In order to cut tiles, there are special tools - tile cutters. The choice of this device directly depends on the intensity of its use. For quite large volumes of work, it is customary to use an electric water-cooled tile cutter. This device allows you to process not only ceramics, but also porcelain stoneware. The article will consider the main models and characteristics of such a product.

When carrying out large-scale renovations, when you need to cut a large number of tiles or porcelain stoneware, you must use an electric water-cooled tile cutter

Content [Hide]

Electric water-cooled tile cutter: advantages

Devices that belong to this group are characterized by high efficiency and long service life. The water supply system includes elements such as: a hose and a reservoir with a liquid. The pumping mechanism that draws water is activated simultaneously with the cutting element.

The water cooling system allows to increase the working time without interruption, increases productivity, increases the life of equipment and cutting tools

This cooling circuit achieves two main objectives. It primarily prevents the diamond blade from overheating. Equally important, a lot of dust is generated when tiles are cut with conventional mechanical devices. Using a water tile cutter overcomes this problem, which makes the process of processing ceramic material more convenient. Dust trapped in water particles immediately settles on the device.

There is a special container under the working surface for cutting tiles, the height of which can be different. It depends on the model of the water-cooled device. As a rule, this figure is no more than 10 cm. Dust with water flows down the blade, as a result of which it gets into this reservoir. It should be cleaned from time to time to ensure proper operation.

Mechanical hand tools (for example, Sigma tile cutters) require effort when working with tiles, and also do not save you from dust. In turn, electrical tools do the job. And also they can function offline.In this case, the hose that delivers water is connected to a container that is placed under the work surface.

The movement of fluid in an electrical unit is carried out in a closed cycle. This allows you to use the minimum amount to perform a large amount of work.

Using an electric tile cutter, you can give the tile almost any shape, but do not forget that the price of such equipment is quite high

The device and principle of operation of an electric water tile cutter

The device has traditionally been quite large. It is a fixed-type fixture and functions by being connected to the mains. To ensure maximum convenience when cutting tiles, its platform is located at a height of about 1 m.This allows the master to perform all the necessary manipulations while standing, while maintaining a comfortable body position. The distance from the floor to the desktop can be adjusted to suit individual preferences.

From a constructive point of view, such devices have a certain similarity to circular saws. The device consists of several main elements, including: an electric motor, a cutting wheel, a work surface and a bed. And also a tile cutter of this type is equipped with a functional part adjustment system and special fixing devices.

Note! As a rule, a diamond disc is used as the main cutting element in such devices.

The cooling system functions quite simply and provides a fluid supply to the point of contact of the cutter with the ceramic product. Thanks to the high quality of the diamond blades for tile cutters, the devices can be used for processing various materials such as porcelain stoneware, stone, concrete, glass, etc.

The water-cooled electric tile cutter has a diamond blade cooling system to ensure a longer service life

Varieties of water-cooled tile cutters

Today there are a huge variety of models of these devices. They are produced by different brands and differ from each other not only in appearance, but also in technical characteristics. All electronic tile cutters are usually divided into two main types:

- manual;

- professional.

Manual. These tools have a simple and convenient design. They can operate both from the electrical network and from the storage battery (accumulator). According to the principle of operation, they resemble angle grinders, with the only difference that tiles are used as products for processing on them.

The electric manual cutter includes a handle, a support called a soleplate, and a reservoir for fluid. As well as elements that allow you to adjust the position of the functional part. It is desirable to work with such a device only in the horizontal plane. This is due to the fact that, being in a vertical position, the product does not prevent the formation of dust. For more complex work, there are manual professional tile cutters.

The household electric tile cutter is not suitable for cutting hard materials such as porcelain stoneware and granite, it can only work with tiles or glass

Today, in the construction market, you can find more voluminous models that run on a battery. The main advantage of such devices is their autonomy. They are a kind of transitional link between hand-held and professional devices.

In turn, professional devices are classified based on the location of the motor. It can have two positions:

- above the work plane;

- below the work plane.

