Porcelain stoneware is a stone-porcelain tile that is distinguished by high performance and is very popular in construction. Frost-resistant porcelain stoneware for the street is used for facing facades, making steps and for other purposes. The selection and installation of material requires knowledge of its varieties and their differences from each other, the nuances of working with them.

Facade decoration with such modern material as frost-resistant porcelain stoneware has many advantages

Content [Hide]

- 1 Types of porcelain stoneware

- 2 Characteristics and advantages of porcelain stoneware

- 3 How to choose the right porcelain stoneware

- 4 Subtleties of laying material

- 4.1 The choice of frost-resistant glue for porcelain stoneware for outdoor use, the nuances of use

- 4.2 Facing with porcelain stoneware with glue: recommendations

- 4.3 Facade finishing with frost-resistant porcelain stoneware

- 4.4 Components of a ventilated porcelain stoneware facade and its installation

- 4.5 Frost-resistant porcelain stoneware for outdoor use: installation of porcelain stoneware steps

- 4.6 Facing steps with porcelain stoneware

- 5 Features of waterjet cutting of porcelain stoneware and other processing methods

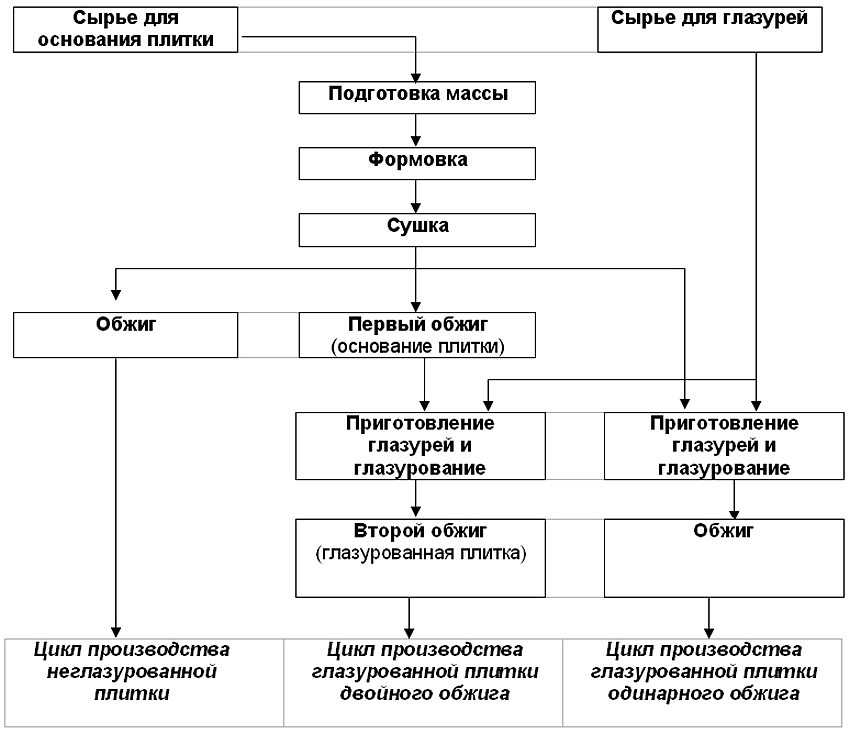

Types of porcelain stoneware

This material has appeared on the market relatively recently, but has already gained great popularity among buyers. The use of Italian and Spanish frost-resistant porcelain stoneware is considered a sign of good taste and well-being. The material itself appeared as an alternative to natural stone, but modern tile models can imitate various surface options. There are the following main types of porcelain stoneware:

- technical - durable and reliable, but not particularly attractive in appearance. Technical tiles are relatively inexpensive and are used for cladding industrial premises and technical areas;

An important criterion when choosing porcelain stoneware for the street is the degree of planned load on the surface faced with this material.

- matte - characterized by an unglazed surface. The use of matte porcelain stoneware for the street is advantageous in that this type of material has a high level of durability, but such a tile needs regular maintenance, since traces easily remain on its surface;

- polished - has a characteristic mirror shine, is most often used for facing facades and other vertical surfaces. It is not recommended to use polished tiles for facing floors or steps, as over time the coating wears off and the tiles become matte;

- glazed - the surface of this type of porcelain stoneware is covered with a special glaze, which gives it a unique shine.Such porcelain stoneware tiles for the street can be stylized for different materials, have different colors and patterns. It is better to use it for finishing walls and other surfaces that will not be subject to heavy loads;

- satin - granite, on the surface of which a layer of mineral salt is applied. After firing, such tiles boast a velvety surface structure. Used for decorative purposes;

- structured is another decorative variety that can look like products made from natural stone, wood, leather and other materials.

