The most important conditions for the proper functioning and efficient operation of the heating system are its correct installation and distribution. Today, many schemes are available that allow you to implement any heating project in accordance with the specifics and layout of the house. The maximum effective return of the circuits can be provided by the heating collectors, which this article is devoted to.

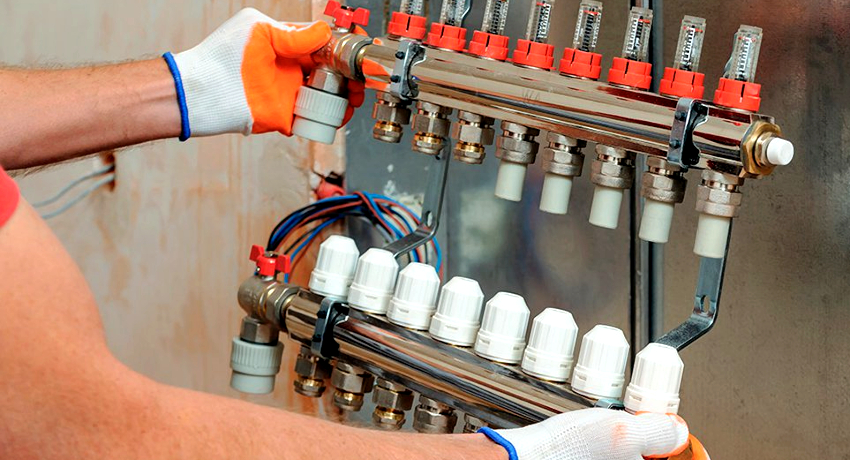

The distribution manifold can be used to regulate the temperature, pressure and volume of the heating medium

Content [Hide]

- 1 What is a collector heating system

- 2 The principle of operation of the heating manifold

- 3 Advantages and disadvantages of a distribution manifold for a heating system

- 4 Collectors for heating: types of devices

- 5 Flat or vacuum solar collectors for home heating

- 6 Features of the manifold manifold for water

- 7 Materials for the production of manifold manifolds for heating

- 8 Basic recommendations for choosing a heating manifold

- 9 Selecting the installation location for the heating manifold

- 10 Popular manufacturers of heating system collectors

- 11 What to make a heating manifold with your own hands: design options

What is a collector heating system

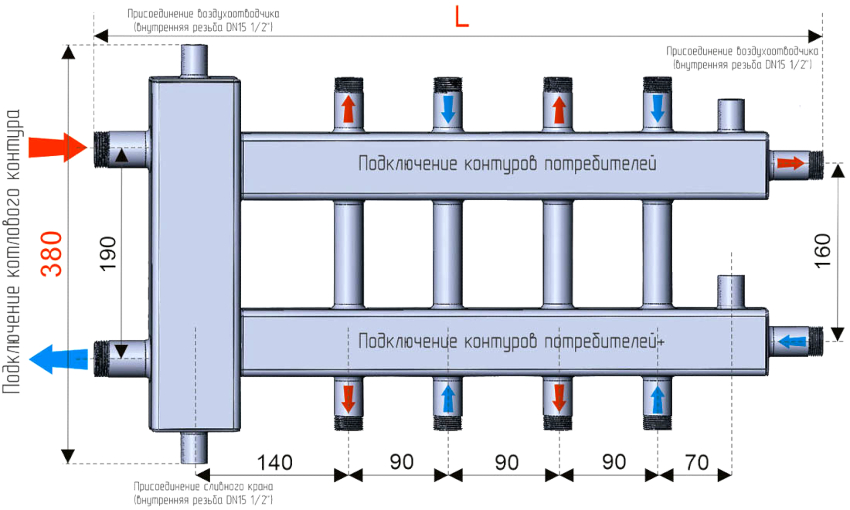

The heating manifold is represented by a volumetric comb, which consists of a supply element that distributes the coolant heated in the boiler for supply to the radiators, and a return part that returns the cooled coolant to the heat generator. The last component of the assembly ensures uniform and smooth heating of each element in the system.

Various heating devices are connected to the distribution manifold in the form of convectors, radiators, underfloor heating systems

With the help of the manifold manifold, the temperature, pressure and volume of the coolant can be regulated, which allows you to control the supply of heat to each separate room of the house. Due to its integration, various heating devices are connected to the distribution manifold in the form of convectors, radiators, underfloor heating systems or panel heating. The dimensions of the device are determined by the number of circuits represented by pipes that are connected to it. The maximum number of elements can be up to 12 pieces. In this case, the collector consists of two combs, each of which has 6 circuits.

Useful advice! Some manufacturers make manifolds with a large number of dies or a one-off piece that is custom made.

