This article discusses drainage pipes for groundwater disposal: a complete classification of drainage products, their advantages, characteristics and basic parameters is presented. With this information, you will learn how to select the appropriate types of pipes for certain types of discharge systems in accordance with their requirements, soil characteristics, etc.

Content [Hide]

Drainage pipes for groundwater disposal: an introduction to the topic

The drainage pipe acts as the main building element, on the basis of which a drainage system is formed, designed to drain the areas. This element is responsible for collecting and discharging underground, melt and rainwater outside the territory with their preliminary filtration.

Note! A large volume of melt and storm water can provoke a rise in the level of groundwater. The emergence of such a situation is extremely undesirable, since as a result, the destructive effect on the foundation part of the building, as well as all the elements of landscape design located on the site, increases.

Drainage system helps to get rid of excess water in the area

Installation of large diameter drainage pipes allows you to cope with such problems as:

- increased soil moisture;

- mold formation;

- flooding of the site, the foundation of a residential building and utility buildings, as well as cellars;

- formation of permafrost;

- the appearance of puddles on paved surfaces;

- formation of ice on footpaths;

- decay of the roots of garden flowers, vegetables and other vegetation due to an excess of moisture in the garden and summer cottages.

Features of drainage pipes with partial perforation, complete or lack thereof

If we talk about the general classification of products for drainage systems, the range is represented by the following types of pipes (by type of material):

- asbestos-cement;

- ceramic;

- plastic drainage pipes with and without perforation, as well as with its partial presence.

On the building materials market, drainage pipes are presented in a wide variety of types and sizes.

However, most construction companies have already abandoned the use of pipes made of ceramics or asbestos cement due to the numerous disadvantages inherent in them:

- Large weight, requiring significant costs for transportation and installation, because the installation of such bulky products cannot do without the use of specialized construction equipment.

- The slow process of installing a drainage system, which can only be carried out by the hands of professionals.

- Low performance. Drainage pipes are usually on sale without perforation, so the holes are made by hand. Because of this, during operation, the pipeline becomes clogged faster, so frequent cleaning is required, and in some cases, complete replacement of elements.

- The construction of systems based on them is much more expensive than in the case of using plastic elements.

Installation of a water drainage system on a land plot using corrugated plastic pipes with perforations

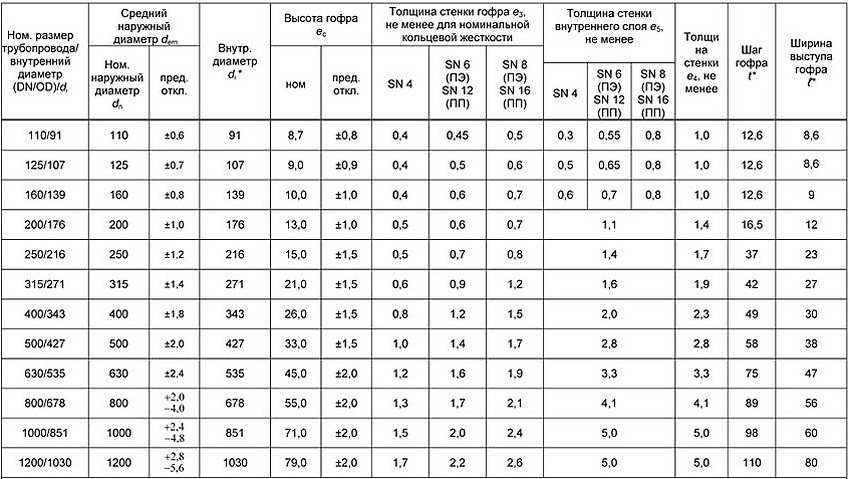

Note! The table shows the average price of drainage pipes 200 mm from various materials. There are other diameter options, however, in products made of ceramics, asbestos cement and plastic, the standard dimensional parameters do not coincide. Therefore, for comparison, the diameter of the drainage pipe is taken as 200 mm, which is present in the range of all these products.