In the modern construction market, a wide selection of offers of porcelain stoneware tiles of various designs and characteristics

Each type of tile has its own advantages and disadvantages, and it is worth choosing depending on your needs and the characteristics of the use of the material.

Helpful advice! One of the main criteria for choosing porcelain stoneware for a stone for the street is the maximum load on the material. Therefore, first of all, you need to build on this parameter, and then take into account the other characteristics.

Characteristics and advantages of porcelain stoneware

One of the main advantages of porcelain stoneware tiles over other facing materials is its increased density and strength. It is significantly superior in performance to conventional ceramic tiles and has the following features:

- frost resistance - the ability to easily endure low temperatures is one of the main advantages of frost-resistant porcelain stoneware for outdoor use. You can buy such material for use at temperatures up to - 50 ° C, so it is beneficial to use it for use in open space. In addition, this material can withstand temperature extremes;

- resistance to wear - the tile resists scratches, chips and other mechanical damage well, which allows it to be used with equal efficiency for finishing steps, porches, floors in the house and other surfaces that are often subjected to high mechanical stress. The service life of anti-slip frost-resistant outdoor porcelain stoneware is approximately 7 years or more;

- low level of moisture absorption - porcelain stoneware tiles do not absorb moisture at all, so it can be safely used at any humidity;

- impact resistance - you can drop a heavy object onto a surface covered with porcelain stoneware without fear of damage to the coating. At the same time, the thicker the tile, the greater its resistance to impact, therefore, the thickness of porcelain stoneware for the porch on the street should be high enough.

All these advantages make porcelain stoneware an excellent option for use as a cladding material for a wide variety of surfaces. It is not afraid of frost and heat, it tolerates heavy loads and can serve you for many years without losing its attractive appearance.

How to choose the right porcelain stoneware

When choosing a material, you need to pay attention to a number of important points. One of the first is the tile manufacturer. The level of quality depends on the manufacturer, so Italian models should be preferred. They are more expensive than domestically produced porcelain stoneware, but they also have higher performance characteristics.

The second most important tile parameter is the presence of a non-slip surface. Buying outdoor non-slip porcelain stoneware will keep you safe as you can easily get hurt when using a slippery surface. High-quality tiles should be rough to reduce the risk of injury even when wet.In addition, tiles that are too smooth will often have to be sprinkled with sand and other anti-slip materials, which can quickly lead to a loss of its attractiveness.

The use of anti-slip frost-resistant porcelain stoneware for outdoor anti-slip is more profitable than the use of corrugated surfaces. The latter do not slip so much as smooth ones, but it is much more difficult to clean from dirt and quickly wear off, acquire an unattractive appearance. There are several varieties of non-slip frost-resistant porcelain stoneware in terms of wear resistance:

- PEI I, II - low wear resistance, it is recommended to use it for cladding vertical surfaces or floors that are not expected to be heavily loaded;

- PEI III - Medium durability, best used in residential areas with low traffic;

- PEI IV - good wear resistance, can be used in public buildings;

- PEI V is the maximum level of stability.

The choice of the appearance of anti-slip frost-resistant porcelain stoneware for outdoor use, as well as the size of the tiles, depends solely on your taste. The price per m2 of porcelain stoneware for the facade or for the steps depends on the manufacturer and can vary in a very wide range. For example, for domestic manufacturers it can be 700-800 rubles. per sq. m, and for foreign ones - 1000-1500 rubles.

The choice of frost-resistant porcelain stoneware design, tile size depends solely on your preferences

In addition, when choosing, it is necessary to take into account a number of additional material parameters. These include, for example, the caliber - the difference between the size indicated on the packaging with the material and its real dimensions. This difference can be up to 0.5 mm and is of great importance when tiling floors or walls.

It is quite easy to check the quality level of the tiles. To do this, you need to estimate its weight. For example, a tile of frost-resistant porcelain stoneware for the street 30x30 cm with a thickness of 8-9 mm should weigh about 2 kg. If the weight of the material is less, this means that the manufacturer has saved on quality and such a tile will quickly fail.

Features of the choice of porcelain stoneware under the stone

Porcelain stoneware tiles with a stylized natural stone are the most popular, so it is very important to know how to choose this particular type of material. There are options stylized for granite, marble, onyx, sandstone, jasper, basalt and many other types of stones. They are widely used for the manufacture of porcelain stoneware steps for stairs, facade cladding and for other purposes.

The most common are two options for imitating natural stone. It is an accurate imitation and artistic decoration. The first option exactly repeats the pattern and texture of a natural mineral, and the second is characterized by the presence of decorative additives. These include veins of gold, cave painting and so on. In the catalog of ceramic granite by Kerama Marazzi, for example, you can find many similar options.

