Thanks to the advent of modern flexible water hoses, the connection of household appliances that require a central water supply has been greatly simplified. Now there is no need to carry out welding work in order to grow the pipe - it is enough to install a flexible hose. Bellows water liner is considered the most modern and safe option. Quality materials used in the manufacture guarantee a long service life in different conditions.

Content [Hide]

- 1 Technical characteristics of the main types of flexible water connections: which is better

- 2 Bellows pipe for water: main characteristics

- 3 Major manufacturers of stainless steel flexible water hose

- 4 How to choose the right flexible hose for water 1/2 and other diameters

- 5 Features of self-installation and maintenance of flexible liners

Technical characteristics of the main types of flexible water connections: which is better

In retail outlets, you can observe a large selection of flexible hoses for supplying water from different manufacturers, which differ not only in price, model or functional purpose, but also in the quality of the materials used, which affect the life of the product.

Important! When choosing flexible hoses, it is necessary to consider the quality of the materials used to make them. The seller must necessarily present documents confirming the compliance of the flexible water pipe with GOST standards, as well as certificates confirming the quality of the products.

A reliable flexible hose should be made of aluminum or stainless steel. The price is influenced not only by the material, but also by the presence of additional options. So, some manufacturers offer hoses equipped with anti-vibration liners, which have a large cross-sectional diameter. This reduces the noise level when water is supplied to the household appliance. To understand which flexible water line is the best, you should familiarize yourself with the technical characteristics of each type.

Rubber hoses. The main advantages of these models are considered to be low cost and the ability to operate under high pressure. The hoses consist of a frame made of strong threads or metal spirals. Rubber is used to cover either the outside or the inside. Main characteristics:

- The maximum pressure level for which the rubber reinforced hoses are designed is no more than 10 bar.

- The temperature of the liquid that will be supplied through the hose must be within the range from -50 to +120 ° C.

Briefly about PVC sleeves and reinforced hoses: basic parameters

Hoses made of polyvinyl chloride (so called PVC) are highly flexible. Additional rigidity to PVC sleeves is given by a reinforcing spiral placed inside the product. Main advantages:

- light weight;

- resistance to chemicals;

- smooth inner and ribbed outer surfaces for ease of installation;

- not afraid of direct sunlight;

- the working pressure for which the hoses are designed is 15 bar.

The main disadvantage of installing PVC hoses is a small temperature range at which it is permissible to use the device - from -20 to +60 ° C, which does not allow using this type of flexible connection for hot water.

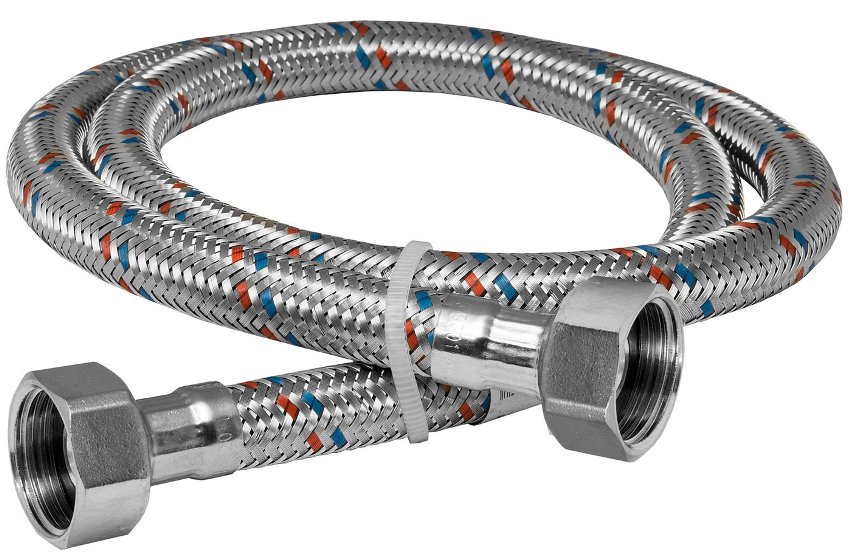

Reinforced liner, which is a soft braided hose, is made of aluminum, stainless steel or galvanized steel. The most popular domestic manufacturer that produces flexible water connections is Elka, which offers products in a nut-nut design with a 1/2 inch diameter.