Comparative pricing table:

| Material type | Price, rub / rm |

| Asbestos cement | 258,2 |

| Ceramics | 650 |

| Plastic | 237 |

Advantages of plastic drainage pipes: HDPE and PVC

Polymer products (plastic) are in many ways superior in performance to asbestos-cement and ceramic products for drainage.

List of their advantages:

- Long service life.

- High strength index.

- Complete invulnerability to corrosion.

- Light weight, which facilitates not only the transportation process, but also the installation procedure, as well as accelerating its completion time.

- Due to the presence in the assortment of a large number of connecting elements (fittings, tees, etc.), the installation of the system is fast, reliable and convenient.

- The smooth surface prevents dirt from sticking, delaying the clogging process.

- The use of drainage pipes in geotextiles of 200 mm or more eliminates the possibility of silting up the system.

- All installation work can be done by hand, since this does not require special education, construction machinery and special equipment are not needed.

Using the example of corrugated PVC pipes with a diameter of 200 mm, you could see that the cost of these products can also be attributed to the significant advantages of plastic products.

The range of plastic pipes includes several product categories:

- polyvinyl chloride;

- polyethylene;

- polypropylene.

The most popular on the market are PVC drainage pipes.

Features of PVC drainage pipes: product classification according to different criteria

Products made of PVC and other polymeric materials can be divided into the following categories:

- two-layer and single-layer;

- flexible pipes (produced in coils, the length of which is 40-50 m);

- rigid products for drainage systems (their length is fixed, the range includes pipes from 6 to 12 m in length);

- products with different strength classes (letter marking SN: 2,4,6,8,16);

- pipes with and without filter wrap.

Note! The table shows the average price of a drainage pipe in a geotextile filter 200 mm with perforation and corrugated surface. This figure may vary depending on the manufacturer.

Prices for drainage pipes 200 mm (in geotextile and without it):

| Item type | Coil length, m | Price, rub / piece |

| Single layer, corrugated, perforated, geotextile (SN4) | 40 | 8400 |

| Double layer, corrugated, perforation, geotextile (SN6) | 40 | 13500 |

| Single layer, corrugated, perforation | 40 | 9500 |

| Double layer corrugated perforation | 40 | 12000 |

| Single layer (SN4) | 40 | 9000 |

Products on sale can have a diameter of 50 to 200 mm. There are also more massive options related to large diameter drainage pipes.

Characteristics of perforated drainage pipes

Flexible single-layer perforated products can be used at depths of no more than 3 m. The pipe class also indirectly indicates the recommended laying depth. In the case of SN2 pipes, the depth should not exceed 2 m, SN4 - no more than 3 m.

Double-layer pipes have a smooth inner surface. In this case, the outer side is corrugated. Typically, such products have SN6 ring strength. When arranging a drainage system, segments with a length of no more than 4 m are used. Coconut fiber or geotextiles can be attached to them as a filter. There are products on sale without a filter.

Corrugated perforated drainage flexible pipes are marked with SN8 class. Supplied complete with filter material and without it. Designed for deep filling - up to 10 m. Two-layer products of the same class allow the system to be buried no more than 8 m. They are made without a filter.

Average price of drainage pipes 160 mm and 110 mm with perforation and corrugation (3 m):

| Name (manufacturer) | Diameter size, mm | Price, rub / piece |

| Perfokor (Russia) | 110 | 900 |

| Perfokor (Russia) | 160 | 1945 |

| UPONOR (Finland) | 110 | 1200 |

| UPONOR (Finland) | 160 | 3450 |

Features of Perfokor products: products for drainage systems

Perfocor pipes are successfully used for water drainage. Perforations on their surface allow water to penetrate into the product. After that, it is transported further through the sewer system or is discharged into an artificial or natural reservoir.

The scope of application extends to construction:

- buildings for various purposes;

- roads;

- stadiums;

- airports;

- as well as land reclamation.

Note! The holes on this type of pipe are optimally sized, large enough to allow water to pass through the system, but small enough to prevent the ingress of earth, debris, silt and other particles that can remove sewerage out of service.