Advantages of marble and travertine porcelain stoneware

Natural marble and travertine are some of the most popular imitation materials. The imitation of the latter is very difficult to distinguish from the original, even for a specialist, since the tile completely repeats the color and texture of the material. With artificial marble, everything is somewhat more complicated, it is very similar to natural, but does not have the depth of black color that is characteristic of natural stone. At the same time, large tiles look better, for example, laying marble steps from porcelain stoneware for the street using tiles of 1200x600 mm will look better than 600x600.

Subtleties of laying material

The technology of laying porcelain stoneware differs from the installation of conventional ceramic tiles. When laying porcelain stoneware on the street, you should not use cement-based building mixtures, but rather use a special glue. When it comes to finishing the facade, there can be two installation methods:

- Laying on special glue.

- Fastening with brackets or self-tapping screws.

The choice of the method of material fastening depends on many factors. This includes climatic conditions, type of structure and other parameters. Each of the above methods has its own nuances.

The choice of fixing porcelain stoneware tiles depends on many factors, the main of which are the climatic conditions in the region, as well as the type of structure

The choice of frost-resistant glue for porcelain stoneware for outdoor use, the nuances of use

As already mentioned, when finishing surfaces with porcelain stoneware, you cannot use conventional cement-based building mixtures. There are many types of specialized glue specifically for fixing this material. When choosing an adhesive for laying porcelain stoneware outdoors or indoors, you need to pay attention to its following characteristics:

- The glue must necessarily create a strong layer between the sheets of material and the surface. In addition, it has to withstand heavy loads.

- The adhesive mixture must have a high level of moisture resistance, otherwise the coating may deform due to moisture and temperature changes.

- If you plan to lay a material such as porcelain stoneware outdoors, the glue for this must have good resistance to high temperatures.

- The frost resistance of the adhesive must also be at a high level when it comes to laying in a domestic climate.

- Elasticity is another important property of porcelain stoneware glue.

Helpful advice! As a rule, for each type of premises, as well as for interior and exterior decoration, different grades of building glue are needed. Of course, there are universal options, but they will cost you significantly more.

All types of adhesives for porcelain stoneware can be divided into three categories:

- one-component;

- two-component;

- mixtures using a plasticizer.

The peculiarity of one-component frost-resistant glue for porcelain stoneware is that you can work with it immediately after purchase. It has a high level of elasticity and a long curing time. Thanks to the latest quality, you can immediately glue a large number of tiles without the fear that the glue will harden.

Two-component mixtures are called so because when you purchase you get two components of the adhesive mixture. Immediately before applying to the surface, the components must be mixed using a special mixer. Two-component adhesive hardens faster, but is also more durable and elastic.

Plasticizers in the adhesive mixture help to increase its elasticity and extend its service life. If you need high-quality glue for finishing the facade with porcelain stoneware, a cement mixture with plasticizers is your option.

A good option for reliable and high-quality fixing of porcelain stoneware tiles would be a cement mixture with plasticizers in the composition

Facing with porcelain stoneware with glue: recommendations

Different adhesive mixtures are suitable for use in different conditions. For example, for finishing walls and floors in rooms with a high level of humidity, it is better to choose a moisture-resistant compound, and for rooms with high traffic intensity, a compound with high strength characteristics. This will prevent shrinkage and extend the life of the coating.

But when using the technology of laying porcelain stoneware on the street, it is better to use frost-resistant and heat-resistant mixtures that tolerate moisture and direct sunlight well. If you do not want porcelain stoneware steps, walkway or facade to crack after a couple of months of use, it is better to use glue with increased strength and elasticity.

Also note that the larger the tile, the more glue you need to use to fix it. Based on the size of the tile, the thickness of the adhesive layer is also calculated. By the way, the parameters of the spatula, which is used to apply the glue, also depend on the estimated thickness of the interlayer. The thicker the layer, the larger the spatula.