Sometimes nylon is used instead of a metal braid, but usually these hoses are not used in a domestic environment. Technical parameters of various options for reinforced flexible hoses are presented in the table:

| Reinforced liner type | Parameter | ||

| Service life, years | Maximum allowable pressure, bar | Maximum temperature at which operation is possible, ˚С | |

| Galvanized steel and aluminum | No more than three | 5 | +80 |

| Stainless steel | To 10 | 10 | +95 |

| Nylon | 15 and more | Up to 20 | +110 and above |

Bellows water line: Main characteristics

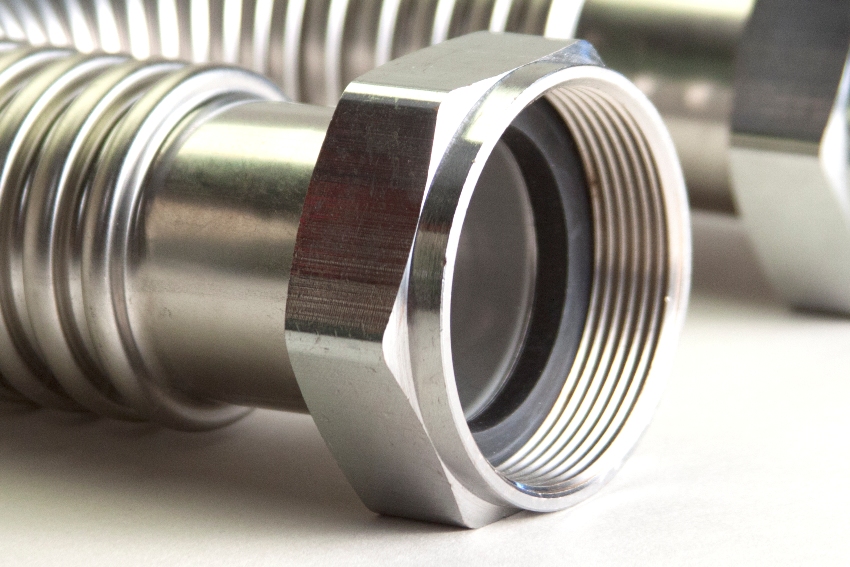

The stainless steel bellows hose for water is a corrugated hose, for the production of which steel with the AISI 304 marking is used. The hoses are welded or seamless, but the wall thickness is usually standard and is 0.3 mm. In a complete set, the hose comes with connectors, the so-called fittings: this is either a union nut, or a fitting, coated with nickel or chrome. They are made from materials such as:

- brass;

- steel;

- bronze.

Hoses that use brass connectors are highly resistant to corrosion, and the price of the product is quite reasonable. The service life is usually 5 years, because brass nuts are not welded, but are attached to the ends of the hose by soldering. Under the influence of high temperatures, the soldered seam breaks down faster.

Connectors made of stainless steel are considered the best option, since they withstand high vibration loads and thermal expansion. However, the price of flexible water pipes with stainless fittings is much higher than the cost of products with brass connectors, although they can be used much longer - up to 10-15 years.

It is not recommended to choose hoses where the fittings are made of carbon steel, which is unstable to rust and corrosion, and constant exposure to humid conditions leads to their rapid oxidation. Usually carbon parts need to be replaced every 2-3 years.

Interesting information! Reliable fixation and high-quality tightness of the joints in the bellows is ensured due to the fact that 2-3 outer corrugated rings pass the rolling process.

In shopping centers, various sizes of flexible hoses for water supply are presented, which differ not only in length, but also in the diameter of the inner section of the nuts. The most popular are flexible water liners 1, 1/2 inches, as well as 2 and 3/4. If a non-standard 3/8 flexible water connection is used, then you need to additionally purchase an adapter before installation. Below is a table of sizes in inches and centimeters:

| Section size, inches | Section size, cm |

| 1/2 | 15 |

| 3/4 | 20 |

| 1 | 25 |

| 1 1/4 | 32 |

| 1 1/2 | 40 |

| 2 | 50 |

| 2 1/2 | 65 |

The main reasons that made flexible bellows-type water connections popular

The reliability and durability of the bellows hose for water is provided mainly by the material used for manufacture. High quality steel, which is used by reliable manufacturers, is durable. The material is resistant to corrosion. Other technical characteristics of 1/2 inch bellows hoses for water (and other sections):

- They tolerate the effects of aggressive acids and other chemical compounds.

