The actions of machines on a large construction site seem to be well-coordinated and very fast. Only yesterday a huge bucket bit into the ground, and today there is already the first level of the future building. This is at large-scale construction sites. But even if you need to put up a country house, the principles are the same: first, you need to prepare the soil, tamp it. Buying expensive mechanisms for short-term use is impractical. A vibrating plate with your own hands is a real and affordable solution.

The vibrating plate is a special unit designed for compaction of soils, concrete surfaces, asphalt pavements

Content [Hide]

- 1 Scope of application and technical characteristics of vibrating plates

- 1.1 Types of vibrating plates: main differences, advantages and disadvantages

- 1.2 Mass classification of vibratory rammers

- 1.3 Vibratory plate device: main units and connection methods

- 1.4 Principle of operation

- 1.5 Manufacturers, recommended models

- 1.6 Which is better: renting a vibrating plate or buying a used one?

- 1.7 How to make a vibrating plate with your own hands: the necessary parts and assembly sequence

- 1.8 Do-it-yourself vibrating plate: operating tips

Scope of application and technical characteristics of vibrating plates

A vibrating plate is a unit whose main function is tamping. It is used in various fields: for soil compaction during construction, landscape planning, for ramming bulk materials (sand, pebbles, gravel), for laying asphalt, paving slabs, paving stones.

The machine is small in size and therefore maneuverable. It can be used both in open areas (when compacting a land plot, parking, road surface, floor in large industrial premises, etc.), and in a confined space (in ditches, trenches, near buildings, near curbs, wells, hatches etc.).

A vibrating plate for compaction of soil and other bulk materials is recommended for use on areas not exceeding 1000 m². Large-sized and more powerful equipment is used for these purposes on large areas.

Each model of a vibrating plate has its own performance indicators, which determine the features of its use and scope. So, when choosing a vibratory plate, you should pay attention to the following technical characteristics:

- base plate dimensions, mm;

- vibration frequency, Hz;

The process of compaction of the required mass by a vibrating plate is carried out as a result of shock vibrations in the unbalance

- the depth of the seal, mm;

- vibration amplitude, mm;

- power, kWt;

- unit weight, kg;

- electricity or fuel consumption, kW / h or l / h;

- maximum productivity, sq.m / h;

