Sooner or later, the issue of designing tracks on a site arises before all site owners. The use of paving slabs for this purpose is one of the simplest, most reliable and beautiful. Therefore, for self-production and installation, you will need instructions on how to make a vibrating table for paving slabs with your own hands. This article will consider all the nuances of assembling the device, as well as the recommendations of specialists for the manufacture of the frame and the choice of the engine.

The vibrating table is used for the production of polymer-sand paving slabs, concrete elements of the fence, figures, monuments, statues, by the method of vibration casting

Content [Hide]

- 1 What is a vibrating table and what is it for

- 2 Varieties of equipment for the production of paving slabs

- 3 Paving slab manufacturing technology: the principle of the machine

- 4 Step-by-step instructions for making a vibration table with horizontal vibration

- 5 Home production of paving slabs: how to choose an electric motor

- 6 Diy vibrating table for paving slabs: rules for assembling a structure

What is a vibrating table and what is it for

A vibrating table, or as it is also called, a vibrating press, is a special device designed for the manufacture of paving slabs. The main advantage of this device is the ability of its working surface to make oscillatory movements. In addition, the vibrating table can be used for other purposes, for example, for the manufacture of monuments, sections of concrete fences, etc.

With the help of a vibrating table and special forms, paving slabs of any size and configuration can be made

As for the independent manufacture of a vibrating table, this is most often resorted to in the case when they want to independently engage in the manufacture of paving slabs for decorating their own yard. Although in some cases this method is used to organize your own small business.

Of course, using a vibrating table, it is definitely not possible to engage in production on an industrial scale, but given that it can be made from scrap materials, and with its main functions - eliminating air bubbles and compacting the composition of forms, such a device will cope perfectly.

Consider in as much detail as possible what will be needed to make a homemade vibrating table, as well as step-by-step instructions for its manufacture.

Varieties of equipment for the production of paving slabs

Vibration tables are different, and before proceeding to manufacture, it is necessary to determine the appropriate option and its features. So, depending on the direction of vibration, the following types of devices are distinguished:

- Horizontal vibration models.

- Vertical vibration models.

These types of devices are divided depending on how exactly the rotor is located in them. At the same time, the first option (table with horizontal vibration) is more popular.

Depending on the installation method, vibrating tables can also be divided into two types: stationary and portable (mobile). But depending on the specialization of devices, there are those that are intended for the formation of products, as well as those that are designed to remove the finished product from the mold using vibration.

Externally, molding and molding tables are practically the same, except perhaps for a special nozzle with holes, on which the mold is installed, from which the finished product must be removed.

If you want to make your own machine for the production of paving slabs, it will be enough to make a vibrating table with horizontal vibration. At the same time, tiles can be removed in two ways: manually (usually flexible forms are used in a home workshop) or by installing a demoulding nozzle.

Paving slab manufacturing technology: the principle of the machine

In order to understand how to correctly make this or that device, you need to understand the manufacturing technology of those elements for which it was designed. Therefore, we will consider the principle of operation of the vibrating table and what each of its constituent parts is intended for.