Connection of corrugated perforated drainage pipes Perfokor is carried out in several ways. For this, a combination of a coupling and an O-ring or butt welding can be used.

Due to the fact that the rubber gasket is placed inside the corrugation during the connection of the system elements, this part cannot move during the installation process. The rubber gasket for the connection has the same profile as the pipes. Therefore, the likelihood of pipeline leakage, as well as the ingress of groundwater inside, is excluded.

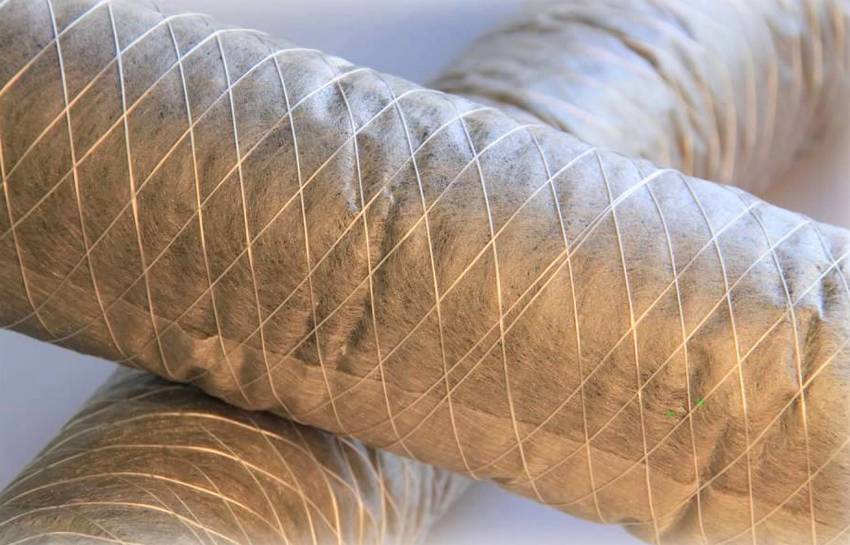

Specificity of corrugated perforated drainage pipes with geotextile

Various types of filters are used as an effective addition to the pipeline, increasing its operational life. Such materials include geotextile fabric and coconut fiber.

Drainage pipes corrugated perforated with geotextile 160 mm and more are products with a large number of rationally located holes, as well as stiffeners. These small holes are placed in the trough that forms between the corrugation waves.

The stiffeners ensure an even distribution of the pressure exerted by the soil on the pipe.Due to the fact that the load is distributed over the entire length of the pipe, the drainage system can withstand not only the soil pressure, but also all additional loads that arise.

These types of pipes are used for laying a pipeline at a depth of 0.7-6 m.Thanks to the large number of holes that fall per 1 m. On the special profile of the product, water is quickly collected, passed through the entire system and drained outside the suburban area ...

Note! Plastic products are light enough, so they can be considered as the best material option for creating a drainage system with your own hands. The bay is 40 m long and 160 mm in diameter and weighs about 25 kg.

The price of a drainage pipe in a geotextile filter 160 mm, 90 mm and 110 mm:

| Manufacturer | Item type | Diameter, mm | Coil length, m | Price, rub / piece |

| TYPAR with HDPE filter (Russia) | Single layer SN4 | 90 | 50 | 4200 |

| Single layer SN4 | 110 | 50 | 3200 | |

| Single layer SN4 | 160 | 50 | 5800 | |

| Double layer SN6 | 110 | 50 | 7300 | |

| Double layer SN6 | 160 | 50 | 10600 | |

| NASHORN | Single layer SN4 | 110 | 50 | 4500 |

| Single layer SN4 | 160 | 50 | 7000 |

Diameters of drainage pipes and features of the use of their elements

If you undertake to create a drainage system on a site with your own hands, the following recommendations should be taken into account:

- The effectiveness of the system depends on how correct your choice is in terms of pipe diameter.

- A perforated product with a diameter of 110 mm is able to drain the area from water within a radius of 5 m. This information should be taken into account in the design of the drainage scheme.