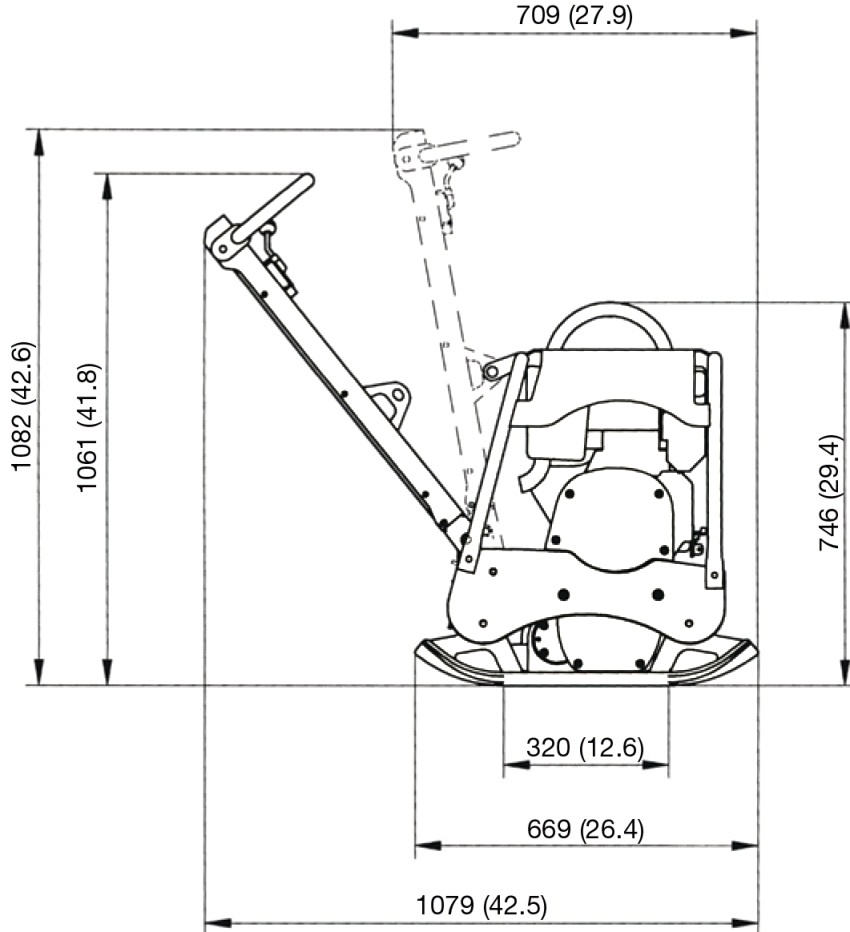

- overall dimensions of the device, mm.

Types of vibrating plates: main differences, advantages and disadvantages

Vibratory plates are divided according to several indicators.The first is the type of engine. Depending on which engine is installed on the unit, the plates are:

- gasoline;

- diesel;

- electrical.

Electric vibrating plate 220 V is the cheapest and most affordable option. According to technical criteria, it is somewhat inferior to the other two types, since it has a low weight and a low degree of ramming. Most of all, this model is suitable for use on a private site, in agriculture, in landscape work. Its disadvantage is the mandatory presence of a power source and limiting the range of action by the length of the cord.

In the absence of a source of electricity or the impossibility of connecting to the mains, it is worth buying a gasoline vibrating plate. It is more expensive than electric, but has no restrictions on operating conditions. It is easy to transport and move. Diesel fuel is cheaper than gasoline, but the engine itself is more expensive. Diesel units are the most powerful and are more commonly used on construction sites. The disadvantage of a diesel vibrating plate is a significant level of noise during operation and high cost.

Useful advice! The engine power directly affects the movement of the plate. At high rates, the unit moves by itself. If the power is low, the cooker may burrow. This disadvantage is compounded if a layer of fine-grained material is rammed.

Vibratory plates are also divided by purpose: for ramming asphalt and soil compaction. The first are distinguished by the presence in their design of a device for supplying water irrigation. It is necessary for wetting, the wet surface excludes adhesion to the base. The surface of such a vibrating plate is smooth, the edges are rounded.

The unit for compaction of soil is heavier, the surface texture of the slab is embossed.

Distinguish between machines with forward motion and reverse. The translational ones move in one direction and have one imbalance. The second type of vibrating plates has a reciprocating direction of movement. They have two unbalances, so they can move in different directions. Vibratory plates are controlled manually or remotely. The latter option is convenient and safe, but the price is much higher.

The vibrating plate with an electric motor is less functional, it has a low weight and a low degree of ramming

Mass classification of vibratory rammers

Along with power, weight is an important technical indicator. It is on her that you need to pay attention when choosing a device model or when creating a rammer with your own hands. According to this parameter, vibratory plates are divided into four types:

| Vibratory plate type | Weight | Features and scope |

|

Lungs |

Up to 100 kg |

Low compaction, used in agriculture, landscape planning |

|

Universal |

100-200 kg |

High frequency low amplitude, used for thin layers of fine-grained soil and asphalt pavements |

|

Medium |

200-500 kg |

Used for thick layers of coarse-grained soil |

|

Heavy |

More than 500 kg |

They have a high vibration amplitude, are used when a high degree of ramming is required |

Useful advice! When choosing a vibratory plate, it should be borne in mind that a heavy device is less maneuverable, but more efficient. If the weight does not correspond to the thickness of the soil and is less than the recommended weight, it will take a long time to compaction and additional fuel or electricity will be consumed.

Before you buy a vibratory plate, you need to decide for what purposes and where it will be used, its weight will depend on this.

