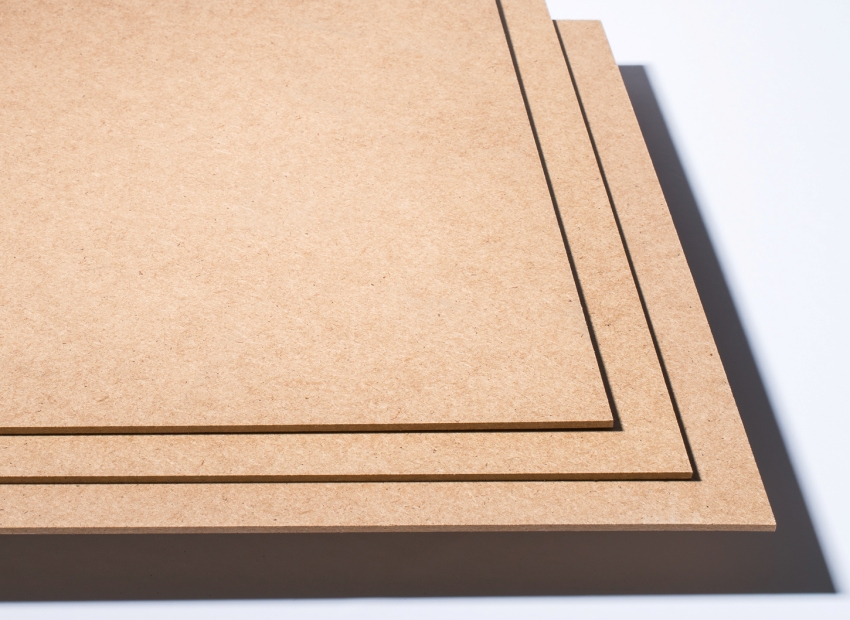

Hardboard, or fiberboard - one of the most popular modern building materials. Fiberboard is used for finishing the floor and walls, installing interior partitions, for insulating the roof. It is an excellent material for making furniture and doors. When buying a sheet, the density, size, production time, transportation and storage conditions are evaluated. The main criteria for choosing the right fiberboard are: sheet thickness and dimensions, material price. This will be discussed in this article.

Content [Hide]

- 1 Fiberboard production

- 2 Fiberboard: sheet thickness and dimensions, material price

- 2.1 Standard sizes of fiberboard sheet

- 2.2 Fibreboard applications depending on the thickness of the product

- 2.3 Fiberboard price per product sheet

- 2.4 Thickness and dimensions of fiberboard sheet: prices and product photos

- 2.5 Standard thickness and dimensions of fiberboard sheet. Product price: what affects it?

- 3 Where can you buy quality building material?

Fiberboard production

The increase in the cost of resources and concern for the ecological state of the environment forces many manufacturers to invent new building materials and introduce technologies that can significantly save raw materials without much damage to the quality of the final product. A striking indicator of such changes is the sphere of furniture production, where various synthetic materials have replaced natural solid wood.

The first imported furniture, which was imported into our country in the second half of the twentieth century, with its aesthetic and durable design, showed that wood waste can be used for manufacturing. Further development of the fiberboard production technology made it possible to bring the appearance of the material closer to natural wood, ennobling the plates with a special film, similar in texture to wood. The production of laminated fiberboard has grown exponentially. Today this material can be purchased at a very affordable price. Sizes of a sheet of laminated fiberboard are different and will satisfy any, even the most non-standard, consumer request.

Fiberboard: sheet thickness and dimensions, material price

The possibility of obtaining the required working area, the minimum amount of waste and the final strength of the finished product depend on the correct determination of the required dimensions of the building material.

When performing finishing activities, preference is given to whole slabs. To determine the number of pieces, the total area of the working area is calculated taking into account the cutting. In some cases, it is possible to purchase individual blanks that can be bought in woodworking shops. The total cost of such residues includes the cost of cutting them.

Detailed measurements of the walls, floor and ceiling are taken before cutting out the sheets for finishing works and thermal insulation.Then, based on standard boards of different sizes, options for their cutting schemes are drawn up, and the number of residues in each case is compared. The most optimal option is selected, at which the minimum amount of trimmings is achieved.