- The pipes must be laid with a slope in the direction where the well or septic tank will be installed.

- The process of connecting all elements of the pipeline must be technologically correct.

Pipes with a diameter of 63 mm are used on a par with 110 mm products. Each such element has a network of small holes.

Experts recommend buying a drainage pipe 63 in a geotextile filter for use in areas that are located in lowlands or in areas where there is a high level of groundwater. This material can be used for arranging drainage during the construction of a cellar, an underground garage, as well as modern cottages with a basement.

Note! The choice of the pipe diameter directly depends on the depth to which the drainage system will be buried. For example, products with a diameter of 63 cm can effectively perform their work at a depth of 8 m. For depths exceeding this indicator, they will not work.

Choosing a pipe for a drainage system by the type of soil on the site

The foundation of any structure can be washed out by groundwater even at a depth of 1.5-2 m. Groundwater includes components that can destroy the foundation. Waterproofing in such cases is powerless, so you have to resort to more drastic measures - the construction of a drainage system. In this case, the type of soil should be taken into account, as well as the degree of its moisture.

The construction of a drainage system will protect the foundation of the house from erosion by groundwater and storm water

An increased water content in the soil can lead to freezing and decay of plants, the appearance of fungi on them and on fruit trees, as well as to waterlogging of the territory. In this case, it is recommended to use corrugated pipes made of polyethylene. With their help, you will provide a budgetary and fast drainage system that will relieve groundwater pressure and significantly reduce its level.

Soil types and optimal materials:

| Soil type | Recommended material for drainage |

| Crushed stone | products with perforation without filter material |

| Sandy | pipes with a filter made of geotextile fabric + crushed stone embankment |

| Clayey | pipes with or without filter + rubble embankment 0.2 m thick |

| Loamy (combined) | geotextile filter products |

Characteristics of plastic drainage pipe 300 mm

Plastic pipes for drainage systems have established themselves as durable, reliable products. They are economical and efficient. The use of polymer products can significantly reduce the cost of electricity and money for drainage of the site. Such a system can last for 40-50 years.

The technology of arranging the drainage system involves the use of filter materials, as a rule, geotextiles.

Plastic pipes as elements of a water drainage system are gaining more and more popularity due to their high strength and reliability.

Note! Pipes with a diameter of 63 mm to 250 mm are sold already wrapped in geotextiles. Large diameter products are used for construction in industrial facilities. They also require a geotextile wrap, which in this case is done by hand.

The average price of a drainage pipe of 300 mm made of polymers is 200-300 rubles / m. p. If the products do not have sockets, their cost is reduced by about 50-100 rubles. In drainage systems, similar options for cast iron pipes are used. Their cost is in the range of 350-450 rubles / m. P.

Regardless of the size of the products, the system is always installed at an angle and in each case it is worth adhering to certain parameters. Installation of pipes with a diameter of 300 mm is carried out with a slope of at least 3 mm. Since this type of product can meet the stiffness classes SN6 and SN8, the pipeline can be laid to a depth of more than 2 m.

Feature of Large Diameter Ditch Drainage Pipes

The choice of pipe diameter also depends on the flow of groundwater. In other words, the selection of products for a drainage system is based on an indicator that reflects the amount of water that passes in 1 second.

Other factors also matter here:

- groundwater level;

- the amount of excess moisture;

- the nature of the landscape.

Drainage pipes PVC corrugated with a diameter of 500 mm, 400 mm and 630 mm are two-layer products. Their double walls are corrugated on the outside and smooth on the inside.

Due to the presence of corrugation, the pipe walls exhibit high resistance to the occurrence of any deformational changes under the influence of loads. In the assortment of the modern construction market, you can find products that correspond to the following classes of ring stiffness:

- SN4;

- SN8;

- SN16.

This variety allows the pipeline to be laid at different depths. Large diameter polymer pipes have a wide range of operating temperatures. The extreme points correspond to -40 ° С and + 60 ° С.