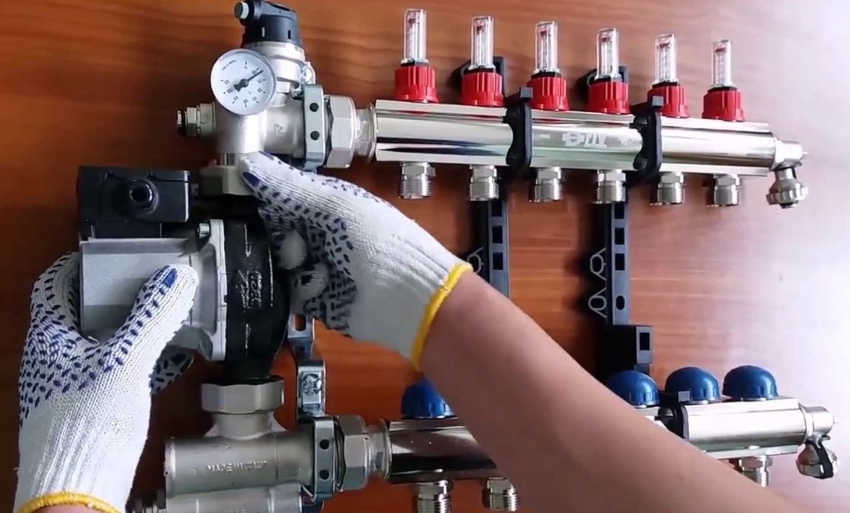

Each outlet of the device has an outlet valve and an adjustment or shut-off valve.The presence of these elements allows inside each circuit to adjust the pressure and, if necessary, disconnect the branches for repair.

To increase the performance of the system and to be able to control all technological processes in each separate room, the comb body can be used as a platform for installing flow meters, heat meters, drain or air vent valves.

The principle of operation of the heating manifold

Consider the principle of operation of the manifold distribution unit. The heated coolant from the heating generator enters the supply manifold. In the intermediate unit, the fluid velocity decreases, which is due to the increased internal diameter of the device. Thus, the coolant is distributed evenly in the system.

Important! The inner diameter of the distribution unit is determined by a calculation method, ensuring the speed of the coolant in the system is not more than 0.7 m / s.

Further, the liquid through the connecting pipes with a smaller section moves into separately located circuits and is diverted to the heating radiators or to the floor heating grids. This distribution contributes to the heating of each element, where the heat carrier of the same temperature enters.

Having reached the radiator, the coolant gives off the heat received from the heating generator. Further, the liquid is directed in the opposite direction along a different circuit to the distribution block. There the coolant is diverted to the return manifold, from which it is directed to the heat generator.

Installing a heating manifold is the most efficient and reliable option for a frequent home. However, the arrangement of this unit will be more expensive than the installation of a traditional tee system.

Advantages and disadvantages of a distribution manifold for a heating system

The collector version of the heating system has its positive and negative sides. Such a comb is able to ensure uniform heat distribution and maintain the required coolant temperature in all heating devices. At the same time, it is possible to organize a decrease in temperature if necessary.

By adjusting the heating collector, you can not only control the temperature, but also completely cut off any branch, which prevents idle heat transfer. This is especially useful for a large home where some rooms are not used for living. The system is controlled from the heating manifold cabinet.

The distribution manifold assembly is characterized by ease of installation and repair. In the event of a breakdown of one of the system parts, it will be enough to cut off the damaged branch by means of a regulating device. The comb for heating has an attractive appearance, which allows you to place the device in any convenient place.

The disadvantages of the hydrocollector include the high cost of the structure, which is associated with the high cost of the material from which the product is made. Quality fittings are also quite expensive. However, the cost of installation work is minimized due to the simplicity of the design.

A fully and efficiently heating system will work only in combination with a circulation pump, the operation of which will entail additional costs for electricity.

The comb device assumes a large number of branches for each heating device, for which a separate pipe is installed. This increases the labor intensity of installation and the overall cost of the entire system.