Useful advice! Knowing the required dimensions of fiberboard, you can decide in advance on the method of transportation and a convenient place for storing the plates.

Standard sizes of fiberboard sheet

Fiberboard is considered an improved and more advanced analogue of particleboard. Orgalin has an increased value of strength and density of the material. It was possible to improve these parameters due to a more thorough grinding of the raw material with its subsequent pressing under the influence of high pressure.

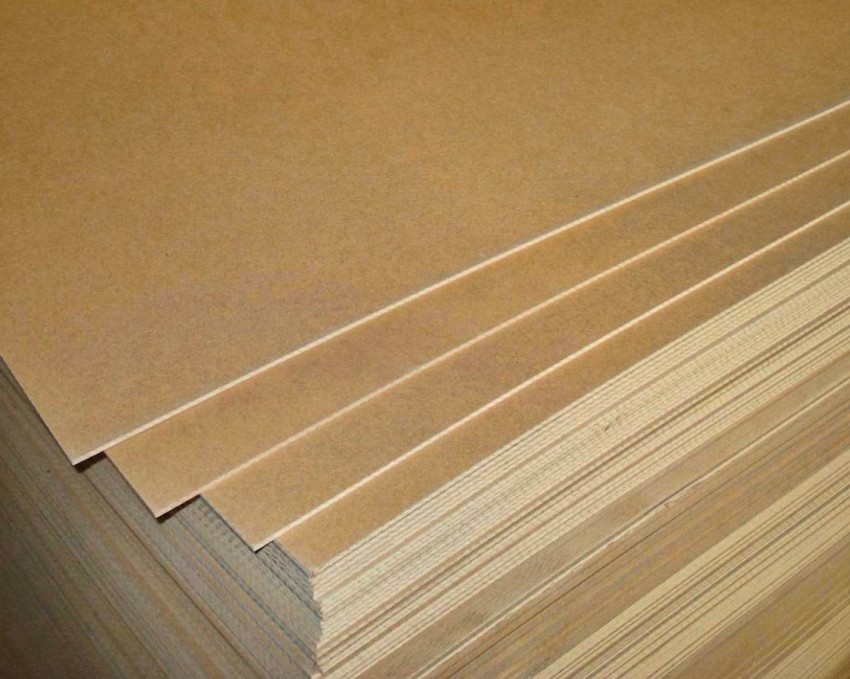

The thickness of the fiberboard varies depending on the density of the material and is 3.5-25mm. Each type of fiberboard has its own size range. Soft and medium density fiberboard is the thickest. The thickness of these slabs is 8, 12, 16 and 25 mm. Semi-hard fiberboard has a thickness of 6, 8 and 12 mm. The thinnest are hard and superhard fiberboards with a thickness of 3.2 mm, 4.5 mm and 6 mm.

The dimensions of fiberboard sheets of different hardness are almost the same. They are determined based on the specific equipment that the manufacturer uses. The length of the slabs is 1220-3660 mm, the width is 1200-2140 mm.

Standard dimensions of fiberboard sheet according to GOST 4598-86:

- soft fiberboard: length - 1220, 1600, 1800, 2500, 2700 and 3000; width - 1220 mm;

- semi-solid, solid, superhard fiberboard: lengths - 1220, 1700, 1800, 2050, 2500, 2745, 3050, 3350 and 3660; width - 610, 1220, 1525, 1830 and 2410mm.

Useful advice! The slab can be made to order with dimensions that differ from the standard. But the maximum dimensions for soft boards are 5.5 m, for hard fiberboard - 6.1 m.

