PVC film for the pool is a modern coating that is widely used in its decoration. The material simultaneously performs two functions: waterproofing and decorative. It transforms the tank into a blue-blue airtight bowl. What types of products exist, how to choose the right film for the pool and how to finish it, is detailed in this article.

The PVC film for the pool is a modern material that performs decorative and waterproofing functions.

Content [Hide]

- 1 PVC film for the pool: characteristics of waterproofing material

- 2 Varieties of PVC pool trim materials

- 3 Advantages and disadvantages of a pool liner

- 4 How to choose the right PVC film for swimming pools

- 5 Popular manufacturers and prices of PVC films for the pool

- 6 How to make a pool from a film: the main stages of work

PVC film for the pool: characteristics of waterproofing material

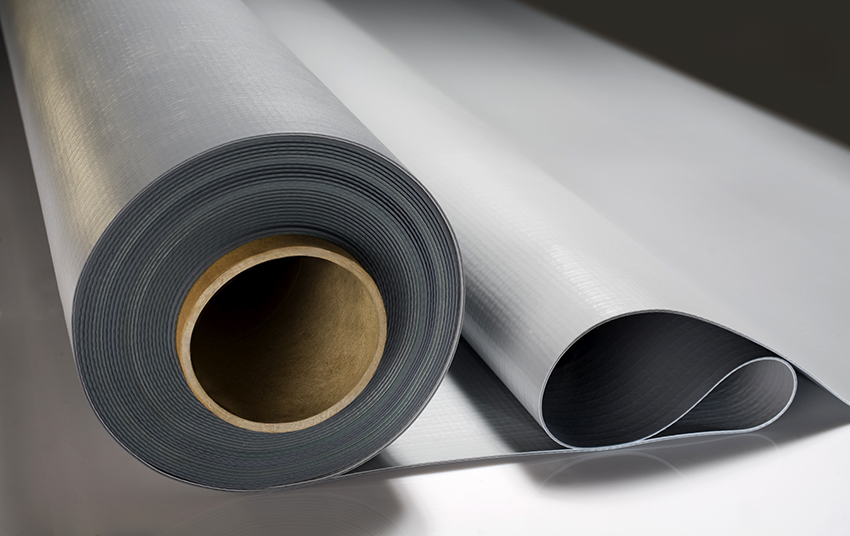

The modern coating, which is attached to the walls of the tank, is a polyvinyl chloride film. It has another name - liner. The film is made of dense PVC, between the homogeneous layers of which a reinforcing layer in the form of polyester fiber is laid. During the manufacture of the liner, special stabilizers are added to the mixture, due to which the final product exhibits increased resistance to ultraviolet radiation.

The pool film is made of polyvinyl chloride, which is treated with a fungicidal and antimicrobial composition

The product is treated with a fungicidal and antimicrobial composition, which protects the material from the effects of pathogenic bacteria, microorganisms, fungi and spores that are in the water. The PVC film intended for swimming pools is certified, which proves the safety of its use. In order for the coating to have a shiny appearance, several layers of acrylic are applied to the product, which also improves the strength characteristics of the product.

Buy a film for the pool, the price of which starts from 300 rubles / m², can be 3.05 wide; 6.1; 9.15; 12.2; 15.2 m. The length of the product is usually 15.2; 30.5; 45.75 and 61.0 m. The material is supplied in rolls.

Varieties of PVC pool trim materials

There are three types of PVC films:

- single layer;

- multilayer;

- butyl rubber.

One-layer blue or light blue PVC film for the pool is presented in a product with a thickness of 0.65-0.8 mm. Such a cover is often used for a collapsible pool and comes with it.Covering the frame base, the material absorbs the pressure from the water that has filled the pool. The outer surface has a rough coating, which creates an anti-slip effect. All components of the material are compactly folded, acquiring a small-sized appearance. Product weight - only 1 kg.

Multilayer PVC film for a pond, the price of which starts from 1500 rubles. for 1 m², it feels like linoleum to the touch. The film is presented in the form of a three-layer material with a thickness of 1.5 mm. The liner consists of two layers of PVC, between which there is a fabric layer with Kevlar fibers. The layers are joined by welding. Such a durable material is used for stationary pools. The outer surface can be glossy or embossed. The liner is characterized by a wide color palette. The product can be monochromatic or with an applied ornament in the form of a mosaic, imitation of natural stone or a photographic image. Such decoration will become a real decoration of the yard.

