Disadvantages:

- outdated design, low quality primitive automation;

- the technical characteristics declared by the manufacturer (power, heated area and efficiency), according to consumer reviews, do not correspond to the actual indicators.

Table 3. Solid fuel pyrolysis boilers Bourgeois & K from NPO TES LLC (Kostroma):

Advantages:

- provides stable combustion of fuel of any grade and degree of moisture;

- efficient operation of the boiler from one tab for 8 hours;

- economical fuel consumption;

- generator compatibility with natural or forced circulation systems;

- environmentally friendly unit, the fuel goes through a complete combustion cycle without generating harmful emissions into the atmosphere;

- the design of the firebox provides an exit to an effective operating mode in 40 minutes.

Disadvantages:

- complex installation: the connection must be made by employees of specialized enterprises licensed for this type of activity (otherwise the warranty from the manufacturer does not apply to the unit);

- manual fuel filling and cleaning of the combustion chamber;

- great weight.

Installation and operation of solid fuel boilers must be carried out in accordance with fire safety rules

For heating a country cottage, garage or greenhouses it is possible to manufacture solid fuel boilers for long burning with your own hands. Videos with materials on this topic can be found on the Internet. But remember that the main condition for using heating equipment is fire safety. And only a certified manufacturer can guarantee the fulfillment of this condition under proper operating and installation conditions.