Fibreboard applications depending on the thickness of the product

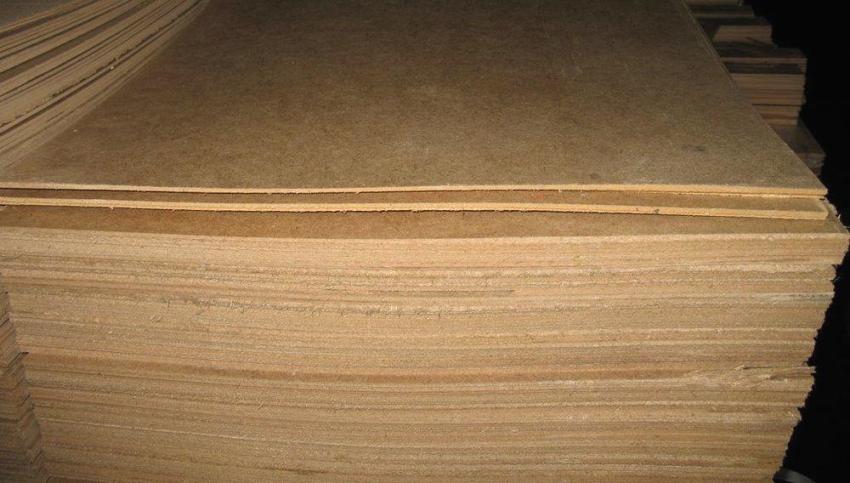

The thickness of the fiberboard sheet and its strength are inversely related. Accordingly, before starting construction work, it is necessary to determine the type of fiberboard for its purpose.

For heat-insulating cladding of walls, ceilings and ceilings, porous soft fiberboard with a thickness of 8-12 mm is used, which resembles felt. These boards are also good sound insulators.

Semi-solid type of slabs that resemble thick cardboard up to 12 mm thick can be used for the manufacture of furniture, as the back walls of cabinets and drawers. This material is used as a substrate for future flooring.

Solid slabs up to 6 mm thick are an excellent cladding material for walls and ceilings. I use it for the installation of interior partitions and for the manufacture of door panels.

Superhard boards with a thickness of 6 mm are used for cladding floors, doors and furniture. Unlike hard fiberboard, they are impregnated with resins, and a special PVC-based film is applied to the surface.

To correctly determine the size of the fiberboard sheet, the width and length of which are different, it is necessary to measure the dimensions of the working surface. By multiplying the linear indicators, the total area of each individual site is obtained. Adding them together, we get the total number of sheets for purchase. Further, all layouts of plots are located in a rectilinear plane, and a rectangular contour is drawn up, which covers all images. After that, from the available standard sizes of fiberboard, the most acceptable ones are selected, which will provide the minimum material residue.

Fiberboard price per product sheet

The cost of fiberboard depends on the overall dimensions, type of material, manufacturer, and the number of intermediaries. Soft fiberboard, regardless of size, has the lowest cost. Imported products will cost significantly more, which does not always lead to good quality. For example, hard fiberboard with a size of 2140x1220 mm and a thickness of 3.2 mm will cost 150 rubles.from a Russian manufacturer, and 210 rubles. from imported.

Untreated fiberboard with a size of 2745x1700 mm with a thickness of 3.2 mm will cost around 460 rubles, and the price of laminated fiberboard per sheet will be about 1026 rubles.

In order to consciously make a choice of a Russian-made product, it is necessary to compare the pricing policy of one type of product of the same thickness.

Comparison of prices for solid fiberboard with dimensions of 2140x1220 mm and thickness of 3.2 mm:

| Manufacturer | Price, rub / piece | Price, rub / m² |

| Vendor | 132 | 50,77 |

| Stroyway | 126 | 48,46 |

| Marina | 179 | 68,81 |

An important criterion is the actual location of the manufacturer. The closer it is, the less will be the transport component of the price. You can save a lot when buying a lot in bulk.

Thickness and dimensions of fiberboard sheet: prices and product photos

The final price of the product depends on the type, thickness, dimensions of the sheet, the front side is refined or untreated.

Prices for material from the catalog of OOO Stroitekhmontazh:

| Material name | Plate size, mm | Thickness, mm | price, rub. |

| Fiberboard white | 1220x2440 | 6 | 430 |

| Wood grain fiberboard | 1035 | ||

| Laminated fiberboard | 1046 |

Standard thickness and dimensions of fiberboard sheet. Product price: what affects it?

