From this article you can find out what properties and technical characteristics hammer paint for metal has: distinctive features of the material, scope, advantages and disadvantages, list of components and their functional purpose. The text discusses in detail the existing varieties of coatings, their parameters and prices, as well as the step-by-step technology for painting surfaces.

Hammer paint for interior and exterior use is suitable for painting rusty unpainted and painted surfaces

Content [Hide]

- 1 Hammer paint for metal: basic information on compositions

- 2 Application of hammer paint for metal: colors, photos and prices

- 3 Hammer paint technology on metal: how to paint correctly

- 3.1 Popular tools for removing old paint and rust from metal

- 3.2 How to paint Hammerayt with hammer paint: choosing the right tool for the job

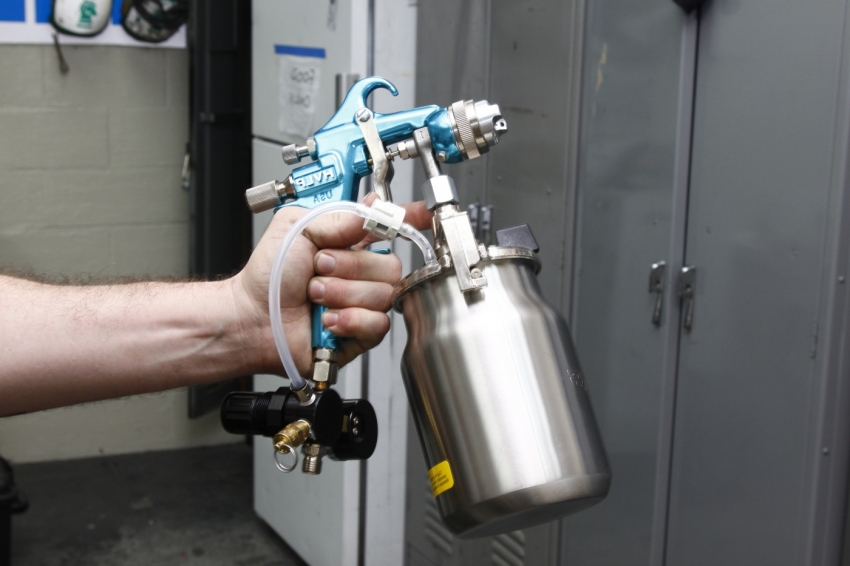

- 3.3 Hammer paint application on metal Hameright with a pneumatic spray gun and a spray gun

- 3.4 Spray and roller hammer paint Hammerite

- 3.5 Using a Hammerayt Paint Brush

Hammer paint for metal: basic information on compositions

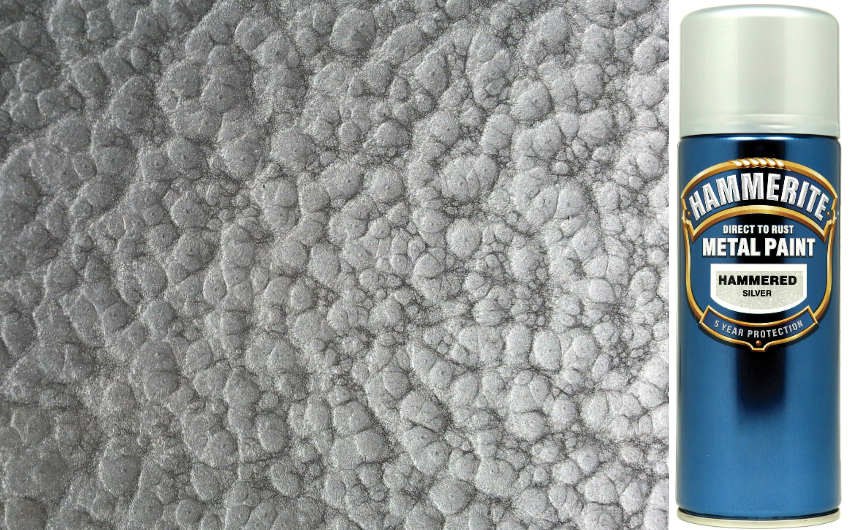

Hammer paint got its name from the decorative effect inherent in this type of coating. The surface treated with the compound looks like metal chasing, made by hand with a blacksmith's hammer. This type of finishing material has been developed specifically for the processing of equipment used in laboratories and manufacturing plants. For this reason, there was no need to pay attention to decorative characteristics, the color range of dyes was previously represented by an exclusively gray tint.

Hammer paint for metal hides irregularities on the surface, so it can be used to re-tint the product

Due to its high resistance to corrosion and negative external factors, hammer paint has become popular and in demand, and its color palette has been significantly expanded.