Collectors for heating: types of devices

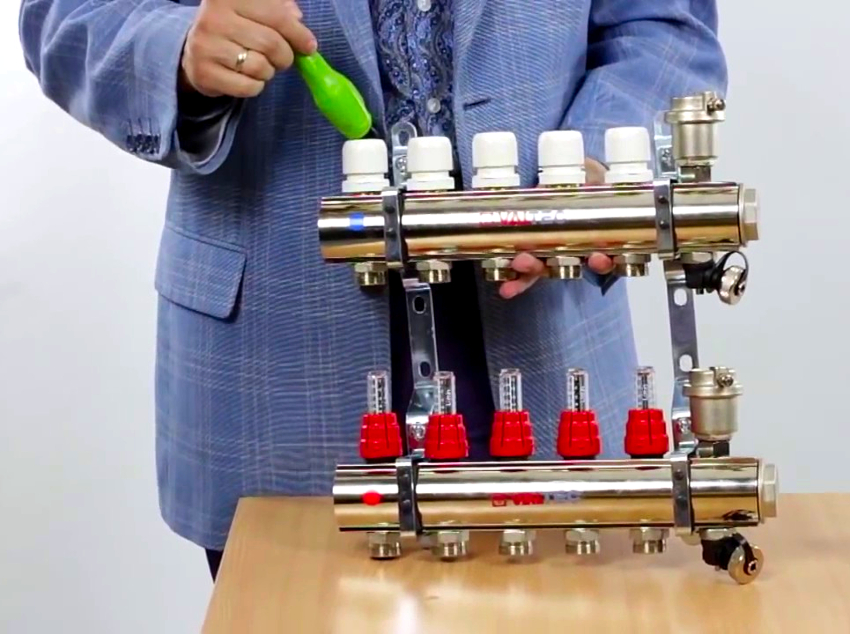

There is no standard configuration for the heating manifold. The device can be made in any modification, which allows it to adapt to a variety of heating systems with different types of devices and the number of circuits. The comb has from 2 to 12 circuits, the price of the heating collector depends on this indicator. During operation, the number of involved branches may vary.

The device can be made in any modification, which allows it to adapt to a variety of heating systems

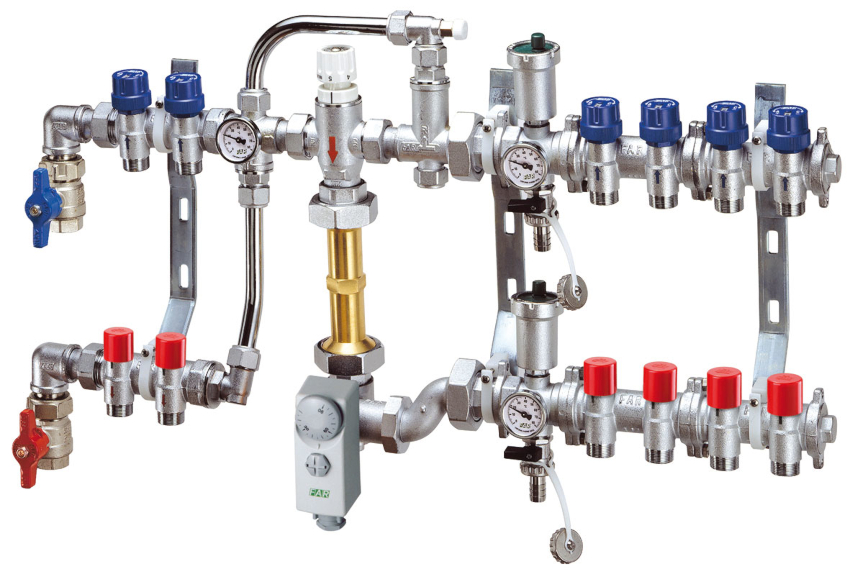

According to the technical characteristics, the heating distribution units can be divided into the following types of collectors: solar, with a hydraulic arrow and radiator. By the number of system elements, simple and advanced models are distinguished. The first option is not equipped with additional devices to control the operation of the device and to adjust it. It is represented by a simple comb with several branches, each of which can be turned off. In such a system, control over the temperature and volume of the coolant is not expected.

The improved products are equipped with pressure and temperature regulators, pressure sensors, control units for supplying water, thermostats for automatic pressure adjustment, electronic mixers and valves for regulating the supply of cold and hot water, air vents to release air bubbles from the pipes.

Important! The set of the manifold assembly may vary depending on specific system requirements, which affects the functionality and cost of the installation.

Flat or vacuum solar collectors for home heating

Solar collectors differ from traditional heating installations in their design. They consist of panels designed to convert solar energy into thermal energy. The absorber of a flat product is represented by an aluminum plate, in which a copper coil is located. A natural circulation of the coolant takes place along it, suggesting the displacement of the warm flow upward and its direction to the heating devices.

Solar collectors are placed on the roof of the house, where the maximum level of solar radiation is concentrated.

It is advisable to use such systems in the southern regions. The devices are used to obtain hot water, which can be used for centralized hot water supply or as a heat carrier for heating systems.

The vacuum manifold for heating consists of light-absorbing bulbs, in which the tubes are located, where the coolant moves. This system is highly efficient. It can be installed even in regions with low solar activity.

Solar collectors are placed on the roof of the house, where the maximum level of solar radiation is concentrated. Such systems do not take up much space and do not interfere with anyone.

The circulation of the coolant can be carried out in a natural or forced way. In the first case, the heated water expands and rises, and the cooled stream is displaced into the heating tank. Forced circulation requires a pump. Using mixers, you can change the movement of water in the system.

The vacuum manifold for heating consists of light-absorbing bulbs, in which the tubes are located, where the coolant moves

Solar collectors provide the house with hot water in the summer. In the spring-autumn period, such a system can be used as an alternative option for heating, which allows saving gas or electricity consumption, thereby reducing the cost of paying for consumed resources.