- They are characterized by high resistance to changes in both pressure inside the pipeline and temperatures.

- They are characterized by a long service life of 20 years or more.

- They are used in a wide temperature range from - 40 to +250 ° С, which allows installing flexible bellows for heating.

- The working pressure for which the sleeves are designed is 1.5-3 MPa. This indicator depends on the cross-section diameter and wall thickness.

- Includes paronite gaskets or copper or fluorinated polymer seals.

Stainless steel bellows liners are durable, therefore they are not inferior to copper ones, but they are much easier to install

When buying, it is important to take into account that the thickness of the sealing gasket should not be less than 2.5 mm, because during operation it is subjected to heavy loads. It is also necessary to know the main sign that allows you to distinguish a water hose from a gas one. The products have different markings: for water - blue or red, and for gas - yellow.

Each individual hose is complemented by a retaining ring that ensures a more tight fit of the seals and the seam to the water pipe or adapter, which is used when the diameter of the hose does not match the diameter of the pipe. All types of bellows hoses can be divided into 2 main groups depending on the features of use:

- Extended sleeves that are used to supply water to far-away household appliances or plumbing fixtures, for example, a dishwasher, washbasin, shower cabin. The length of the hoses varies from 90 cm to 3.5 m, and the standard equipment of the flexible connection for water is a nipple-nipple, nut-nut or nut-nipple.

- Adapter sleeves. This group includes flexible water connections, the length of which varies from 20 to 100 cm. They are used for direct connection of the consumer to the central water supply.

The durability of the stainless steel water liner depends on compliance with the rules for its installation

Main features and advantages of stainless steel bellows flexible water hose

The bellows connection for the mixer has gained popularity due to the large number of advantages over other models. If only high-quality metal was used in the production, then the hose is characterized by increased resistance to sudden water hammer, as well as to oxygen diffusion, which appears due to the increased pressure within the network.

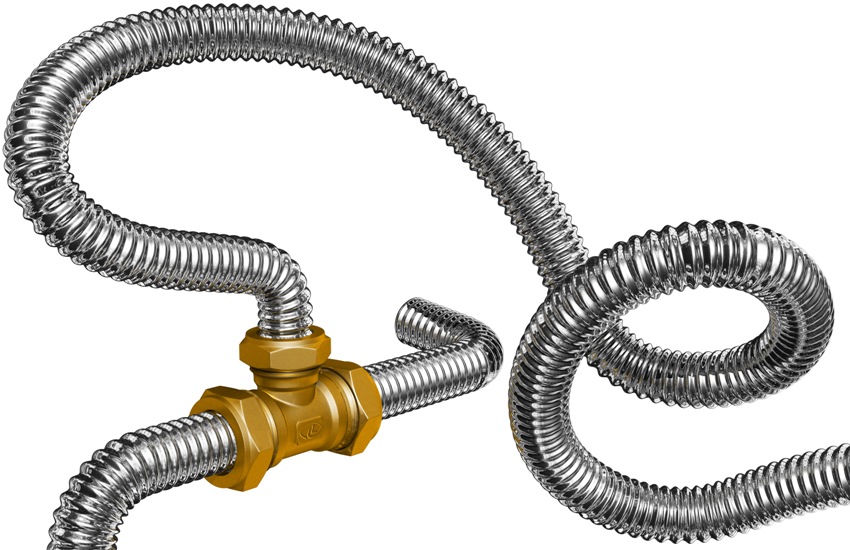

Other advantages are considered to be the high resistance of the device to the effects of fire, the environmental safety of the materials used in production, which makes it possible to operate the hoses in domestic conditions and in any residential premises.Among other product options, the stainless steel bellows pipe is distinguished by increased wear resistance, which ensures a long service life, which is at least 2 times longer than the service life of other types of flexible hoses. Thanks to the corrugated base, the bellows is able to maintain and maintain constant pressure along the entire length of the hose, even in the event of severe kinks.

In addition to the fact that the bellows connection is used to connect water or heating, it is often used when installing air conditioning equipment and fire extinguishing systems. The product can be used as a device that provides steam removal during the operation of industrial enterprises that use oil refined products and toxic chemicals.