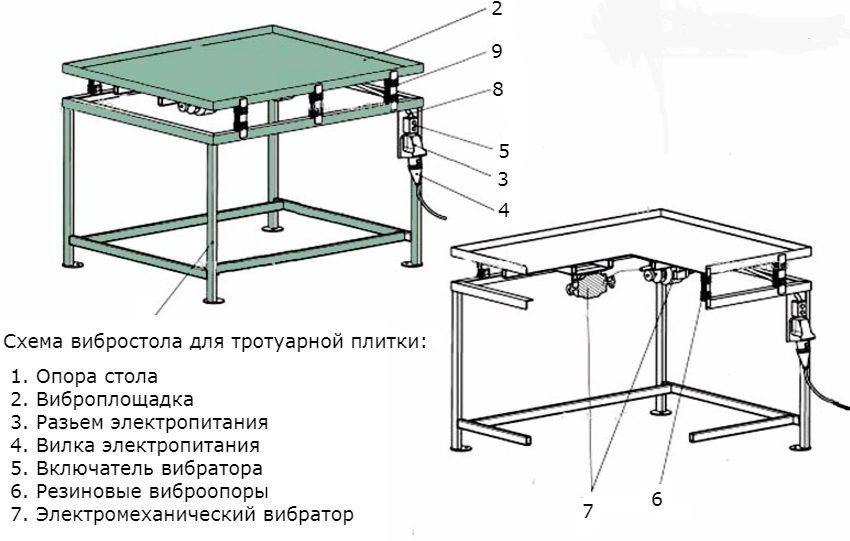

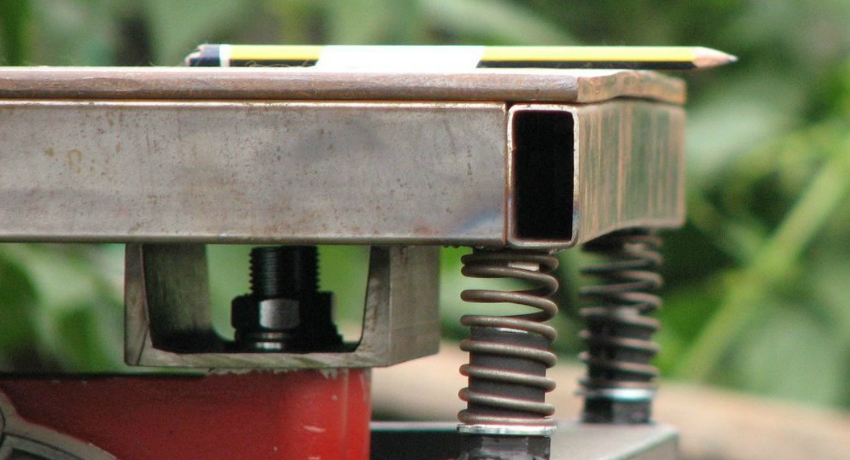

The working surface of the table is attached to the bed by means of a special system of springs, if we are talking about a horizontal vibration device, or by means of suspensions, in the case of vertical devices. Due to the work of the electric motor of the rated power, on the shaft of which the eccentric, the tabletop is set in motion. By shifting the eccentric, the center of gravity changes, resulting in the desired vibration.

For the convenience of working with the vibration table, the height of the base legs should be taken into account

How to make a vibrating table with your own hands: drawings and description

A general idea of the vibrating table device can be obtained by reading the sketch. But for the independent manufacture of such a structure, a full-fledged drawing will be required, which will take into account all the nuances and indicate in advance the required dimensions of each of the elements.

Before starting to create a drawing, it is worth considering the two most popular options: for beginners and for masters. In the first case, the vibropress has a simpler design, but at the same time it allows you to perform the main task - to form products. Assembly, maintenance and care of such a device are quite simple and quite within the power of even a novice master.

Helpful advice! Over time, additional functions such as a sand sifter can be added to this simple design. The main thing is to correctly carry out all the necessary calculations so that the addition of new functions does not cause the main elements to fail.

More sophisticated designs for craftsmen initially combine a vibrating press and a sand sifter. In assembly, such a design is more complicated, however, it is convenient in that it facilitates the process of obtaining the components of the desired fraction.