Radiator water distribution manifold

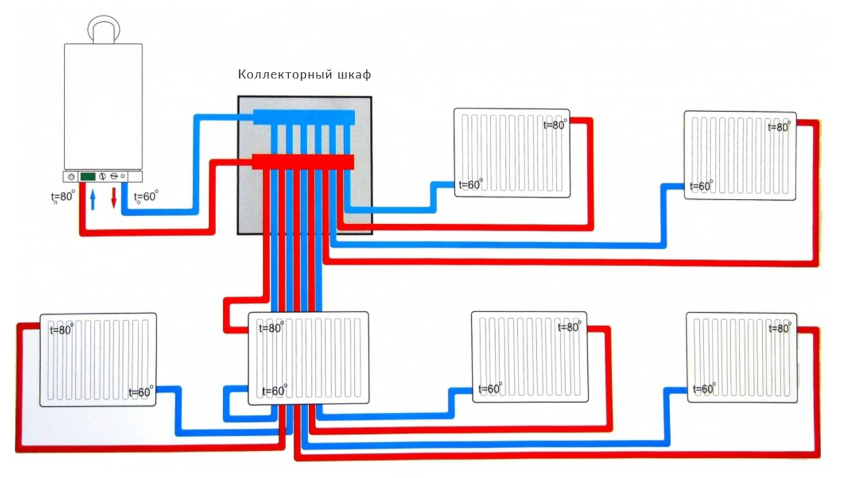

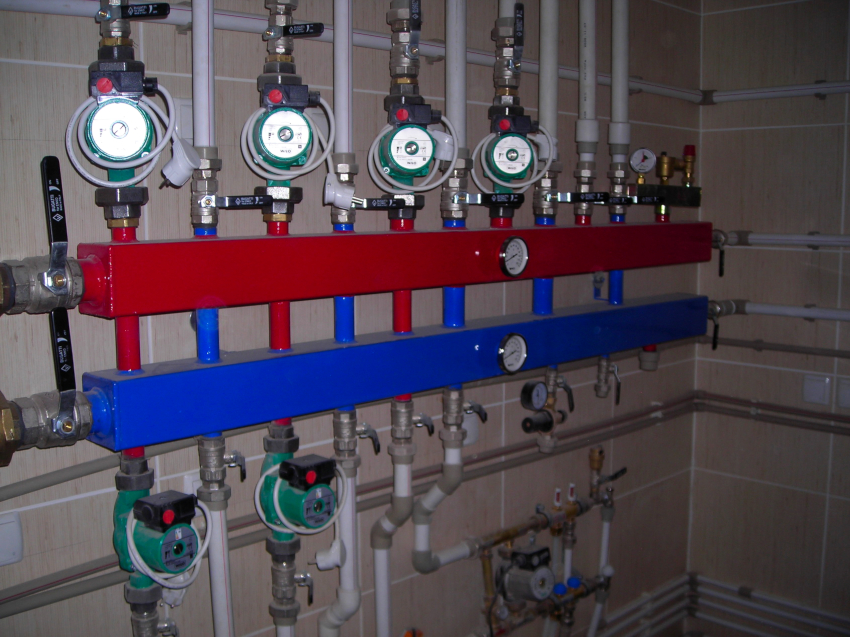

The collector for radiator heating is the most demanded, since almost every house has batteries.The distribution unit is represented by two interconnected manifolds, where the first supplies the coolant to the heating devices, and the second removes the liquid back to the heater.

These manifolds can be diagonal, top or bottom connected. The latter option is the most common, since all the wiring is hidden under the surface of the floor or baseboard, which is not striking.

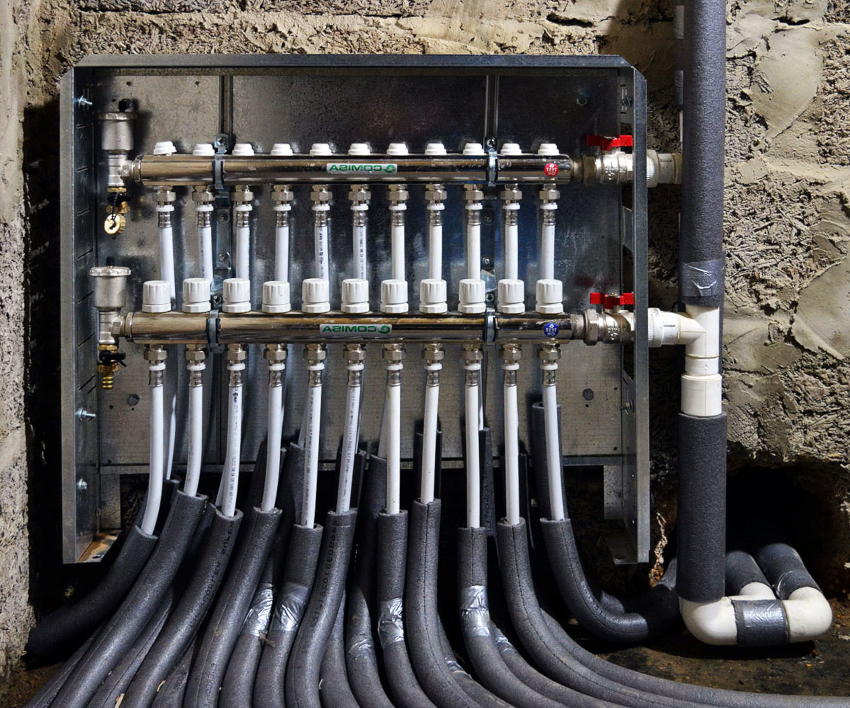

The radiator heating manifold is installed on each floor of the house in such a place that will ensure the equal length of the supply branches to each heating device. The unit can be arranged in a niche or mounted in a special cabinet on the wall. The number of branches depends on the number of rooms that are looped on one comb. The number of collector groups should be based on the length of the circuits. One node is allocated 120 m of the pipeline.