Definition of hammer paint: what kind of composition it is, what components it contains

To understand the properties of the coating, you need to figure out what hammer paint for metal is and what components it includes. The composition is extremely durable.The dye is made using styrene alkyd, acrylic and epoxy components. In addition, the composition contains fillers in the form of fine-grained glass and aluminum powder, as well as silicone oil. In a liquid state, the finished dye has increased adhesion. It quickly sets on the surface, and after drying, a very high-quality and durable coating is formed.

Note! The high density of the mixture is ensured by the presence of metallic powder in the composition. As a result, the coating is durable, but the application of hammer paint with a spray becomes problematic.

When hammer dyes began to be used not only for protective, but also decorative purposes, manufacturers added color pigments to the mixture. The combination of fine glass, aluminum powder, silicones and aluminum flakes enhances the waterproofing and texture of the coating.

Why is it profitable to buy hammer paint for metal: the advantages of the material

The unique composition of the finishing material ensured its relevance in the market. A good hammer effect metal paint has many benefits:

- high resistance to temperature extremes, which allows the coating to withstand high temperatures (up to 80 ° C);

- there is no need for preliminary preparation of a rusty surface; priming and cleaning can be dispensed with;

- fast and easy staining system;

- lack of stickiness;

- fast drying period (the dye after aerosol application dries up after 2 hours);

- resistance to negative effects of environmental factors;

- vibration resistance, allowing the use of dye for processing equipment walls, metal fences, garage doors;

- long-term anti-corrosion protection of metal - up to 8 years;

- safety for human health;

Hammer paint is practically invisible in places where the product is tinted, in case of damage to the main paint layer

- after full drying, the coating does not emit toxic substances into the air;

- the ability to use different tools for application, for example, a brush, roller, aerosol;

- lack of unpleasant odor;

- the possibility of using a dye for interior finishing work;

- an extensive selection of colors;

- maintaining an attractive appearance for 3 years;

- the coating is excellent at repelling dirt, so that hammer paint can be used for finishing garage doors.

Helpful advice! If you use an aerosol application, you can control the consumption of the dye.

Scope of application of paint for metal with hammer effect

The unique properties and improved characteristics have made hammer enamel popular and widely used.

Thanks to the aluminum flakes in the hammer paint, the finished product has a special "patterned" pattern

This type of dye is used to treat various objects:

- industrial equipment;

- body part of machine tools;

- drainage elements, flagpoles;

- garden tools, fittings, weather vanes;

- specialized devices;

- electrical panels;

- building structures made of metal;

- metal cabinets, safe structures;

- shelving and office furniture;

- agricultural equipment and machinery;

- fences and gates.

Hammer dye is also used as a decorative coating for decorating products made of tiles, durable plastic, glass. Most often, the composition is applied to gazebos, fences and gates that need anti-corrosion protection.Hammer paint looks most attractive on metal products made by forging. The coating gives them an original texture and enhances the shine.

The scope of application is not limited to landscape design, as the dye is suitable for interior surfaces. After applying the composition on the surface of products made of non-ferrous or galvanized metals, steel, a reliable anti-corrosion barrier is formed.