Step-by-step instructions for making a vibration table with horizontal vibration

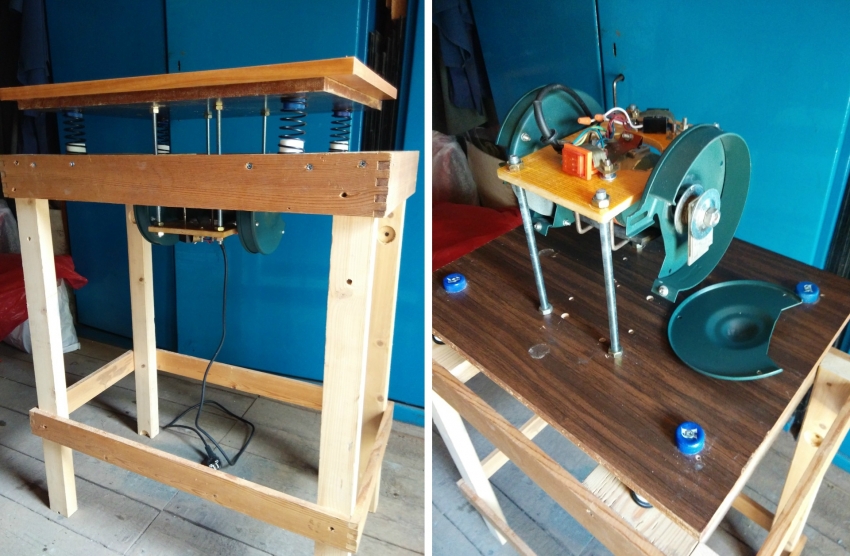

The first thing you should pay attention to before starting work is the size of the countertop. It is believed that the minimum size of the surface should be 600x600, since with narrower sides, the shapes will fall in the process of movement.In addition, a narrow structure will have less stability.

Helpful advice! If in the process of making paving slabs at home, the forms still subside, you can try to reduce their number. This will negatively affect the performance of the device, but in this case the number of tiles damaged due to falling tiles will be reduced.

The size of the vibrating table is largely determined by the required production volume. We can say that there is a direct relationship here - the more elements must be made at one time, the larger the countertop area must be. Naturally, a large vibrating press will require a more powerful motor, and the materials from which the structure will be assembled must be very strong.

As for the height of the vibrating table, it all depends on the individual data of the person who has to work behind it. The standard height that is optimal for a person of average height is 90-100 cm.

Important! When deciding on the height of the table, it is worth taking into account the installation method that will be used. So, for example, if a stationary device needs to be dug into the ground and cemented, then this must be taken into account in advance in the length of the table legs.

Materials and tools required for assembling a vibrating table: prices and characteristics

In order to independently assemble the structure, you will need a grinder, a welding machine, a drill, as well as the ability to handle them. Consider a list of necessary materials that can be found among the handbook materials.

An example of the implementation of a vibrating table for the manufacture of paving slabs with a de-molding nozzle

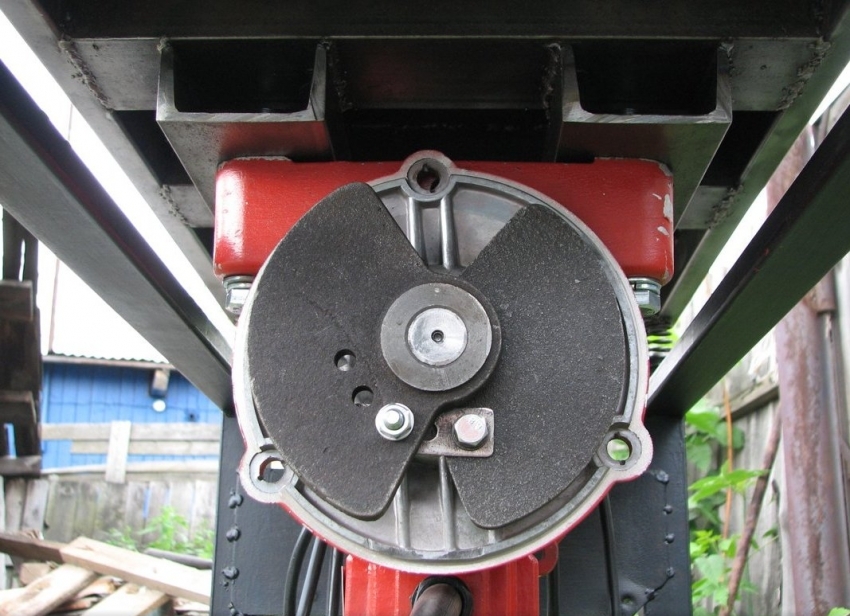

For the countertop, you can use plywood or a sheet of metal of a suitable size. In this case, the plywood sheet should be 14 mm thick. This will allow you to transfer more vibration due to the small thickness, but at the same time provide the necessary structural strength. In addition, this way you can significantly reduce the noise level during the operation of the device. If a metal sheet is used, then its thickness should be within 5-10 mm.