Important! If it is impossible to achieve equality of the connected rings to the collector, each branch must be supplemented with a circulation pump.

All branches connected to the node are independent circuits equipped with their own shut-off valves and automation. Shut-off and control valves are installed here, which are necessary to select the optimal coolant supply.

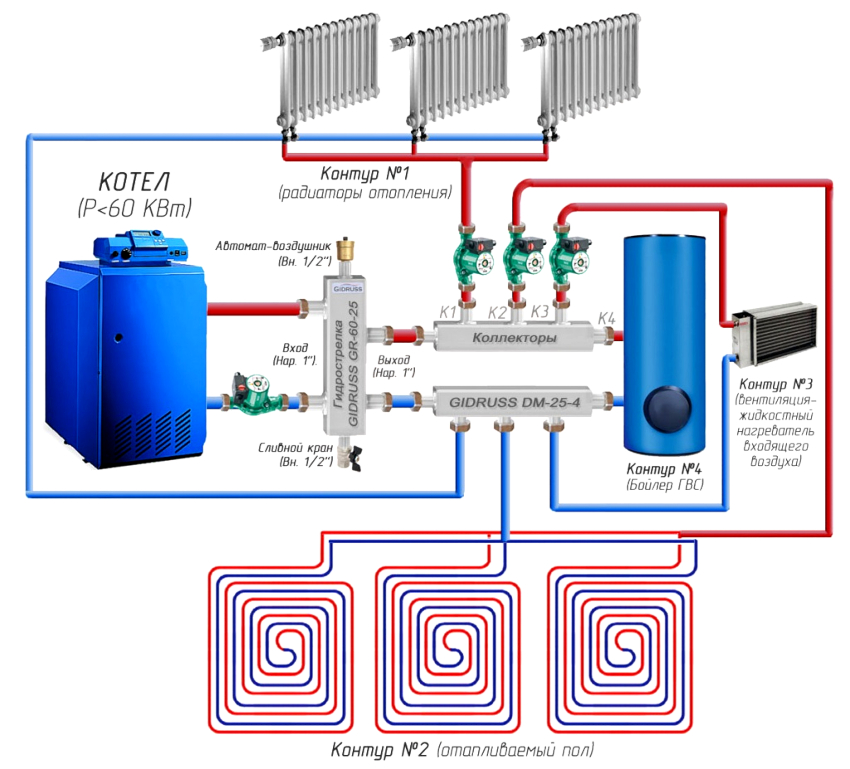

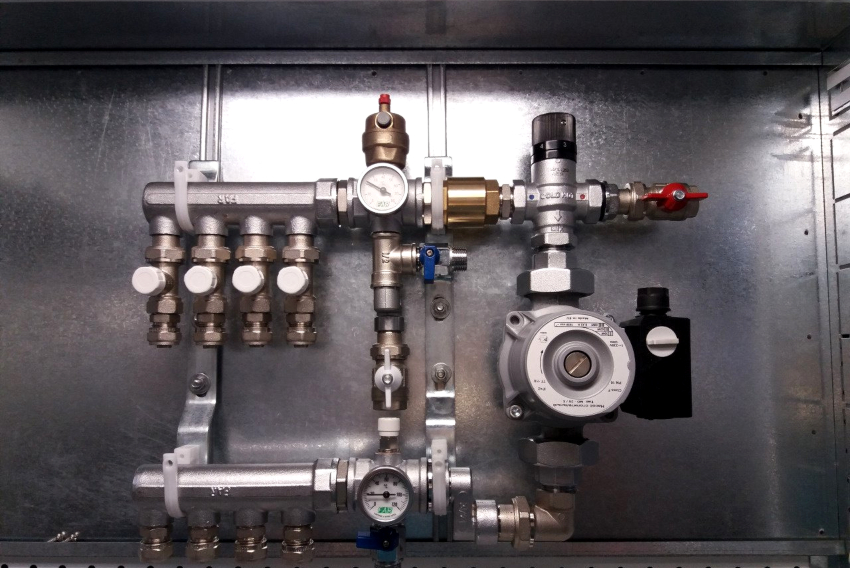

Characteristic of the distribution manifold with a hydraulic arrow

When arranging a distribution heating system with a large number of circuits, it is advisable to use collectors with a hydraulic arrow, which is needed to balance the entire unit. This is achieved by separating the boiler hydraulic circuit from the secondary circuit. A heater is connected to a unit with a thermohydraulic distributor on one side, and a floor heating system or radiator heating on the other.