Application of hammer paint for metal: colors, photos and prices

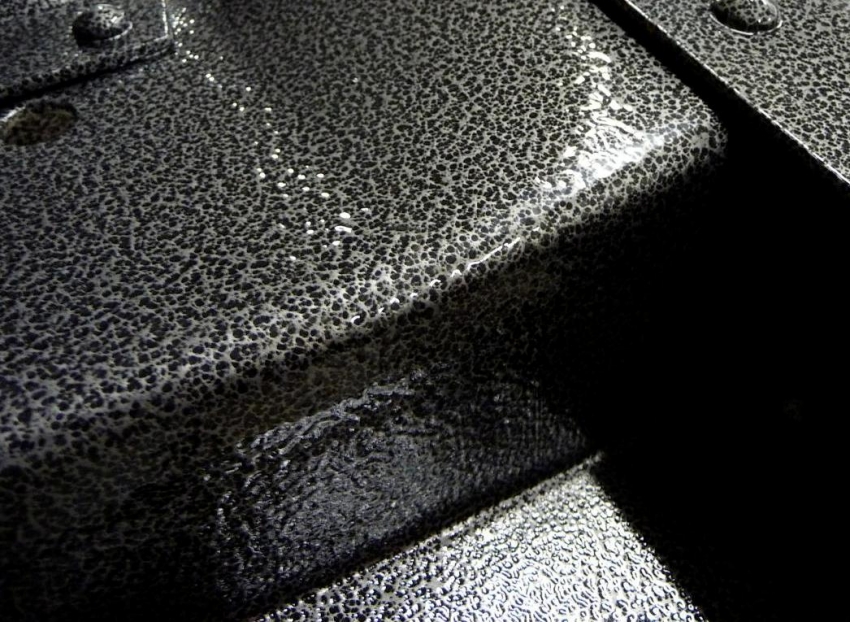

The hammer effect dye works best on horizontal surfaces. When applied to vertical surfaces, the composition will drain. In addition, it will not be possible to achieve the characteristic pebbled effect. Therefore, it is preferable to consider the possibility that the workpiece will need to be set horizontally during staining. If this is not possible, it is advisable to buy a quick-drying composition that does not have time to spread too quickly over the surface.

The dye color palette includes the following shades:

- brown;

- Navy blue;

- red;

- blue;

- light green;

- golden;

- copper;

- Gray;

- silver gray;

- the black;

- dark green.

The price of hammer paint for metal depends on the manufacturer, drying time and other characteristics.

Due to its high anti-corrosion performance, hammer metal paint is widely used for coating apartment entrance doors

Helpful advice! If it is supposed to paint a new metal, it is imperative to remove a layer of factory grease, which exposed the surface of the material.

Popular brands of hammer paints for metal: prices of compositions and their features

One of the most popular paints is ML-165. It is an enamel made on the basis of styrene alkyd components. The composition of this brand has a high level of temperature resistance and excellent adhesive properties. The surface is able to withstand temperatures up to 130 ° C. To remove this type of coating, it is recommended to purchase xylene, which dissolves ML-165 perfectly. For the composition, there is no limitation on the surface to be applied.

EP-1323ME can be used as a primer paint for metal. This epoxy enamel has the properties of both a dye and a primer. This type of coating is optimal for processing the following objects:

- body part of loaders and truck cranes;

- elements of cars;

- constructions of gates, fences and doors.

It is allowed to use EP-1323ME over rust... Suitable solvents are 667 and 648.

Hammer nitroenamel NTs-221 belongs to the budget options of the dye. This type of coating is incapable of fully performing a protective function, it has a decorative purpose. Therefore, it is not allowed to apply the composition over rust, and its temperature resistance index is not higher than that of a conventional dye. NTs-221 is successfully used for both external and internal types of work.

No less popular are Hammerite compositions belonging to the expensive segment of coatings. This English-made dye is in high demand in the market and can be applied over rust.

Average prices for hammer paints:

| Name | price, rub. |

| NTs-221 | from 92 |

| EP-1323ME | from 183 |

| ML-165 | from 217 |

| Hammerite | from 466 |

Features of paint for metal in a spray can: sprays of popular brands and prices

Hammer dyes have different types of packaging, including in the form of cans. Compositions from the BOSNY trademark are distinguished by their ease of use, like any finishing material in the form of a spray. Thanks to this method of application, you can dose the dye and reduce its consumption.This type of coating is completely safe and has long shelf life and fast drying. It is allowed to apply the composition over a surface covered with a small amount of rust.

Note! BOSNY dye does not contain mercury and harmful metals (lead).

The Hammerite effect dyes create an excellent decorative coating. In this case, the surface is obtained with a pronounced shagreen, which is characterized by a muted shine. The hammer effect, when applied uniformly, appears over the entire treated area. This type of dye belongs to the category of finishing materials 3 in 1. Also, the composition contains anti-corrosion components. The Hammerite effect paint can be applied to rusty objects, and in the presence of loose thick-layer corrosion, preliminary cleaning of the surface for painting is required.

The Italian dye Idea Spray Maimeri is equipped with a high-quality spray gun, so it can be used even for processing delicate decorative details on metal products. This type of product has a high coverage rate, dries quickly and fits well on the substrate.

Average prices for metal spray paints:

| Name | price, rub. |

| Hammerite effect | from 160 |

| BOSNY | from 345 |

| Maimeri idea spray | from 662 |

Related article:

Heat-resistant paint for metal and its scope

Scope, features and varieties of compositions, their advantages and disadvantages. How to choose a material for processing a stove and barbecue.

What is the paint consumption for hammer effect metal

The consumption of the dye depends not only on a specific manufacturer and its composition, but also on external factors:

- Weather conditions.

- The tool used.

- The quality of the processed surface.

- Features of the dye.