Collapsible pools are equipped with PVC bowls. For stationary tanks, the material should be cut and welded in place. However, both options can be used if the collapsible tank is large. In this case, the film for the frame pool, included in the kit, is immediately mounted, and then the surface is covered with a liner bag made of reinforced canvas, which is welded and attached with a bandage tape around the perimeter of the structure.

The most durable, wear-resistant and reliable is a two-layer butyl rubber membrane without reinforcement. The material exhibits increased resistance to mechanical stress and sudden temperature changes. The liner is able to withstand high and low temperatures without compromising the integrity of the structure. The film is characterized by high elasticity, so it does not require much effort when lining the pool. This liner is used for large volumetric tanks.

Advantages and disadvantages of a pool liner

High-quality PVC film has a service life of about 20 years. Due to its elasticity and ability to stretch, the material is quickly and easily applied to the tank frame, clearly following its contours. During the manufacturing process, the film is impregnated with special substances, which makes it resistant to biological and chemical influences. Compared to other finishing materials that are used for finishing the pool, PVC film has the lowest cost.

There is no risk of cracking, chips, which are possible in the case of using ceramic tiles or mosaics. If there is a violation of the integrity of the product, its repair is carried out quickly and inexpensively.

When facing the surface of PVC film, there are no sharp edges, which eliminates the likelihood of injury. Due to the wide variety of material designs, the liner is not only a reliable waterproofing of the pool, but also a real decoration of it.

Helpful advice! A small pool leak can be closed with a liner.

Among the disadvantages of the material are the following:

- the likelihood of scratches and scuffs on the surface of the product;

- laborious process of cleaning the pool;

- impractical for tanks with complex configuration;

- violation of the integrity of the surface when exposed to cutting or piercing elements;

- cannot be used in heaving soils;

- the visibility of the butt seams violates the harmonious integral appearance of the surface;

- liner without acrylic coating does not tolerate low temperatures, which causes bubbles and cracks.

PVC film is elastic and stretches well, thanks to this it perfectly follows the contours of the pool

How to choose the right PVC film for swimming pools

Pond or pool PVC film must meet the following criteria:

- be durable, not wrinkle or crumble;

- be resistant to UV rays, low and high temperatures;

- withstand high pressure without significant deformations and damage to the integrity of the material;

- be resistant to mechanical stress.

When choosing a suitable material, you should pay attention to the thickness, the type of the film and the manufacturer of the product. To optimize material costs and ensure a sufficiently strong, reliable and durable coating, the depth of the pool bowl should be taken into account. If it is within 2 m, the film should be 0.5-0.9 mm thick. It is necessary that in other cases the material is not thinner than 10 mm. For pools with a complex configuration, the liner must be at least 15 mm thick.

Helpful advice! For tanks with a relief shape, it is advisable to buy thick, expensive products in the form of bubble wrap for pools. For small structures with a smooth bottom, budget options can be used.

The film has a different design, which affects the performance properties of the material. An ordinary liner has the lowest cost and is characterized by low strength. It is advisable to use it for prefabricated small-sized pools. The liner with reinforcement can withstand significant loads, has high performance and can be used for any tank.

To ensure safety, you should buy a PVC film with an anti-slip coating for the pool, the price of which will exceed other analogues. Liners with acrylic coating have antibacterial protection. The material does not deteriorate. Microorganisms, bacteria and fungi do not multiply on its surface. Such products are characterized by the longest service life, which undoubtedly affects their cost. The price of PVC film starts from 1500 rubles / m².

In order to choose a high-quality material, you should cut along the end of the product. If the structure of the material crumbles and exfoliates, this indicates a poor-quality film that will not last long. A high-quality product has a uniform structure with evenly spaced threads. The fabric should stretch evenly in all directions. The embossed pattern should be uniform.

Popular manufacturers and prices of PVC films for the pool

Today the liner is presented in a wide variety of species. The product is produced in rolls, so the price of pool film is determined per square meter or running meter of the product. The cost of the product depends on the type of material, its thickness, elasticity and manufacturer. The cheapest is a single-layer coating. The price of blue PVC film for the pool is on average 300 rubles / m². A multi-layer product will cost 1500 rubles / m². A liner with a relief anti-slip surface can be bought from 1800 rubles / m².