Vibratory plate device: main nodes and connection methods

To buy a vibrating plate, it is recommended to choose the price by looking at the characteristics of the units and the price lists of any trading organization.But it is possible to use correctly and even more so to make a car with your own hands only if you know its structure.

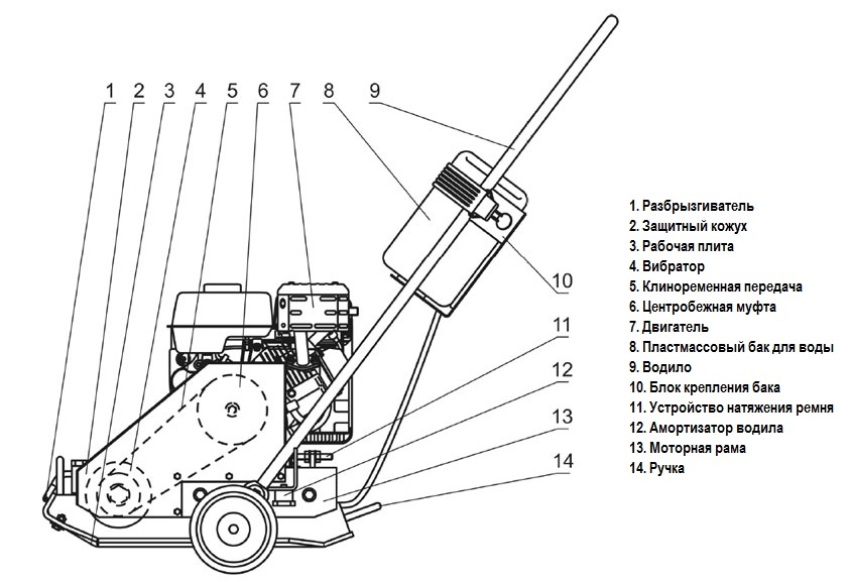

The plate compactor structure consists of the following main components:

- engine;

- vibrator;

- plates;

- centrifugal clutch;

- motor frame;

- control knobs;

- protective covers.

A vibrator is installed on a heavy platform, the basis of which is an unbalanced shaft placed in bearing supports and a cylindrical housing. The structure is fixed with clamps, bolted to the plate. An important part in the device of the vibrating plate, which is also attached to the platform, is the motor frame. It is attached with shock absorbers.

The engine is located above the vibration exciter. The motor and vibrator are connected by a coupling and a V-belt transmission. During operation, the engine creates rotational movements that are transmitted to the vibrator, which converts them into oscillatory ones. These movements are communicated to the plate and then to the surface layer, which is compacted.

If the function of the vibrating plate includes the ramming of paving slabs or paving stones, then the model must be equipped with a softening nozzle made of plastic or a special support surface made of polyurethane.

Principle of operation

The working mechanisms have an impact on the surface of the slab, which produces a certain number of movements in contact with the ground - this is the basis of the principle of operation of this device. Kinetic energy on impact is converted into other types of energy. The pressure on the surface increases instantly, and then the same instantaneous decline occurs. Therefore, besides the force of impact, speed and frequency are effective. As a result of this action, small particles fill the voids, resulting in a very dense, even coating.

Two types of material are used for the manufacture of plates: cast iron and steel.

Useful advice! When choosing a unit with a cast iron stove, be sure to pay attention to the metal grade. A low quality cast iron slab can crack with prolonged use over gravel.

The size of the plate is also important during operation: the smaller its area, the better its tamping qualities. Vibration indicators determine how well the surface will be compacted. If the slabs have the same mass, but different vibrational forces, then the unit with higher values will compact better.

Manufacturers, recommended models

For small-scale work, it is recommended to buy an electric vibrating plate. It is lightweight, has a foldable handle, which allows you to move and transport it to the desired object. The unit has an adjustable frequency converter that allows you to change the vibration frequency, limit starting currents, save energy, and set the operating mode optimal for these conditions. You can buy an electric vibrating plate, the price of which is several times less than types with fuel engines, from any manufacturer where similar products are presented.