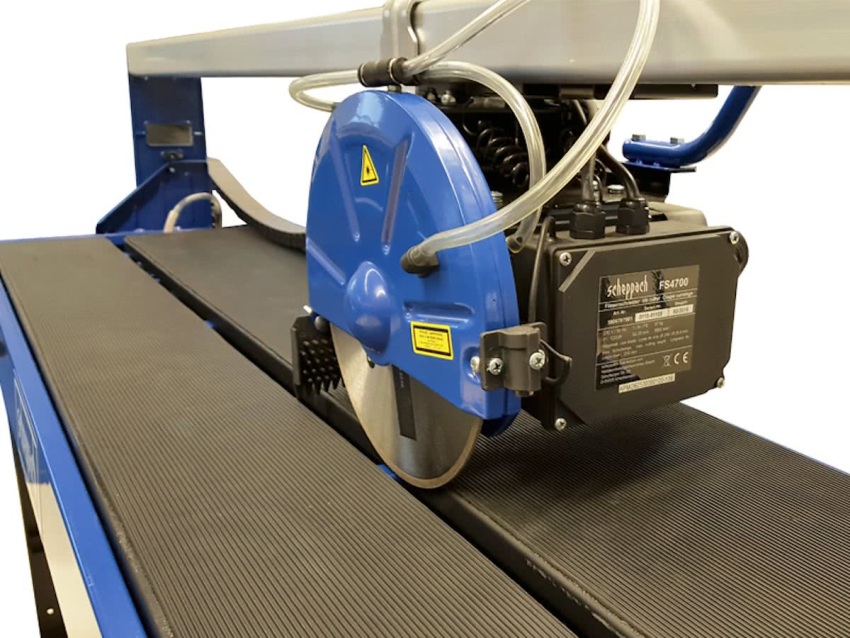

Devices with a motor at the bottom. The main characteristics of such models include high cut quality, as well as good protection against dust during operation.The cutting element is represented by the same diamond-coated disc. The design feature of this device is the location of the functional part. The upper half of the cutting wheel is above the work plane and the lower half is in the water tank.

This position of the motor allows the production of compact equipment that is versatile. Such devices are highly popular in the construction market precisely due to their small dimensions. When renovating an apartment, it is always difficult to find enough space for a large model.

The professional water-cooled tile cutter has sufficient power and performance, it is large in size and its price is high.

Bottom-drive devices allow cutting rather large ceramic and other finishing materials. This is due to the fact that there are no limiting structural elements on the work surface.

Helpful information! Of the disadvantages of stationary models that have a motor in the lower part, it can be noted that during the cut it is necessary to move the workpiece with your own hands. Therefore, it is desirable to have experience to work on such a tile cutter.

Models with a motor on top. They belong to professional electric tile cutters. Devices of this type are rather large and have a complex design. Sufficient experience is required to operate a water-cooled overhead electric cutter. All devices with a motor located at the top are divided into two types:

- console;

- pavement.

In the first case, the device is equipped with a console, which is fixed with special fixing elements. The working platform of such a device is flexible. Electric bridge cutters include a movable functional part that moves with the help of special guiding elements.

More reliable and high-quality is the electric water-cooled tile cutter, the motor of which is located at the top of the tool

Electric tile cutter DeWalt D24000

This type of device is versatile. It can be used to cut ceramic or paving slabs. And also often the device is used for stone processing. The design of the device includes two supporting elements, which not only increases the accuracy of the cut, but also allows it to be performed at an angle of 45 °. To protect the cutting wheel, it is housed in a special casing.

This type of machine is quite common in small businesses. He is considered one of the best tile cutters and is capable of quite large amounts of work.

Cutting accuracy in such a device is ensured by means of special guides. They are made of stainless steel, therefore they are resistant to corrosive effects. Using this machine allows you to make cuts up to 61 cm long.

The water cooling system of this electronic tile cutter includes double water jet channels. If necessary, their operation can be adjusted so that the diamond blade receives the optimal amount of coolant. And also a device of this type is equipped with reservoirs for catching water droplets, which are located on the back and sides.

The DeWALT D24000 machine has two stops, which increases the accuracy of cuts and makes it possible to cut at an angle of 45 degrees without preliminary marking of the material

This device operates from a network with a voltage of 220 V. Its power indicator is 1600 watts. Spindle speed - 4200 rpm. The device is rather bulky and weighs 32 kg. The price of an electric water-cooled tile cutter of this type averages 64,000 rubles.

Note! DeWalt D24000 has a wide range of capabilities.In addition to the usual longitudinal cuts, such a device is used to organize holes for sockets.

Electric tile cutter BISON ZEP-800S: characteristics

Such a device has good performance and includes an electric motor with a power rating of 800 watts. Like the previous model, this device is equipped with a water cooling system. All important elements of the machine, including the working surface of the table, are made of stainless steel.