The cost of a sheet of plywood of the required thickness, made from birch veneer, will be about 650 rubles with a standard size of 1525 × 1525 mm. But a sheet of hot-rolled metal 5 mm thick will cost more, about 1000 rubles.

Helpful advice!If a thinner metal sheet is available, it can also be used by reinforcing the structure with metal corners or pipes welded along the center of the sheet and around the perimeter.

Metal corners measuring 50 × 50 mm. They will be required to create the edging of the countertop and during operation of the vibration table will not allow the forms for the production of paving slabs to move from the surface as a result of vibration. Their cost will be about 140 rubles per 1 lm.

Channel for attaching the motor (about 210 rubles / r.m.). It will need to be welded in the center of the back side of the tabletop, having drilled holes in advance that will be used for the bolts holding the motor.

Metal pipes for table legs. Typically, elements with a thickness of 2 mm and a size of 40 × 40 are used for this purpose. The price will be 107 rubles per 1 lm.

Reliability of fastening of all elements of the vibration table ensures the correct operation of the device, the quality of manufactured products and a long service life

Tubes for forming the upper and lower parts of the frame. Since the main load will fall on these elements, it is worth choosing a fairly strong material - 40 × 20 and 2 mm thick for the upper part and at least 20 × 20 of the same thickness for the bottom. The cost will be 84 rubles / r.m. and 53 rubles / r.m. respectively.

Metal plates to be used as a sole for the supporting feet.For this, pieces of metal with a size of at least 50 × 50 and a thickness of 2 mm are suitable.

Related article:

Mold for paving slabs with your own hands: tips for making

Materials for manufacturing and their features. Production of concrete for tiles in-house. General advice.

You will also need a plate for installing electrical equipment and a spring, which are designed to provide vibration. It is quite possible to purchase these elements at autodisassembly. Numerous reviews indicate that the ideal option is to use springs from mopeds, the cost of which at a height of 113 mm and a diameter of 54 mm will be about 500 rubles. They are installed in the corners of the table, and with a large surface area, another one is additionally mounted in the center.

Important!If an additional spring has been installed in the center of the table top, the motor mounting location and support configuration will be changed.

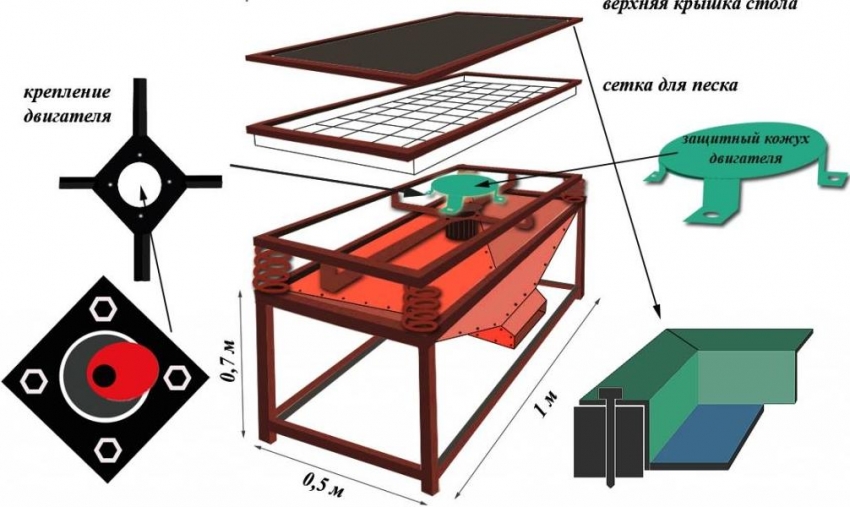

A vibrating table for the manufacture of paving slabs can be made from scrap materials without significant financial investments

Additional aspects to consider when choosing materials for a vibrating table

In addition to the above materials, you should carefully select other component parts, which, although not visible, largely determine the quality of the device:

- bolts for fixing springs. This element acts as a glass for the spring, therefore it must have the proper strength. Sometimes pipe blanks with a length of 50-70 mm are used for this purpose. In this case, it is important that their diameter exceeds the diameter of the spring by 5-10 mm;

- bolts and washers (usually 4 pieces), which are required to fix the engine;

- electrical cable, which must have a sufficient cross section. It is also worth providing for the presence of an outlet and a circuit breaker in the immediate vicinity.