Depending on the quality and manufacturer, the cost of the film varies from 300 to 1800 rubles. for 1 m²

Among the popular manufacturers who have proven themselves from the best side in the construction market are the following: Elbtal (Germany), AlkorPlan (Belgium), Flagpool (France), Ceplastik (Spain), Lazur (Russia). The German company produces a wide range of high quality PVC coverings with reinforcement, reflective effect and decorative patterns. The cost of the liner starts at 1400 rubles / m².

The Belgian company specializes in coating with imitation of natural stone. You can buy PVC film for the pool from 1500 rubles / m². The French and Spanish manufacturer offers a less varied assortment. Here are mainly monochromatic models in different shades of blue. The cost of the material starts from 1000 rubles / m².The most affordable products are offered by a Russian manufacturer. The average price of a classic blue film will be 650 rubles / m².

How to make a pool from a film: the main stages of work

Today, it is possible, in a short time, with the help of PVC film, to perform the lining of the pool with your own hands cheaply and quickly and very simply. Installation consists of the following steps:

- preparation of the foundation;

- geotextile substrate devices;

- film cutting;

- installation of the liner;

- processing seams.

Before proceeding with the installation of PVC film, you should make sure that the necessary characteristics for the pool bowl are present. The structure must have a flat and smooth surface. It is essential that the edges of the pool walls are strong enough to withstand drilling. The tank must be equipped with adequate protection against groundwater.

To carry out the work, you should have the following materials and tools:

- polyvinyl chloride film;

- nonwoven backing;

- corner or fastening strip;

- a welding hot air gun with the necessary accessories in the form of an iron brush and nozzles;

- silicone roller;

- screws, dowels;

- pressure roller for butt joints;

- elastic glue;

- puncher;

- screwdriver;

- roulette;

- construction knife or scissors.

Do-it-yourself PVC film pool: preparatory stage

Before starting work, carefully clean the pool bowl. This will help reveal all surface defects, which should be perfectly flat. If the walls are lined with bricks, they should be pre-plastered and then sanded. If the surface is concrete, it will have to be putty. In case of serious damage to the bottom surface, it is recommended to fill in the self-leveling screed. Particular attention should be paid to the sides and corners. In these places, it is necessary to ensure maximum adhesion of the solution to the base.

All pool fixings must be flush with the surface and fitted with sealing flanges to ensure a tight connection. Flanges are selected from stainless steel or plastic with chlorine resistant rubber gasket. Next, remove all debris from the pool.

Before proceeding with the installation of the film, it is necessary to qualitatively clean the pool bowl

Helpful advice! If an old building is being reconstructed, where the waterproofing is broken, the installation of PVC film can be carried out directly on the previously laid ceramic tiles.

At this stage, a diagram of fastening the fragments of the substrate and the installation of fastening strips is performed. There is no standard version, since all pools differ in configuration and linear parameters. However, one recommendation should be followed: the strips are placed in such a way as to ensure the minimum number of butt joints.

The layout of fasteners for geotextiles (and accordingly for films) is selected individually, based on the geometry of the pool and the number of strips of facing material. The liner is overlapped with an allowance of 5-10 cm at the bottom of the pool, 4-5 cm - on the walls of the structure and 15 cm - in the corners of the structure.

Creation of a reliable thermal insulation layer in the form of a geotextile substrate

During operation, the pool film, which can be bought at any hardware store, will be exposed to significant loads, as a result of which its service life can be significantly reduced. To protect the liner from damage and at the same time to create a sealing layer on the entire surface of the pool, a geotextile substrate is installed. The material will help to reduce heat loss through the bottom and walls of the pool, which will help the water in the tank to cool more slowly.

To fix the geotextile, a metal tape is used, represented by a plastic-coated fixing strip. It is to it that the PVC film will subsequently be welded. Therefore, it is imperative not to mix up the top and bottom of the tape. The length of the product should be 2 m, width - 8 cm, thickness - 2 mm. The foil is attached to the inner surface of the pool using screws that are screwed into pre-installed plastic dowels. The distance between the fasteners should be 10-12 mm, which will ensure reliable fixation of the liner to the surface of the pool bowl throughout its entire area.

If the structure has rounded sections, triangular cuts are made in the metal strip in several places to ensure a secure adhesion of the strip to the surface. If the pool is equipped with steps, it is better to use corners on their edges, rather than stripes. With their help, it is possible to fasten film segments with a stretch, which will reduce the number of points of attachment of the material to concrete. In some cases, the tape can be fixed to the bottom. This will prevent the bottom sheets from moving and wrinkling on the liner.