Flexible stainless steel hose is presented in two options: hoses with a fixed length and foldable, which can be stretched

It is interesting! The large cross-section of the flexible water line (2 "or 2 1/2) allows the product to be used even in the food industry, due to which the supply of free-flowing substances or special liquids is carried out. In everyday life, such a large diameter is often used to drain water from the washing machine.

Despite the fact that stainless steel bellows flexible water connections have a large number of advantages, the products also have some disadvantages. The main one is considered to be a lower rate of flexibility in comparison with rubber hoses. In some cases, this causes certain difficulties during installation or requires the use of an additional angle adapter. For example, such a situation can be encountered when connecting a small sink, which is located close to the main water pipe, when the installation of a corrugated hose becomes much more difficult.

Many consider the main disadvantage of the bellows liner to be the high price, which is at least 2 times higher than the cost of analogues made from other materials. If we consider that the guaranteed service life of the bellows hose is 2 times higher, then the high cost due to this is easily leveled.

Bellows hoses for water can be used not only for connecting water supply, but also for equipping heating systems. With their help, the radiator is connected to the main heating pipe. This advantage is due to the fact that the products are designed to work with high temperature water, which is unusual for other types of flexible water hoses.

Major manufacturers of stainless steel flexible water hose

The modern market provides a large selection of flexible bellows line for water. You can pick up both European and domestic products. At the same time, the products of Russian factories are more suitable for connecting to classic versions of pipes in apartments. Thus, the flexible water supply "Gigant Aquaprof" produces hoses with an increased inner or outer diameter, which, in comparison with standard versions, have a higher flow capacity. Gigant hoses are stress-resistant and the surface is not subject to mechanical stress. High reliability is additionally provided by the presence of thickened walls.

Related article:

Bellows gas line: the safest way to connect gas equipment

Application features, advantages and disadvantages. Other types of flexible hoses for connecting gas equipment. Safety engineering.

All Gigant Aquaprof hoses are made of high-alloy stainless steel, and the brass union nuts are reinforced with a nickel layer. Flexible hose meets the requirements of GOST 12.2.063.81 and GOST 15763-2005. The main dimensions of the sections of the flexible water supply "Gigant" are 1/2, 3/4, 1.Prices for these products are presented in the table below:

| Section size, inch | Length, cm | Price, rubles |

| 1 | 60 | 475-720 |

| 80 | 540-800 | |

| 100 | 780-1100 | |

| 3/4 | 60 | 230-280 |

| 100 | 240-320 | |

| 150 | 300-420 | |

| 1/2 | 40 | 230 |

| 60 | 250 | |

| 80 | 270 | |

| 100 | 320 | |

| 150 | 410 |

Many plumbers, when carrying out repair or installation work, prefer to use hoses from European manufacturers, among which Italy and Germany are the leaders. Consider the most popular Italian companies that produce bellows.

Indrosapien. Due to the high quality of finished products and a large assortment, the manufacturer is popular with buyers. All products of the company have passed certification in Russia and are recommended for installation in a domestic environment. For the manufacture of products, stainless steel AISI 303 is used. Flexible connection for water, nut-union is made with an external thread. The fittings are made of nickel-plated brass. They are secured by industrial welding.

Bellows Gigant is characterized by resistance to stress, and its surface does not lend itself to mechanical stress

Emiflex. Another Italian company that manufactures bellows. The flexible water hoses come in a wide range of sizes, featuring an attractive chrome plated outer casing and durable stainless steel fittings. The most popular option for connecting a flexible water line is a nut-nut or a nut-fitting. The only drawback of Italian hoses is their high cost.

It is interesting! Flexible hoses for mixers from the Italian manufacturer are mainly sold in sets of 2.

Below is a table showing the sizes of Italian hoses and their prices:

| Section diameter, inch | Length, cm | Manufacturer, price in rubles | |

| Indrosapien | Emiflex | ||

| 1/2 | 0,4 | 725 | 980 |

| 0,5 | 850 | 1120 | |

| 0,8 | 970 | 1270 | |

| 1 | 1130 | 1620 | |

| 3/4 | 1 | 1050 | 1300 |

| 1,5 | 1370 | 1760 | |

How to choose the right flexible hose for water 1/2 and other diameters

The supply should be chosen so that the fittings, whether nuts or unions, form a reliable connection with the connected devices without the use of additional adapters. To do this, you should purchase products from manufacturers that offer standard sizes of flexible hoses for water supply - 1/2, 3/4 or 1. If you buy a 3/8 size eyeliner, then you can connect such a hose only with an adapter.