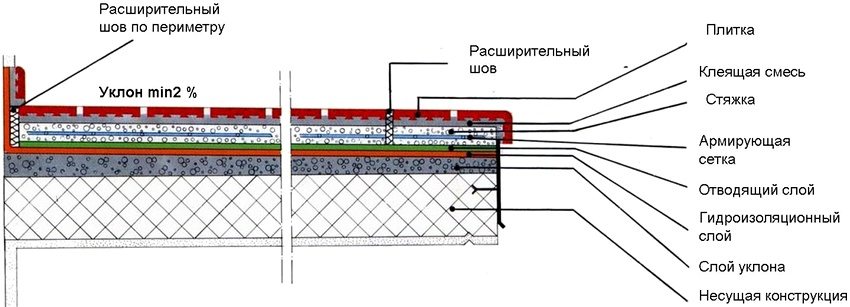

Facade finishing with frost-resistant porcelain stoneware

Facing the facade of a building with porcelain stoneware slabs gives you a number of advantages:

- attractive appearance - there are many options for the appearance of porcelain stoneware tiles, so when finishing you can use your design imagination to the fullest. And, for example, when creating a curtain facade from porcelain stoneware for an office building, you get a respectable view of the building, which will tell all visitors about the solidity of your company;

- protection from moisture - when creating a ventilated facade from porcelain stoneware, natural ventilation is obtained. Thanks to this, mold or pathogenic bacteria do not accumulate in the walls of the building, and in the cold season they do not freeze. All this contributes to a significant extension of the service life of the structure;

- thermal insulation - a ventilated facade reduces heat loss of the entire building. This means that in the warm season they will not overheat, and in the cold air gap will reduce heat loss and, accordingly, the cost of heating the room;

- durability - if you plan to buy frost-resistant porcelain stoneware for the street made in Russia, you should know that this material is characterized by wear resistance, strength, resistance to temperature changes, and also does not require special care during operation. The price of frost-resistant porcelain stoneware for the street 600x600 cm will be higher than that of other finishing materials of the same size, but this is compensated for by high performance characteristics;

- a high level of noise insulation - in combination with an air gap, porcelain stoneware slabs perfectly protect premises from external noise;

- fire resistance - porcelain stoneware is a non-combustible material. Other elements of the ventilated facade belong to the same class;

- ease of installation - the material is easy to install, and it can be done at any time of the year, regardless of weather conditions. At the same time, the laying of porcelain stoneware slabs is done quite quickly;

- the ability to mask the unevenness of the walls without the need for additional plastering work.

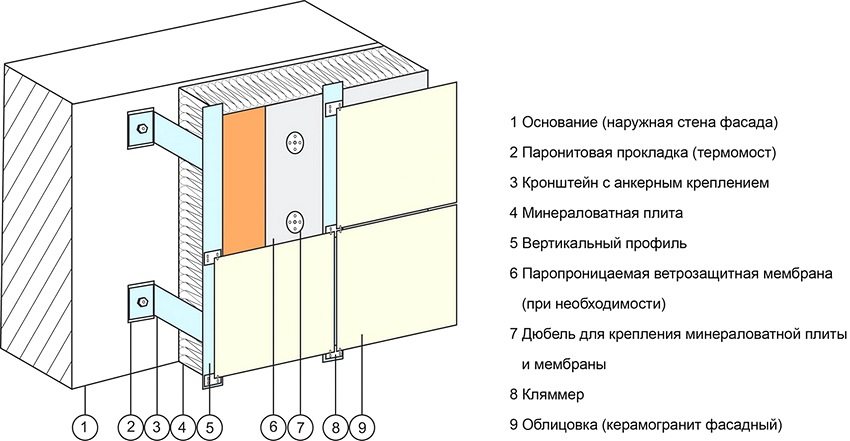

Components of a ventilated porcelain stoneware facade and its installation

With a relatively high price per m2 of a ventilated facade made of porcelain stoneware, you get a large number of advantages that finishing with other building materials cannot give. Any facade consists of the following elements:

- load-bearing wall - acts as a support for the structure;

- sub-facing wall - serves as an intermediate structure between the load-bearing wall, the heat-insulating layer and the finishing material slabs. Consists of brackets that are attached to the wall using dowels and anchors, bearing profiles and special fasteners;

- heat and sound insulation layer - protects walls from temperature extremes, possible thermal deformation, as well as the room from external noise;

- vapor barrier layer - a special film that prevents condensate from settling on the walls and promotes its evaporation;

- air gap - the gap between the insulation and the plates of the facing material. Serves to drain moisture;

- porcelain stoneware slabs - protect all previous layers from negative natural influences, and also perform a decorative function.

Helpful advice! There are several options for attaching the frame system to the load-bearing wall. Choose from them the one that best suits your specific conditions.

The most popular way of attaching porcelain stoneware to the frame system is the combined one. This means that the frame is mounted simultaneously from horizontal and vertical rails. In this case, you can first install either horizontal or vertical. The first method allows you to evenly distribute the load, but it is quite expensive, and therefore is not used very often.

The method in which the vertical guides are first mounted is effective when using thick porcelain stoneware slabs and allows not only to reduce the load on the structure, but also to hide the fastening method.