Important! If the diameter of the homemade glass is significantly larger than the diameter of the spring itself, this will lead to the fact that the vibration will be uneven. As a result, the spring will wear out quickly, and the table movement can be called swing rather than vibration.

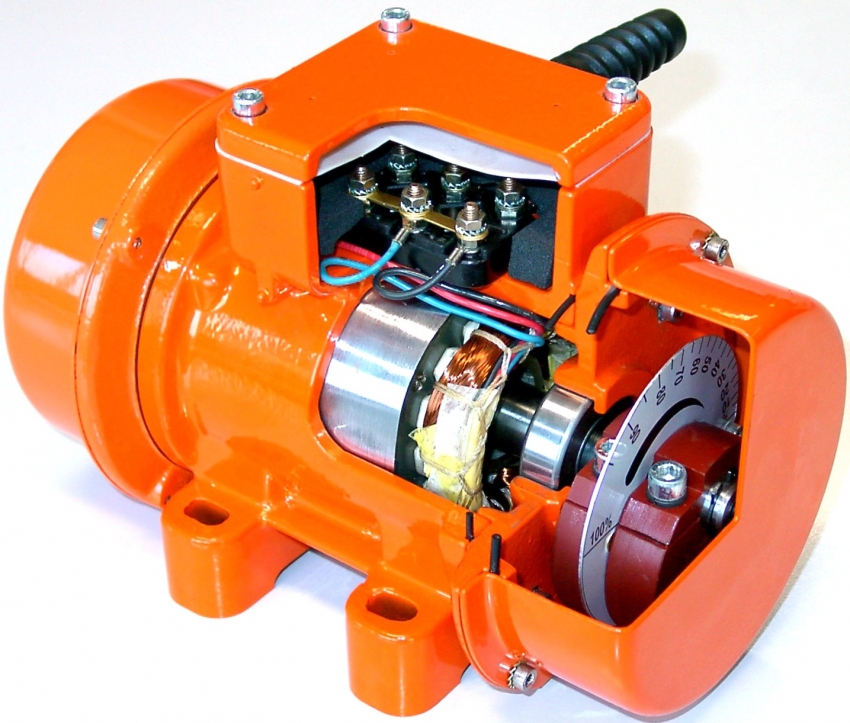

Home production of paving slabs: how to choose an electric motor

The engine is one of the main elements of the vibrating table for paving slabs. Its price may be different, but before making a purchase, it is useful to familiarize yourself with the most popular models, as well as read reviews of users who use this or that option in practice.

Consider the two most popular options: their cost and characteristics:

- IV-99 E with a power of 0.5 kW. Its weight is 14.5 kg, the rotational speed is 3000 rpm, the driving force is up to 5 kN. The device is powered by a 220 V network. It can be purchased at a price of 7,650 rubles.

- IV-98 E is a more powerful model (0.9 kW), which has a greater weight - 22.5 kg and a driving force of up to 11 kN. In this case, the rotational speed is also 3000 rpm. But the main difference between this model and the previous one is the presence of unbalances on the rotor, which rotate together with the rotor shaft. A regular 220 V network can also be used for power. The cost of this model is 8540 rubles.

For the production of a small amount of tiles, this will be more than enough, but if you want to organize a small paving slab factory in your workshop, then it is better to pay attention to the IV-104 B model, with a capacity of 0.53 kW. To power it, a 380 V network is required, but this will make it possible to achieve a driving force of 6.3 kN.

But there are times when it comes to the manufacture of a very small amount of paving slabs for paths to the country, and it is simply unjustified to purchase a motor for this purpose. In this case, craftsmen use an engine from an old washing machine or a pumping station as a basis.In this case, you will have to spend much less money, paying only the turner for some alterations, if necessary.