All well-known manufacturers of fiberboard produce products of a certain format with standard sizes. Why, then, the pricing policy of different manufacturers is significantly different? After all, the method of manufacturing fiberboard has remained unchanged for many years, and the range of types and colors is similar.

The final cost is influenced, first of all, by the big name of a well-known manufacturer. Then its location is taken into account. And this is directly related to the transport costs that the manufacturer spends in the manufacture of the material.

The next criterion that affects the cost of the final product, the size and thickness of the product. Depending on the dimensions of the material, a different amount of raw materials and chemical impurities is consumed.

Grade also affects the cost of the material. Fiber boards are of two grades: grade I has no visible damage, for grade II minor dents and scratches on the front side of the product are allowed.

The next parameter is a kind of fiberboard. The composition of the raw material, its quantity, processing method and the presence of impurities play an important role here.

The presence of a protective layer and decorative coating adds an additional margin to the cost of production. Here, the manufacturer spends on the costs associated with the technology of applying the necessary texture to the board, therefore the price of a laminated fiberboard sheet, the dimensions and thickness of which are clearly standardized, will be much higher than that of a simple unpolished fiberboard of the same dimensions.

The table below shows the estimated cost of fiberboard. Prices for laminated, painted and non-refined sheets are indicated in rubles per sq. meter:

| Thickness, mm | Untreated coating | Painted coating | Laminated coating | |||

| Solid | Soft | Solid | Soft | Solid | Soft | |

| 3,2 | 57-60 | 40 | 90-95 | 85 | 185-193 | 70 |

| 6 | 130-140 | 89 | 120 | 107-115 | 200-216 | 100-115 |

| 12 | — | 95 | — | 136 | — | 140 |

| 16 | — | 155 | — | 160 | — | 160-190 |

Useful advice! Some manufacturers sell substandard sheets that do not meet the requirements of GOST in terms of their dimensions or external condition (damaged edges). These defects do not have a significant negative impact on the quality of the panels, but will help to save on material costs.

The difference in pricing policy for a fiberboard sheet is quite significant, therefore, if there is too much of a whole sheet to perform a small amount of work, you can ask repair and construction stores about the availability of fiberboard scraps of different lengths, which are sold at a reduced price.

Where can you buy quality building material?

Today in the country there are a huge number of retail outlets where you can buy building materials for any request. Each store tries to expand its assortment, according to the requirements of the consumer and the emergence of new products on the market.

Repair and construction work is a very responsible and painstaking undertaking. It is necessary to approach the choice of the necessary materials with all responsibility and care. Having studied in detail the pricing policy of construction stores, you can choose the most acceptable option for yourself.

Useful advice! It is convenient to purchase the necessary materials in large hardware stores, where there is a wide range of products, and specially trained consultants will help you choose exactly what you need.

One of such large hypermarkets is the Epicenter store, which offers a wide range of goods covering all spheres of human life. The products are categorized and clearly displayed in sales areas. Additionally, you can order goods that are missing at this time.

In the Epicenter network, the price for a fiberboard sheet is optimal, and the availability of positions from different manufacturers makes it possible to choose the desired product in one place, which will save time.

To purchase construction goods, you can use the services of online stores. Many such structures work directly with manufacturing plants, which determines the cost of products, which is an order of magnitude lower than that of competitors. You can place an order without leaving your home at any convenient time. And the fast delivery service will allow you to receive the goods at the specified place in the shortest possible time.

The modern range of fibreboards is very diverse. Everyone can choose a worthy option for themselves, based on their scope of fiberboard application and their own financial capacity. If you approach the choice of this building material correctly, having previously studied the pricing policy for your region, you can get a good product for a very reasonable fee.

Related article:

Fiberboard: what is it? How to choose the right building material

The history of the origin of the material. The main types of fiberboard and selection criteria for fiberboard. Areas of use. Advantages and disadvantages of the material.

But do not forget that the better the raw materials, additional components and the more reliable the level of pressing, the better the quality of the final product and, accordingly, the higher its cost.