Vibratory plates with gasoline engines are most in demand, and therefore are widely represented. Units of the Swiss company Ammann, whose factories have been operating throughout Europe for a long time and have already gone beyond its borders, are very popular. The line of units includes almost all types (from ultralight to the heaviest) diesel vibratory rammers.

Related article:

Do-it-yourself vibrating table for paving slabs: all stages of design and assembly

Features of the assembly of the device and the choice of the electric motor. What materials are needed for the frame. Manufacturing instructions.

Ammann vibrating plates are distinguished by a high level of comfort conditions necessary for the operator's work.The guide handle is isolated from the motor as much as possible to reduce vibration. An additional vibration-damping guide is also patented, which can be used as an option. The engines are economical. There are models that run on both gasoline and diesel.

Splitstone vibrating plates today have taken a strong place in the construction equipment market as a technique that has a high level of quality and reliability.

Among domestic manufacturers, competitive products are supplied to the market by the Russian industrial group Splinstone. Vibrating units have good technical characteristics and low prices. The Splitstone VS-244 vibrating plate is especially worth highlighting. It is the most sought after plate compactor with a balanced combination of performance, performance and cost. With a weight of 74 kg, it compresses a layer of 100 mm. Vibratory plate VS-244 provides compaction of bulk materials, a variety of soils and asphalt in small areas, in confined spaces.

The Shampion PC9045F vibrating plate is a product of American design and high-quality Chinese assembly. This model can be used both for personal purposes and on construction sites. Powerful, compaction depth 300 mm. The noise level is permissible. Air cooling, no bulky water tank. The disadvantage of the unit is the lack of reverse.

Wacker Neuson petrol vibratory plates are German products. The company of the same name (Wacker Neuson) has been operating in Germany since 2007 and specializes in light construction equipment. The products are of high quality and considerable price. The Wacker Neuson MP15 vibrating plate in the model range represents the best option for matching an affordable price and good technical characteristics. Small dimensions allow using the vibration compactor even in narrowly confined spaces. The device has a water-sprinkling system, which allows the use of hot mixtures. Foldable rail and convenient lifting handles ensure easy transport. Wear-resistant bearings extend service life. The unit is linear, this somewhat limits its capabilities.

Compact, lightweight petrol vibrating plate Champion PC9045F is effective for use in confined areas and for small volumes of work

Vibratory plates with Honda engines are in special demand in the construction equipment market. These mechanisms are small, economical and long-lasting. Honda petrol vibratory plates have different characteristics. They are presented in significant numbers in both light and medium-heavy models.

Useful advice! To buy a gasoline vibrating plate profitably, the prices must be viewed at least in 3-5 price lists. Sometimes the difference in their cost is 15-20%.

Which is better: renting a vibrating plate or buying a used one?

If funds are limited or it is impractical to buy a unit for one-time work in a small area, you can rent a vibrating plate. The main advantages of this type of operation are a significant reduction in financial costs and the absence of the need for maintenance. The process of renting a gasoline vibrating plate (however, as well as an electric or diesel one) must include a number of mandatory points:

- drawing up a contract, which stipulates the terms of use of equipment and the obligations of the parties;

- drawing up acts of acceptance and delivery of the unit;

If there is not a large volume and constant work for the vibrating plate, then it is best to rent the unit.

- instructing on safe use.

The rental price of a vibrating plate ranges from 700 to 5000 rubles. per day. It depends most of all on the weight of the machine and the terms of use. Heavy units are more expensive. Long term rental offers discounts. When renting a gasoline vibrating plate, fuel is not included in the payment.The unit is refueled at the expense of the tenant.

To save money if you need to tamp the soil and other surfaces, you can buy a used vibratory plate. But in such a situation, you need to be prepared for the fact that there will be only verbal guarantees. The lifetime of the machine cannot be determined. The degree of wear can only be set relative, by visual assessment, it is not determined by the date of issue. There is always a risk of buying a unit that is being disposed of for some technical reason. In most cases, it is not possible to return a used mechanism to the seller.