The only significant drawback of this solution is the fragility of old engines. They are extremely rarely able to withstand more than three dozen working cycles. After this, the axle loosens or the bearing completely wedges. Therefore, if you plan to make a large number of tiles, it is better to purchase in advance a more durable engine that can last the required period of time.

Important! The main task of the engine is to ensure uniform vibration of the surface, because otherwise, the solution may boil in the container, which will not lead to compaction, but, on the contrary, to increased fragility of the products.

Even taking into account the need to purchase all the necessary elements, making such a structure with your own hands is much cheaper than buying a vibrating table for paving slabs.

The power of the electric motor determines the duration of the machine and the required amount of paving slabs produced

DIY vibrating table for paving slabs: rules for assembling a structure

After all the necessary materials are purchased, all that remains is to assemble the structure together. But in order for the resulting device to serve properly for many years, you must adhere to the following rules:

- All metal elements must be opened with an anti-corrosion agent before assembly. This will provide them with reliable protection against rust. The primer GF-021 Lacra, the cost of which is only 125 rubles / kg or paint-enamel, is perfect for this purpose. Moreover, if you have to deal with elements that have already undergone corrosive processes, you will have to purchase more expensive material, for example, EP-0180 primer, costing 188 rubles / kg.

- To fasten the components of the vibrating table, it is imperative to use a welded seam. Bolts are not used for this purpose because over time, as a result of vibration, they can loosen, which will lead to a decrease in the rigidity of the support. Such a solution is allowed only for demountable structures, but in this case it is necessary to regularly tighten the bolts.

- It is very important that the motor that is vibrating must never come into contact with the ground. This is not allowed by the technology of production of paving slabs, and therefore, before proceeding with the manufacture of the first batch, the device must be tested by running and checking the amplitude of oscillations and stiffness of the springs.

- All legs of the support must be the same length. However, in order for the table to be convenient to use, you also need to ensure that the surface on which it will be installed is even. This will avoid distortions and make the process of manufacturing paving slabs for summer cottages as efficient as possible. Consider mounting the table to the surface wisely. This can be done using suitable anchors or concrete mortar.

Useful advice! In some cases, the ideal location of the engine can only be determined empirically. If something does not suit you in the work of a vibropress, you can experiment a little to achieve the desired effect and convenience in work.

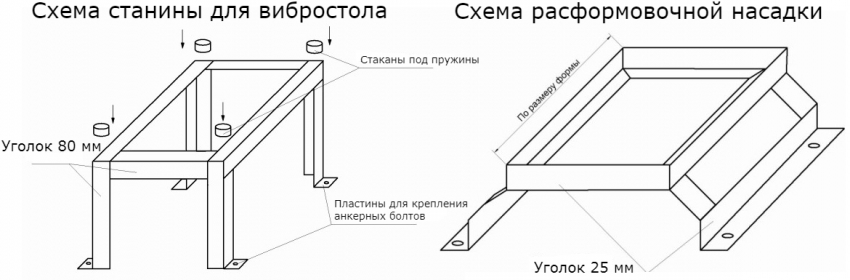

Methods for unbalancing the vibration table motor

Depending on where the engine is installed, it is necessary to unbalance the belt drive unit on the tabletop or the pulley. This can be done in several ways:

- put a round pulley on the shaft, in which a section of the circle has been drilled or ground;

- experimentally select a nut suitable in size and weight, and weld it onto a pulley;

- put the coupling on the shaft, having previously welded on its end a bolt with two nuts, placed across.Due to the fact that the nuts can be moved along the thread, an imbalance occurs.

For reliable long-term operation of the vibrating table, it is worth using steel elements and a cooker for fastenings

As you can see, the independent manufacture of paving slabs for a summer residence is a completely feasible task if you spend time and effort on studying the issue and assembling the necessary device. Although it should be noted that with the help of such a vibrating table it is possible to organize, for example, a small production of polymer sandy paving slabs.