If the painting is carried out in hot weather or direct sunlight is directed at the object, the liquid in the composition will evaporate much faster. As a result, the consumption will increase by 1.5 times. Strong gusts of wind provoke the appearance of defects in the form of irregularities and stripes on the surface, which also affects the consumed volume of the dye, increasing it by 20%. In such conditions, it is impossible to apply the composition in a thin layer.

Using spray gun as a paint application tool can be a good way to save money, but only if you have experience in painting. Otherwise, the desire to reduce costs will turn into an overhead.

This may be due to:

- Uneven application.

- Weathering of the composition.

- Leakage formation.

Brushes are characterized by increased absorbency, so their use increases paint consumption. This is especially true for tools with nylon wraps. The best option is a roller with a properly selected fur coat. The rougher the surface, the longer the pile should be.

Consumption of popular dyes:

| Name | Dye consumption, l / m² |

| NTs-221 | 0,105 |

| ML-165 | 0,11 |

| Hammerite | 0,2 |

| EP-1323ME | 0,2 |

| Maimeri idea spray | 0,2 |

| BOSNY | 0,4 |

Note!Dye consumption does not always correspond to the information indicated on the package. This value is always approximate as it is influenced by many factors. All of these points should be taken into account when calculating the minimum amount of paint. Average consumption of hammer dye is 150 ml / m².

Hammer paint for metal is one of the most popular materials for coating forged fences, beautifully highlighting all the details of the product.

The use of hammer paint for metal: customer reviews

Many consumers give preference to hammer dyes when it becomes necessary to process metal products on the street. Most of the reviews left by buyers on the forums note the benefits of these formulations:

“I thoroughly treat the issue of arranging my home, so I select all building and finishing materials very carefully. Judging by the reviews, Hammerite dye, despite such a high cost, justifies the costs. I have come across negative comments, but most often they were associated with a violation of the application technology, in particular, improper surface preparation. Therefore, I decided to dwell on this particular dye and I must say I was not mistaken with the choice. Excellent coating with a long service life, and combines several functions at once. Since I tried it, I recommend it to everyone. "

Evgeny Zheltukhov, Moscow

“At one time I had a chance to test the Italian quality of finishing materials in practice. Textured paints proved to be good not only during application, but also during operation. So I chose the Italian manufacturer of hammer paint Maimeri to paint the metal gazebo. Using a handy spray with a fine, economical spray, I was able to completely spray a wrought-iron piece in half a day. All the neighbors are delighted with the result, as I am. This colorant is definitely worth the cost. "

Alexander Petyakhin, Yekaterinburg

Hammer paint technology on metal: how to paint correctly

The technology for applying hammer dye depends on the selected composition, the type of surface to be treated, and the degree of corrosion damage. If it is intended to paint a new metal with a smooth surface, the preparation consists in the complete removal of the factory grease. To do this, it is recommended to wash the base for painting with a greasy solvent. A solvent or white spirit will do. The surface is processed at least 2-3 times. The base is then wiped off with a volatile solvent such as acetone.

To check the quality of removal of grease, the surface should be blotted with filter paper. If greasy spots appear on the material, you need to repeat the above procedure.

Helpful advice! If you have to work with a shiny and smooth substrate, you need to take measures to increase the adhesive properties of the dye. To do this, it is recommended to treat the surface with a metal brush or sanding paper, making it rough.

For coloring batteries and boilers, it is worth using heat resistant hammer paint for metal

Hammer paint works well with other finishes. The exception is powder compositions and materials containing bituminous additives. It may only be necessary to remove loose pieces of paint or rust.

Popular tools for removing old paint and rust from metal

Flakes of rust and old paint can be removed manually or mechanically.

Recommendations for mechanical surface cleaning:

- For cleaning, you will need a grinder or a drill with a set of metal brushes.

- The size of the brush is selected taking into account the shape of the object and its area.

- After processing a metal surface, it is imperative to check the quality of the result.

- Particular attention should be paid to hard-to-reach places, such as corner joints, bends or joints. If necessary, you need to walk through them again.

If, after mechanical cleaning, traces of peeling rust remain on the surface, the base must be finished by hand using brushes designed for cleaning metal products.

Powder colorants with which hammer coatings are incompatible are removed by the following methods:

- chemical;

- sandblasting;

- water jet.

- burning.

The most effective way to remove powder coatings is to use chemicals. In such cases, you can buy a paint remover from metal Remover for steel and aluminum products or Fail-4 (consumption 0.12-0.25 g / m²), which is also used for cleaning concrete, plaster, wood and stone surfaces. When using chemical washes, it is imperative to use protective measures: gloves, glasses, a respirator.