If you plan to connect to hot water or a heating system, you need to additionally check the technical characteristics of the products and make sure that they correspond to the temperature of the supplied water and are designed for high pressure in the system. All this information is contained in the passport for the hose. You can find out what water temperature the product can withstand using the marking:

- blue - hose for cold water only;

- red - the product is designed for hot water supply;

- red and blue - a universal hose that can be used to connect cold and hot water.

Depending on the conditions of use of the bellows, a different material is selected from which the braid is made. If you plan to use the hose in an environment where aggressive chemicals are present and high humidity is constantly observed, it is better not to purchase options made of ordinary metal.

It is also necessary to carefully approach the choice of the size of the flexible eyeliner for water. Despite the fact that the bellows is designed for double magnification, experts recommend buying a product with a small margin of length. If the sleeve is constantly taut, this will not have the best effect on the service life. Other important points to look out for when buying:

- Flexibility. If the product bends well, it will be easier to mount it. Flexible hoses are of higher quality.

- Material used to make fittings.Preference should be given to connectors made of non-ferrous metals or stainless steel, and the thickness of the metal plays an important role: thin aluminum will fail faster. To prevent galvanic corrosion, screw connections and union nuts must be of the same alloy.

- Finished product weight. The hose, which is lightweight, was most likely made from silumin, a cheap aluminum alloy. Silumin products rot in a few years.

- Manufacturer. You should only buy products from companies that have been certified in Russia and have received permission to sell.

- Smell. A hose intended for drinking water should not be distinguished by the presence of extraneous chemical odors.

- Section diameter. If you install a 3/4 flexible water line instead of 1/2, then the water noise will be less due to the large outlet.

Important! When buying a certified product, you need to check the availability of a technical passport, which indicates the grade of steel that was used in production, the date of manufacture and expiration date, as well as basic information about the manufacturer. If the seller cannot provide a document, it is better not to purchase the product.

Before buying a hose, you need to conduct a careful visual inspection of the product for defects and check the quality of the corrugation. It is important that the fittings are securely welded to the hose and that there are no traces of corrosion or mechanical damage on the surface. The gaskets are also subject to mandatory inspection, so that they do not look old or cracked.

Features of self-installation and maintenance of flexible liners

After installation, the hose must be in a conspicuous place and must be easily accessible. Before installing the product, you should check the integrity of the corrugation and fastening, because defects may appear during transportation or as a result of improper storage.

When tightening the connectors, do not use excessive force or use gas wrenches for this, as you can strip the threads or damage the product. It is recommended to use an adjustable wrench to tighten the nuts. Other rules to follow during installation:

- Do not kink or bend the cable too much. It should be understood that the hose can only be stretched before installation; after installation, it is prohibited to increase the length of the product.

- After completing the installation of the hose, you need to open the water and monitor the condition of the connections for 5-10 minutes. Then, using a light dry cloth, check the docking for dryness - if drops are found, re-tighten the union nuts.

The main problems that may arise during operation are mainly associated with the purchase of a low-quality product, while a low-quality product is not always distinguished by a low price. Therefore, it is necessary to pay attention to the appearance of the finished product and the quality of the joints made.

Another problem that leads to water leakage is poor crimping of fittings. To avoid buying of dubious quality, hoses should be selected only at certified points and only from sellers who can provide documents for the goods.

Replacing the eyeliner yourself is not a problem, the main thing is to choose the right hose that meets all the parameters

High-quality products can be operated at temperatures above 100 ° C, which allows them to be used as heating pipes. Thanks to high quality materials used in production, hoses are resistant not only to temperature, but also to pressure drops.Even in the case of a sharp supply of water under high pressure, as a result of which water hammer is possible, stainless steel bellows guarantee the integrity of the shell.

Bellows flexible water connection is considered a modern option for connecting plumbing and household appliances that require access to central water supply.