The hydraulic arrow is represented by a vertical hollow tube equipped with elliptical end caps. It helps to equalize temperature and pressure, which guarantees an optimal temperature between flow and return.

Efficient operation of the heating system with a hydraulic arrow is possible if each circuit has its own circulation pump

Such a hydraulic separator allows, if necessary, to mix the flows, to compensate for the flow deficit in the secondary circuit, to maintain a constant volume of water. This is achieved through the secondary circulation of some of the coolant. The hydraulic arrow eliminates the likelihood of sudden temperature changes in the pipes, which negatively affects the period of operation of the system.

Important! Optimal and efficient operation of the heating system with a hydraulic arrow is possible if each circuit has its own circulation pump.

Units with a hydraulic arrow are intended only for complex heating systems in large facilities. This is the most suitable option for a 4-circuit heating manifold. In this case, it is possible to organize independent units with different operating parameters, such as hot water supply, radiator heating, underfloor heating, pool water heating. Each of the 4 circuits on the heating manifold can differ in the internal diameter, the type of radiators installed or the heating option.

Related article:

DIY heating in a private house from polypropylene pipes

Classification, price and technical characteristics of PP pipes. Features of schemes and rules for installing water heating from polypropylene.

If the collectors for the boiler room are used in the factory, they are supplemented with special branches for air and debris, thereby increasing the efficiency of the entire system.

Features of the manifold manifold for water

To increase the comfort of using hot and cold water, plumbing manifolds with shut-off valves are used. The device provides separation of water into several streams. Due to the fact that the diameter of the inlet exceeds this value for the outlet by 20-40%, there is no decrease in water flow and pressure when several taps are opened simultaneously.

The collector circuit is more convenient and comfortable to use than the traditional one. However, its cost will be several times higher than the price of a conventional system. For example, a Pexay water distribution manifold costs 5-10 thousand rubles.

The manifolds are available in stainless steel, brass, PP or XLPE. Pipes for the water supply system can be fastened using threaded connections, by means of Euro cones, using compression fittings. A combined version is also used, which involves a threaded connection for large diameters and soldering or compression fittings for small ones.

Distribution manifolds for water supply can be equipped with 2-6 outlets. The product has two docking fittings that correspond to the diameter of the water supply pipe. They are also used to connect several elements into a composite block without the use of additional adapters.

Important! The collector water supply system allows you to turn off one of the water consumers in order to carry out repair and restoration work, without affecting the rest.

When choosing a material for the manufacture of a collector, the type of supply pipe should be taken into account. It is better if they are made of the same material. It should be borne in mind here that polyethylene products are connected with compression fittings, and polypropylene products - by soldering. A filter, meter and non-return valve should be installed in front of the collector.

Useful advice! To facilitate installation and ensure a reliable connection of elements, it is necessary that the manifold for water supply, pipes and fittings are made by the same manufacturer.

Materials for the production of manifold manifolds for heating

Various materials can be used for the manufacture of a heating manifold, but they must be distinguished by increased strength and high performance.

Currently, steel, polymer and brass manifolds are very popular. Steel can be used for the production of both central and local elements. It does not deform under the influence of high temperatures and high pressure, special alloys are not subject to corrosion, which increases their service life. The main disadvantage of steel elements is the high price of heating collectors.

Brass devices are in no less demand. Due to its high pressure and temperature resistance, the material is ideal for local and centralized sites. In terms of its technical and operational characteristics, it is similar in stainless steel. Brass collectors are characterized by a high cost, exceeding the price of steel counterparts.

Polymer products have a more limited range of applications. Plastic collectors are not able to withstand the high temperature in the central unit, therefore they can only be used for local options, where the temperature of the coolant will be lower. The products are characterized by low weight, ease of installation and long service life. The main advantage of the products is their low cost.

Important! Polymer pipes should not be used to connect the underfloor heating system.

Basic recommendations for choosing a heating manifold

Before purchasing a heating manifold, you should study the technical characteristics of the devices, which include the throughput of the system, the maximum operating pressure of the product, the possibility of connecting additional circuits, the availability of equipment for control and automation, the amount of electricity consumed. These parameters are indicated in the passport for the device.

Important! The pressure in the distribution system will depend on the location of the manifold.

When choosing a collector for radiator heating or a floor heating system, it should be borne in mind that a high-quality and durable device will have a high cost. This is due to the fact that durable expensive materials are used for its manufacture, and the production technology is carried out on the latest, improved equipment. The quality assurance is the acquisition of a collector from a well-known manufacturer with a worldwide reputation.

A simple system can be installed independently, and it is better to entrust the installation of an improved type heating collector to a specialist. This is especially true for a distribution unit for 3-4 circuits. The collector system will be able to fully function if there are taps, plugs and a circulation pump for each circuit, which will increase the cost of the system.