The type of joints between the tiles of the finishing material may also differ. The visible seam is the simplest option and involves fixing the plates with self-tapping screws, screws or rivets through special seals. Seamless installation involves the use of concealed fixing. There are several variants of it:

- Mechanical - with this method, a hole for the dowel is drilled from the back of the plate. Usually, plates of material with pre-drilled holes are used for mechanical fastening.

- With glue - the material is glued to the vertical profile. This method allows you to reduce the installation time, but you cannot dismantle an already glued (for example, for replacement) plate.

- Combined fastening - carried out in the same way as mechanical, but only at two points and using glue. With this method, the larger the slab, the greater the installation costs.

- With the help of pins - holes for fastening are drilled in the horizontal ends, into which special pins are inserted. The pins are attached to special adjustable brackets that are attached to the load-bearing wall. This option eliminates the use of horizontal or vertical guides.

The use of any of the above mounting methods takes relatively little time, and also allows you to create a high-quality and beautiful facade that does not need additional maintenance.

Frost-resistant porcelain stoneware for outdoor use: installation of porcelain stoneware steps

To make steps from porcelain stoneware, you need to understand that the entire structure must have a number of qualities. First, it must be safe. For this, the optimal step height should be about 15-20 cm, and the width should be 25-30 cm. Secondly, when making steps for a porch made of porcelain stoneware, it must be borne in mind that the material will often be exposed to moisture, therefore it should not slip. Thirdly, the appearance and design of the steps should be in harmony with the appearance of the entire building.

According to the type of material laying, the following steps are distinguished:

- Monolithic - solid slabs, each of which is a step. The traditional size of such steps made of porcelain stoneware is 1200x300 mm. Monolithic steps are characterized by increased strength and attractive appearance, although they are not cheap.

- Prefabricated - made of several medium-sized slabs. Installation of such steps can be carried out in a seam or seamless way.For grouting porcelain stoneware seams outdoors, an ordinary spatula is used, and the seam can serve as a decorative function.

Porch, steps and area in front of the building are decorated with frost-resistant porcelain stoneware tiles

In addition, according to the processing method, several types of porcelain stoneware steps are also distinguished. You can buy the following options:

- polished steps - have a high level of surface specularity, which is 80%;

- unfinished - specularity is 25%, usually used outdoors;

- sanded - good because, due to the matte surface, they do not slip from moisture, are characterized by a high coefficient of friction;

- glazed - combine a high level of specularity and a non-slip surface. They are equally effective indoors and outdoors.

Helpful advice! Glazed boards are better suited for use in rooms with a low level of traffic. For stairs and other places where heavy traffic and heavy loads are expected, it is better to use a matte or polished version.

Facing steps with porcelain stoneware

When laying steps from 1200x300 porcelain stoneware with kapinos or other options for steps, approximately the same procedure is performed:

- The surface of the main steps is covered with an acrylic primer, which improves the adhesion between the facing material and the staircase itself. The unevenness of the steps is leveled with a putty.

- If necessary, the slabs of the finishing material are cut. You can cut porcelain stoneware at home using various tools.

- An adhesive solution is prepared and then applied to the steps. Application is carried out with a notched trowel.

- Plates of material are laid. It is better to start with the upper steps. The horizontal elements are laid first, and then the vertical elements.

- The corners of the steps are processed using a plastic or metal corner.

- The joints between the plates are filled with grout and cleaned.

The price of porcelain stoneware steps for stairs depends on the type, size and other characteristics of the material. For example, the price of Estima porcelain stoneware can vary from about 300 to 800 rubles. per sq. m.

Waterjet cutting is used to cut curly products, create delicate and exquisite patterns and ornaments.

Features of waterjet cutting of porcelain stoneware and other processing methods

Often, when installing porcelain stoneware, the material has to be cut. This can be done in various ways. For example, you can use a special machine for cutting porcelain stoneware. It can be electric or manual and allows you to cut hard material neatly. The machine uses special blades for cutting diamond-coated porcelain stoneware.

It should be understood that with the help of a machine it is convenient to cut slabs into large pieces, but to cut shaped products, you will need laser or waterjet cutting. The first method is carried out using special industrial lasers, and the second is a jet of water with abrasive materials. Waterjet cutting is cheaper than laser cutting, but at the same time it produces good results.

To use waterjet cutting, you also need a special machine, but with its help you can get delicate ornaments or exquisite patterns from porcelain stoneware slabs.

It is not without reason that porcelain stoneware is one of the most demanded finishing materials on the modern market. It boasts high performance, a variety of design options, and ease of installation. Choosing a porcelain stoneware finish, you choose quality, reliability and an attractive appearance.