Sawing of facing materials can be done with this device at different angles (from 0 to 90 °). The maximum length of the cut is 53.5 cm. The device operates on an electrical network with a standard voltage of 220 V. The motor in this electric cutter is located on top, therefore it belongs to the professional group.

ZUBR ZEP-800S is a powerful enough electric tile cutter for cutting various types of ceramic facing, paving and floor tiles

The spindle speed is 2950 rpm. The weight of such a device is approximately 30 kg. Such a device is quite common and has many positive reviews among consumers. The price of the ZUBR ZEP-800S electric tile cutter ranges from 11,000 to 13,000 rubles.

Desktop tile cutter Practice Profi 1872

Such a device is desktop and allows you to quickly and accurately process tiles. The engine power rating of the unit is 72 watts. Of the features of the device, it can be noted that it allows you to cut facing materials without applying preliminary marking. This is achieved by a parallel stop on the work plane.

A tabletop model of this type is characterized by its compact dimensions, which allows it to be moved without any effort. The unit is adapted for cutting products, the length of which does not exceed 30 cm. It operates from a conventional power supply with a voltage of 220 V. In this case, the spindle rotation speed reaches 2800 rpm.

This electric cutter is equipped with water cooling and has a special fluid reservoir. With it, you can cut not only ceramic tiles, but also porcelain stoneware products.

The set of the PRAKTIKA 1872 Pro electric table cutter includes a case that makes transportation of the machine simple and convenient

Practice Profi 1872 is small in size and weighs only 16.5 kg. The cutting depth of the table-type device is somewhat less than that of professional machines and is 20 mm in this case. How much does this type of tile cutter cost? You can buy this unit for 7,500-8,000 rubles.

Related article:

Manual tile cutter: price, review of popular models and nuances of use

Mechanical and electrical manual tile cutters. Review of manufacturers. Councils for selection and use.

Features of the tabletop tile cutter CORVETTE 460

This unit has a lot of positive qualities, therefore it is popular in the construction market. First of all, it is worth noting its versatility. The device can be used to cut not only ceramic, but also paving slabs. The cut can be made in three positions: straight, at an angle and by combining the first two.

Electric tile cutter "Corvette 460" is designed for cutting with a diamond disk to the size of all types of ceramic facing, floor and paving slabs and is equipped with a sufficiently powerful asynchronous motor

The device includes two options for an emphasis: parallel and angular. The motor of this water-cooled electric tile cutter is asynchronous. The spindle speed is 2850 rpm. A special casing is used to protect the diamond disc. The power rating of the device corresponds to its small volume and is 600 watts. Such a device works from a network with a standard voltage of 200 V.It can be used to cut facing products up to 36 cm long.

The approximate weight of the unit is 11-12 kg, which makes it easy to transport and use. The average cost of this small-sized model is 4300 rubles.

Electric tile cutter RUBI ND-180-BL Standard

The device of this type has good technical characteristics and is used, as a rule, to perform a fairly large amount of work. The main advantage of the device is noiselessness when working with facing materials.

Note! With this model, you can cut veneering materials at an angle of 45 °.

The main materials that are processed on this device are ceramic tiles and porcelain stoneware. Thanks to the parallel stop, the machine is capable of making fairly accurate cuts.

RUBI ND-180-BL Electric Water-Cooled Tile Cutter Standard allows you to cut workpieces of any size without the design constraints of the desktop

Complete with a reservoir for cooling the diamond blade. It is powered from a 220 V network. The maximum power of the device is 550 watts. Due to its low weight (10 kg), it is easy to transport. The average price of a RUBI ND-180-BL water tile cutter is 6900 rubles.

Which is the best to buy a refrigerated electric tile cutter: tips

First of all, it is recommended to determine the purpose of the unit. This will determine its cost and further nuances of choice. If you want to purchase a device for one-time use, then it is best to buy a manual mechanical model. Electronic devices are more expensive, however, due to their characteristics, they have many advantages.

Which is the best professional tile cutter to buy? Consider what factors you need to pay attention to when choosing such a unit:

Electrical parameters. Before purchasing a device, experts recommend finding out what voltage is required for its operation. As a rule, at home it is not possible to use models that require an indicator above 220 V.

The second important selection criterion, which also applies to electronic parameters, is power. To work with thick ceramic tiles or any other material, you will need to use a more productive device. The minimum engine power of such a unit must be at least 1500 watts. Such models are equipped with special diamond discs with a diameter of 35 cm (to increase the cutting depth).