Average price of drainage pipes 400 mm, 500 mm and 630 mm (Perforated):

| Item type | Diameter, mm | Length | Material | Price, rub / piece |

| Double layer SN8 | 400 | 6 | HDPE | 2600 |

| Double layer SN16 | 400 | 6 | HDPE | 3590 |

| Double layer SN8 | 500 | 6 | HDPE | 3800 |

| Double layer SN16 | 500 | 6 | HDPE | 5350 |

| Double layer SN8 | 630 | 6 | HDPE | 5250 |

| Double layer SN16 | 630 | 6 | HDPE | 7230 |

Useful advice! The construction of a highway to drain excess moisture from the site is not the only area of application for such products. Use pipes with a large diameter as drainage wells to monitor the condition of the drainage system, as well as to clean it.

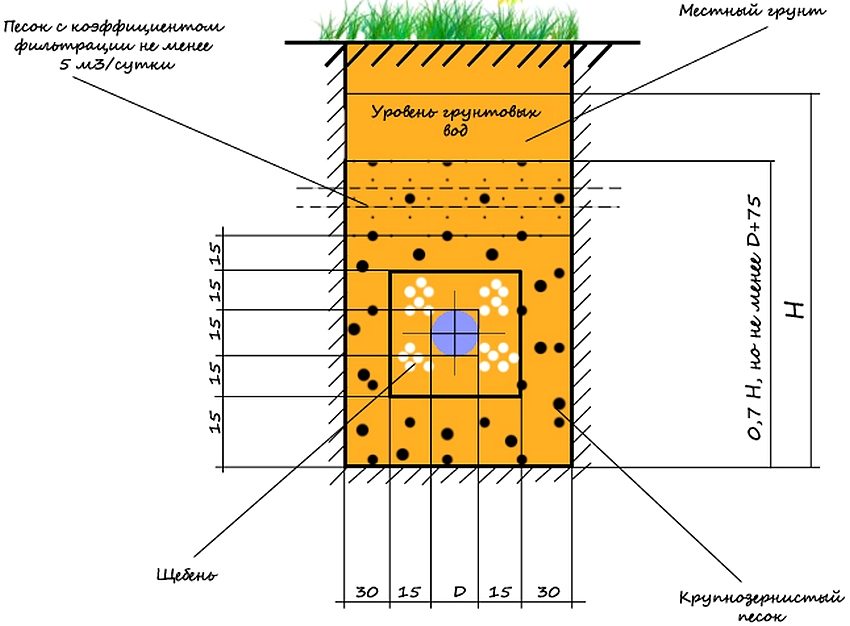

Additional tips for using pipes

Construction of the drainage system on the site is most often carried out simultaneously with its development. In order for the drainage system to function, it is necessary to organize the maximum flow of water to it. The indicator that determines the access of moisture to the pipeline is called the permeability of the soil. To increase it, sprinkling with special filtration materials is used.

Such materials include:

- gravel;

- crushed stone;

- pebbles.

Thanks to the filter, the volume of liquid from the section entering the system increases. To prevent the drainage system from filling up with silt and dirt, the speed of water flow through the pipes must be at least 0.2 m / s.

Common mistakes when laying a drainage system:

- the use of pipes that are not intended for installation in a certain type of soil (for example, using a pipe without a geotextile filter on loamy soils);

- lack of filtering dust;

- lack of necessary slopes;

- backfilling of trenches with non-filtering soil;

- untimely removal of the accumulated liquid from the collection well.

The effective operation of the drainage system depends not only on adherence to the installation technology, but also on the maintenance of the pipeline during further operation.

For the effective functioning of the drainage system, it is necessary to organize the maximum water flow to it.

Maintenance of the drainage system involves regularly checking the system for blockages and malfunctions, and eliminating them if they are detected. In addition, it is systematically necessary to monitor the state of the groundwater level in the territory of a suburban area in order to know how effectively the sewage system copes with the removal of excess moisture. It also does not hurt to check the quality of groundwater.

Due to the timely implementation of scheduled repair and preventive work, as well as troubleshooting, you can not only increase the service life of the pipeline, but also eliminate the likelihood of accidents.