How to paint Hammerayt with hammer paint: choosing the right tool for the job

After the surface is prepared, you need to decide on the application method and choose the appropriate tool:

- brush;

- airless spraying;

- roller;

- aerosol can;

- spray gun;

- pneumatic spraying.

The choice of tool depends on the size and shape of the object, the presence and number of welds. It is advisable to use an aerosol can in cases where painting or renewal of a small area with a flat surface is required. For products with a complex configuration, it is better to choose a brush. Such products include: structures with a large number of welded seams, benches and fences, curly lattices and forged products.

Helpful advice! For coloring products with complex shapes, it is better to use a brush with natural bristles.

Flat surfaces with a large area can be handled by a spray gun and a roller. These tools are designed for painting door structures, gates and blind metal fences, iron roofs.

Hammer paint better adheres to horizontal surfaces, therefore, if such painting is impossible, it is better to use a spray gun or a spray gun

At the preparation stage, you should also take care of how to dilute the hammer paint. Moreover, for these purposes, the funds used for conventional formulations are not suitable. Use diluents recommended by the manufacturer, preferably of the same brand.

Hammerite Brush Cleaner & Thinners pricing:

| Volume, l | price, rub. |

| 0,25 | 211 |

| 0,5 | 365 |

| 1 | 542 |

| 2,5 | 962 |

Hammerayt thinners are effective and safe. They are suitable for indoor and outdoor use. If the product is used inside, be sure to provide good ventilation. Thinners are also used for surface cleaning, removing oil, grease, paint stains and cleaning tools after painting.

With Hammerite Brush Cleaner & Thinners, you can not only prepare surfaces for painting, but also treat tools after use.

Hammer paint application on metal Hameright with a pneumatic spray gun and a spray gun

A high-quality result of painting with a spray gun or pneumatic spray is possible only if several conditions are met:

- The surface must be clean and smooth.

- Using the tool requires skill.

- Correctly selected dye viscosity.

According to the instructions, the optimal viscosity of Hammerite dye can be achieved by mixing the composition with Brush Cleaner & Thinners in a 2: 1 ratio, respectively. Since the air temperature also affects the viscosity index, such proportions may not always be correct. Therefore, you will have to check the readiness of the paint for application by the method of tests or using a special device - a viscometer.

The solvent is added to the paint until the mixture, after stirring with a wooden spatula, drips from it, and does not drain. Optimum flowing consistency is 1 drop / sec.

Due to metal flakes in hammer paint, attention must be paid to selecting the correct size of the spray gun nozzle

It is recommended to filter the composition before staining.Spraying is done in several layers. It is recommended to apply the dye to the surface 3-4 times. At the same time, the first layer should be as thin as possible in the form of spraying, the last layer should be made thick, but within reason, so as not to spoil the result.

Helpful advice! Special attention should be paid to vertical surfaces. Their staining should be as fast and accurate as possible. The recommended break between applications is 20-30 minutes. The optimum distance between the tool and the surface is 15-20 cm.

Spray and roller Hammerite paint application

Before you start staining, you should thoroughly shake the can so that the mixture inside is well mixed. As in the case of a spray gun and a pneumatic spray gun, the can should be located at a distance of 15-20 cm from the surface to be treated. The required number of layers - 4. The principle of applying the composition is similar, only the drying time changes. The initial thin coat dries in about 2-3 minutes. Subsequent layers require longer intervals - from 15 to 20 minutes.

If a roller is chosen as a tool for applying dye, you should take the product with a fur or woolen coat with a short nap. It also helps to use a paintbrush to help work on areas that are difficult to reach, such as corners and edges. When applying paint with a roller, 2-3 coats are sufficient. In this case, be sure to use the original Brush Cleaner & Thinners for the first coat. The recommended proportion is 1: 9. Then you can refuse it.

Using a Hammerayt Paint Brush

The brush belongs to the category of universal tools for applying dye. However, there are situations in which the use of other processing methods is not possible. Flute brushes with natural bristles are the best option.

First you need to process all bends, corners and edges, welds and small elements. It is with them that corrosive damage to metal products usually begins. With the help of a brush, two or three layers of Hammerayt dye are applied. If the product is decorated with small exquisite elements, you will need to repeat this manipulation 5-6 times. However, there is a limitation, the total coating thickness should not exceed 100 microns.

It is more convenient to paint hard-to-reach areas with many bends using a brush or a small roller with a long nap

If you use a brush with synthetic bristles, this material will melt, because hammer dyes contain organic solvents. Regardless of the chosen paint and method of application, the surface to be treated must be clean. Only in this case the hammer coating will reliably and evenly lay on the base and will last a long time.