The choice of a model of a water-cooled electric tile cutter is made depending on the specifics of the work

If you need a device for processing ceramic tiles of medium thickness, then its power should be from 800 to 1400 watts. In this case, the diamond wheel will have a diameter of 25 cm. Less powerful devices are also suitable for cutting standard ceramic tiles.

If needed, you can buy a water-cooled electric tile cutter that includes a protective system. Some handheld models have a mechanism that prevents unintentional starting. In practice, it looks quite simple: two buttons that must be pressed simultaneously for the unit to start working.

Note! Before buying a water tile cutter, carefully inspect the insulation of live elements. It is also worth considering that some units require grounding.

Desktop options. The cutting depth is selected depending on the thickness of the tiles. It is advisable to select a model that takes into account the regulation of the cutting blade. The table in some models, in which the motor is located at the bottom, tends to tilt. This is necessary in order to process facing products at a certain angle.

When working with heavy materials, the strength of the bed is important, which determines the total weight of the electric machine.

Experts advise paying attention to the quality of the base of the unit (bed). It must be made of durable, corrosion-resistant material. The size of the working plane determines the size of the tile that can be cut on it. The surface of a good electric tile cutter should be at least 60x45 cm.

Water supply parameters. Devices in which the engine is located at the bottom are equipped with a reservoir located under the working surface. Part of the cutting wheel during operation is constantly in it and, thus, is cooled. Masters recommend choosing a model with a medium-sized container.

Top engine units have a more sophisticated cooling system. In this case, water from the container flows to the cutting part by means of a pump. Before you buy a professional electric water-cooled tile cutter, it is advisable to pay attention to the presence of filters for cleaning the liquid. They are not present everywhere. The power of the pumping device and other parameters of the water circuit, as a rule, are indicated in the corresponding documentation.

When choosing tile cutting machines, you need to pay attention to the presence of adjustment of the parameters of the cut and the location of the plate, as well as additional protection of the motor against overload and overheating

How to cut tiles with a tile cutter water cooled?

Cutting tiles is a serious process, so it is recommended that you familiarize yourself with some of the nuances before starting work. All electronic units, which include a water circuit, have a certain sequence of cutting facing materials.

The functional part of water tile cutters is represented by a diamond wheel. The use of such a cutting element allows you to quickly and accurately perform fairly large volumes of work. When sawing, remember that the facing product must be moved towards the disc.

Helpful information! An important role is played by what material the tiles are made of. The stronger the structure of the product, the more pressure must be applied to it during cutting. Experts recommend gradually increasing the pressure during operation.

In order to avoid jamming of the cutting disc and to minimize the percentage of vibration, it must be fixed on the table. The water that accumulates in the tank during operation gradually becomes polluted, therefore it is necessary to change it in time.

It is best to press on the workpiece from both sides. This will eliminate the likelihood of skewing and chipping. In some cases, the diamond wheel may jam. Moreover, this does not depend on the cost of the unit and its quality.

During the cutting process, it is necessary to press on the tile with a certain effort, it will depend on its composition, thickness and density

And, of course, do not forget about the elementary precautions when working with such a tool. Safety precautions include the use of special glasses to protect the eyes, as well as noise protection headphones.

How to cut with a tile cutter at an angle: recommendations

The processing of facing materials at right angles is not very difficult. More problems and questions (especially for novice craftsmen) are caused by cutting tiles diagonally. It should be noted right away that manual models are not adapted for such operations, therefore, an electronic unit with a water circuit will need to be used.

Changing the angle in such devices is done by changing the position of the cutting head. Special screws are used to fix it. Depending on what angles of inclination can be used when working with tiles, all electric cutters are divided into three types:

- cutting only at right angles (90 °);

- allowing the processing of tiles at two fixed angles (90 and 45 °);

- functioning in the range from 45 to 90 °.

The dimensions of the working plane allow you to cut tiles not only in standard sizes (30x30 cm), but also products, the length and width of which reaches 1 m. A long table is one of the characteristic features of a professional tile cutter. However, different models differ from each other and, first of all, you need to look at their performance.

Almost all models of electric tile cutter can cut tiles and porcelain stoneware at an angle of up to 45 degrees, but for different materials you need to select your own disc

When cutting tiles diagonally, be very careful to avoid chipping. Experts do not recommend putting too much pressure on the facing product when processing it.

Thus, there are several varieties of electronic tile cutters, each of which is selected depending on the purpose. When choosing this device, you should pay attention to its external elements. They must not be damaged. It is also recommended to study the passport of the electric tile cutter. Reviews of different models can be easily found on the Internet in specialized forums.