A simple system can be installed independently, and it is better to entrust the installation of an improved type heating collector to a specialist

Selecting the installation location for the heating manifold

Before connecting the heating manifold, check the installation site for any interference. Such a distribution heating system assumes floor-by-floor installation of pipelines. An independent heating circuit with autonomous control is organized for each floor. This takes into account the parameters of the subsystem they serve.

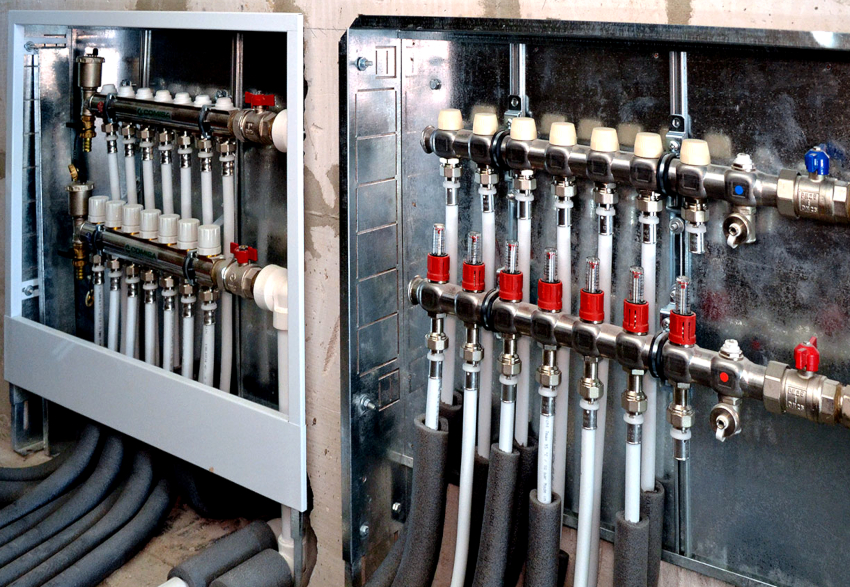

The unit is installed in a separate niche just above the floor. The location of the device is selected at the design stage of the house. If this was not provided, then the collector can be placed anywhere by hiding it in a cabinet. The main requirement is the optimal humidity of the room where the heating distribution unit will be located. A pantry, corridor or dressing room is suitable for this purpose.

A cabinet for a distribution unit can be made independently or purchased ready-made from a manufacturer that produces shut-off valves. The design is represented by a metal box with doors. Holes are made in the end walls of the product for laying the system pipelines.

If aesthetic requirements are not imposed on the place of installation of the collector, then it can be fixed to the wall in an open form using special clamps.