Useful advice! Having decided to buy a used vibratory plate, be sure to check the operation of the engine. If there are problems, they will accordingly manifest themselves with unusual noise, launch delay or other abnormalities.

Vibratory plate rental is a very popular service among builders. there are a number of advantages of renting over buying

How to make a vibrating plate with your own hands: necessary parts and assembly sequence

Of course, you can buy an electric 220 V vibrating plate, or you can make an in no way inferior mechanism with your own hands. This option has enough advantages:

- significant cost savings (at least 50%);

- confidence in the build quality;

- creating a mechanism with the desired characteristics;

- moral satisfaction.

Do-it-yourself electric vibrating plate 220 V does not require drawings, since the design is not complex and it is inappropriate to waste time on calculations in paper form. As an engine, as an option, you can use the platform vibrator for the vibrating plate IV-98E, operating from the 220 V.

The platform can be based on sheet metal 8 mm thick and 45x80 mm in size. You will also need 2 channels, 2 elastic cushions for fixing the handle, M10 bolts for an electric motor or M12 for a gasoline one, 2 plastic wheels, a piece of pipe, a hollow pipe 1.2 m long.

The sequence of assembling a vibrating plate with an electric motor with your own hands:

- the cover is removed from the electric motor so that it is possible to regulate the strength of vibration;

- on a sheet of metal, two cuts are made at a distance of 10 cm from the edge, 5 cm deep. The edges are bent along the cuts with a hammer. This is necessary so that the slab does not burrow into the ground;

- a vibrator is attached to the plate with the help of channels. The edges should not protrude beyond the work surface. Fastening method - welding;

- the vibrator is attached to the metal with M10 bolts. The holes on the channels are drilled at the same distance as the motor mounting holes;

- a handle is made from the pipe and attached to the base through the pillows. The pillows dampen vibration;

- then a piece of pipe is welded, wheels are attached to it - for transportation.

Useful advice! A homemade vibrating plate should be tested on a small area of a soft loose surface, giving a minimum load. This will reduce to zero the risk of injury in case of malfunction of the mechanism.

A self-assembled electric vibrating plate is a reliable mechanism that will not yield to factory ones in terms of service life. Only the low aesthetics of the homemade device can be considered an insignificant drawback. Although, if desired, this drawback can be easily eliminated by painting the details in bright colors.

A vibrating plate with your own hands is a quite feasible task if you have all the necessary components

Do-it-yourself vibrating plate: operating tips

A vibratory rammer created by your own hands will become an object of self-respect and will ensure uninterrupted operation if you adhere to certain operating rules:

- before turning on the unit, check the strength of the fasteners and the presence of damage, eliminate the identified deficiencies before use;

- after switching on, let the engine warm up for 2-3 minutes;

- use the vibrating plate only on loose surfaces;

- timely replace air filters and oil in gasoline models (every 100 hours of operation);

- prevent engine overheating;

- keep the device clean and perform preventive maintenance;

It is not advisable to overload the motor of a homemade vibrating plate by ramming too hard or moving too fast

- if a polyurethane mat is used, it must be cleaned after each use.

Useful advice! If multiple layers need to be compacted, each layer should be compacted separately. This will ensure the quality and prolong the durability of the mechanism.

To reduce vibration during work, you need to make loops of thick rope on the handle and hold on to them. In this case, the impact on the hands and upper limbs is significantly reduced. If you need to water the surface, you should attach a water tank and a hose from which water will be supplied and consistently irrigate the required areas. Care must be taken to keep moisture away from the engine.

If after one pass the surface is not compacted enough, it is recommended to repeat the action until the desired result is achieved. Most often, you need to tamp one section by passing it 5-6 times.

The advent of vibrating plates has accelerated the process of compaction of surfaces hundreds of times. A variety of modifications allows you to choose the necessary mechanism for high-quality and comfortable work. The possibility of making a homemade vibrating plate made it possible to use the unit by people with various material capabilities.