Related article:

Sand filter for the pool: to keep the water always clean

Types and types of devices, principle of operation, operation and maintenance of filters. Installation of equipment. Self-made filter.

According to the selected scheme, holes are drilled in the concrete and dowels are hammered. Further, fragments of geotextiles are laid out over the entire area, starting from the walls of the pool. The strips should fit snugly together without creating gaps or folds. On the reverse side of the material, a special adhesive for PVC film for the pool is dotted, which will prevent the displacement of individual elements. At the bottom of the pool, the strips are laid loosely.

Important! If the pool contains embedded parts in the substrate, it is necessary to make the appropriate holes.

The final stage is the installation of metal strips and their reliable fixation with screws. To protect the geotextile from melting when welding the film to the plastic fastener, the joints should be covered with self-adhesive foil.

Do-it-yourself PVC film finishing

Before laying PVC film, the price of which depends on the type of product, cutting should be performed, which is an important and crucial stage. Here it must be borne in mind that when the bowl is filled with water, the liner will stretch. Therefore, the film fragments overlap by 5-8 mm, which depends on the thickness of the product. The strips should fit freely on the surface without undue tension. It is required that the overlap for corner joints is at least 12 mm.

The work of laying the material starts from the bottom of the pool. The quality of all other stages will depend on the accuracy of the installation. Decorating the walls of the pool from the film with your own hands is done from the bottom up. Fragments of the liner are leveled using a plumb line.

Helpful advice! Work on finishing the pool with PVC film should be started in the hot season. The material becomes more elastic at high ambient temperatures, which makes it easy to install on the walls of the tank bowl.

Laying the liner is a complex undertaking that requires special attention and accuracy in the execution of actions, the price of finishing the pool with PVC film starts at 600 rubles / m².

After the installation has been completed, the defect cannot be easily eliminated. It will be necessary to change the whole piece. Adjacent strips are laid immediately, which should be leveled and tackled in one of the following ways. If a thin liner is used, point connections can be made using a solvent. It will melt the material at the contact points and glue it securely.You can use a construction hair dryer to heat the film in certain places, and then fix it.

At the next stage, the fragments of the film are welded. Sections of joints should be warmed up with a hairdryer using the necessary nozzle (depending on the place of installation of the material). Hot air, the temperature of which is controlled, melts the seams. By pressing adjacent elements to each other using a silicone roller, after the material has cooled down, they can be securely sealed. When performing this stage, the following rule should be taken into account: the lower the ambient temperature, the hotter the air must be. In addition, when soldering film fragments together, not as hot air is required as when soldering the liner to the corners or fastening tapes.

Helpful advice! The nozzle of the construction hair dryer should be periodically cleaned from the formed carbon deposits using a special metal brush.

After lining the bottom, you can start finishing the walls of the pool. Sheets are arranged with the required allowance. The fragments are immediately soldered to the fastening tape around the entire perimeter of the pool. Then, the transition joint is joined between the vertical wall and the bottom of the structure. Finally, the fragments are welded in the corners.

The final stage of work in finishing the pool with a liner

After completing the installation of the pool finishing material and completing all welding work, carefully inspect each seam. If defects are found, they should be corrected immediately. After a thorough check, you can proceed to sealing the butt joints. For this, a special sealant is used in the form of a liquid mixture. The substance should stay in the open air for 30 minutes until a plastic-like state is formed. The sealant covers the entire seam surface. It should be applied to vertical stripes from bottom to top, thereby creating an additional sealing layer.

Helpful advice! The joint sealant can be matched to the liner.

After the sealant has completely hardened, which will happen in 30-45 minutes, the pool is gradually filled with hot water having a temperature of 40 ° C. Immediately, you should dial no more than 30 cm. This contributes to a good tension of the vertical film strips. At this time, holes are made, and flanges are installed on the embedded parts. Next, decorative elements are mounted, after which the pool is filled to the top with water.

Today, the selection of pool cladding materials is quite extensive. However, PVC sheeting is the most popular option. This is due to the affordable cost, environmental friendliness, high performance, ease of installation and unpretentious maintenance. For the coating to please the eye for many years, it is important to choose a quality, certified product from a reputable manufacturer.