Popular manufacturers of heating system collectors

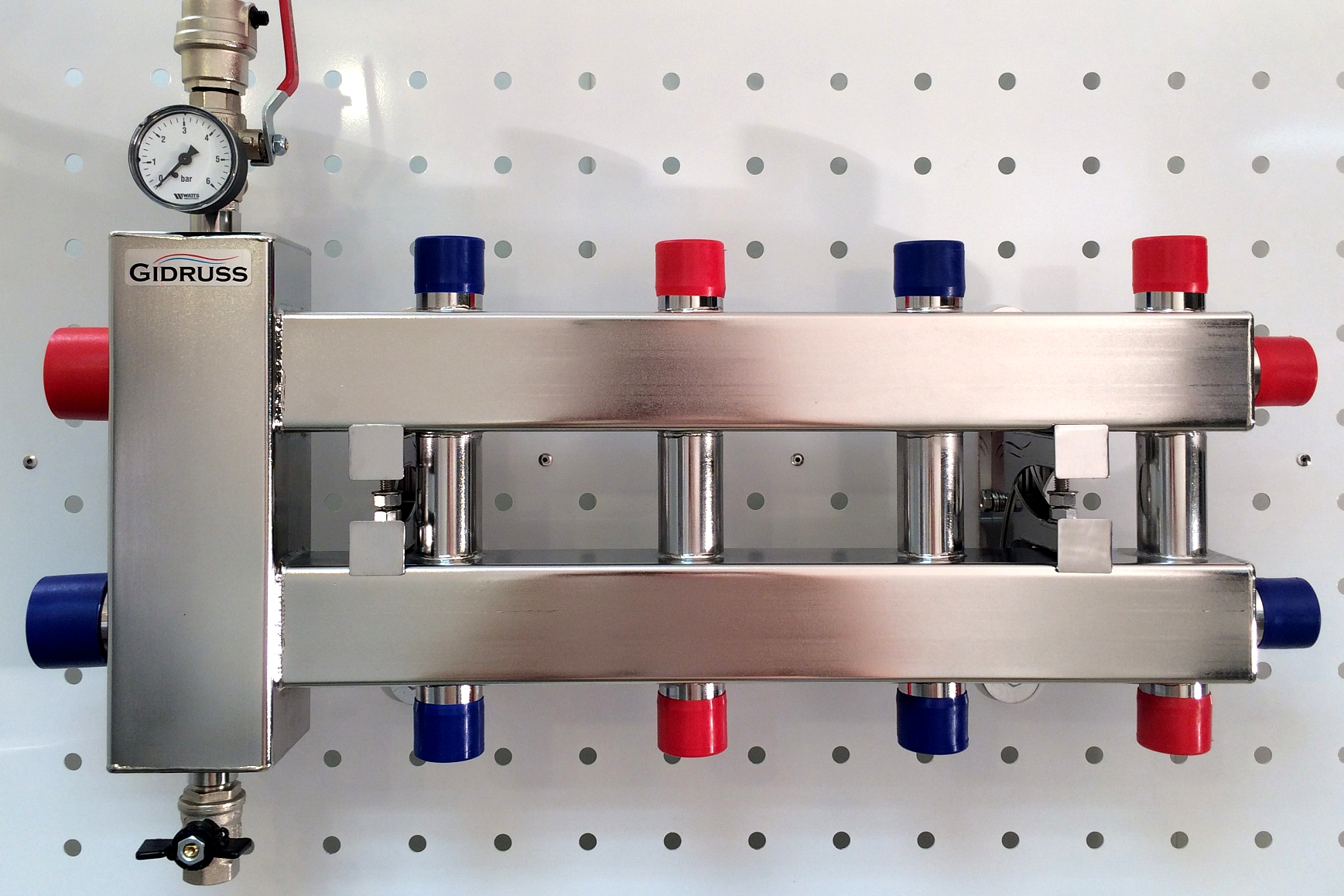

Popular manufacturers of high-quality collectors are Rehau and Oventrop, which give the maximum warranty period for their products. Consumers note the high quality of products, reliability, ease of installation and long service life.

Oventrop specializes in the production of universal collector models that are ideal for radial heating, underfloor heating and water systems. High quality stainless steel is used for the manufacture of products. The collectors are capable of withstanding temperatures up to 120 ° C. The cost of products varies from 2.5 to 28 thousand rubles.

Combs for radial heating made of stainless steel are most in demand among consumers. These manifolds are designed for a pressure of 10 bar and a system temperature of up to 100 ° C. You can buy the product for 1.7 thousand rubles.rub. Distribution manifolds for underfloor heating made of tool steel are produced with valve additions, with the help of which the operation of the system is regulated. The manifolds are designed for pressures of 6 bar and temperatures up to 70 ° C. You can buy a double-circuit product for 3.5 thousand rubles.

Rehau distribution manifolds have a more attractive appearance, which makes it possible to mount them on the wall in an open way. Products are made of stainless steel and brass. The company produces improved models complete with flow meters, taps, valves and a pump. The device can be purchased for 1.5-32 thousand rubles, which depends on the number of product contours.

The HKV underfloor heating comb, made of brass, is very popular. The manifold is designed for temperatures up to 80 ° C and operating pressures up to 6 bar. The cost of a double-circuit product is 6.5 thousand rubles.

The Rehau HLV distribution manifold can be used for radial heating. The brass product can withstand a temperature of 80 ° C and a pressure of 8 bar. The price of the model is 4 thousand rubles.

The domestic manufacturer Sever deserves attention, offering high-quality hydraulic manifolds at an affordable cost, which ranges from 2.5 to 20 thousand rubles. Products are made primarily of steel. Pexay collectors for heating are characterized by an ideal ratio of price and quality, the average price of which is 5-12 thousand rubles.

What to make a heating manifold with your own hands: design options

Before proceeding with the independent manufacture of the device, it is required to calculate the heating manifold with the determination of the number of circuits, prepare the necessary materials and tools.

For the production of a polypropylene heating manifold, you will need a pipe with a diameter of 32 mm and tees 32x32x16 mm

For a heating system, the pipe diameter should be 12.7 mm. The collector is made with a diameter of 25-40 mm, which is determined by the type of boiler. The distance between the outlets is 15 mm, and between the supply and return outlet is 25 cm.

For the production of a polypropylene heating manifold, you will need a pipe with a diameter of 32 mm and tees 32x32x16 mm. A tee is installed on one side of the pipeline, to which an air outlet and a water drain valve are connected. On the other side of it, a valve and a pipe, inlet or outlet, are mounted.

The unit can also be assembled from brass fittings and tees, having previously completed the heating manifold diagram with the required number of circuits. The elements are attached to each other by means of cushioning material in the form of linen tow or a liquid retainer. It is better to install complex collector systems with the help of a profile pipe and shut-off and control valves. In this case, pipes of different diameters are used, which are connected by welding.

The guarantee of the reliability and efficient operation of the heating system is a correctly selected and correctly assembled manifold unit. Due to the fact that it can consist of several circuits, it is possible to control each group of heating devices individually, which makes the operation of the heating system especially convenient and comfortable.