A hacksaw for metal is a special tool that is used to cut metal workpieces, ceramics, wood, plastic, foam and organics. Today, there are several varieties of such a device, which have certain characteristics and individual parameters. This article provides detailed information about the design features, types and rules for choosing a universal tool.

Content [Hide]

- 1 Varieties of hacksaws, characteristic features of products

- 2 Varieties of hand saws for metal, depending on the scope of use

- 3 Non-standard types of hacksaws for metal

- 4 The main criteria for choosing the right hand tool

- 5 Rules and features of working with a hacksaw for metal

- 6 Rating of hand saws for wood and metal

Varieties of hacksaws, characteristic features of products

A hacksaw is a carpentry and metalwork tool, it is a type of saw. Its main purpose is to cut workpieces and products from different materials.

Saws are classified into hand-held tools and electric hacksaws. The latter version is equipped with an engine, which ensures quick and less labor-intensive work. Such a saber hacksaw can be presented in the form of a power or cordless tool. The first type of device operates on the electrical network. This hacksaw is a pretty powerful tool. Its only drawback is the presence of a cord that limits the area of action.

Reciprocating tools can be divided into electric hacksaws for metal, wood and stone, their blades differ in length, shape, size and number of teeth.

The cordless hacksaw is a more mobile device that runs on battery power. This type of device is less productive. One battery charge is not enough for long-term use of the tool.

Depending on the purpose, there are hand saws for wood and metal. The first type of device consists of a working blade equipped with sharp teeth and a handle for easy grip. This tool is often used for cutting drywall and aerated concrete.

A hand saw for wood can be classic, circular and thorn. The first option is used for longitudinal or transverse cutting of a workpiece. The blade teeth have a triangular shape and are located with a pitch of 1.5-6.5 mm. To improve your sawing performance, you should study the information on how to sharpen a hacksaw.

The circular saw is used to cut curved pieces thanks to a narrow blade with fine teeth that can be positioned on one or two sides. A tenon device is used to remove protruding grooves and tenons in order to obtain a clean cut.

A hacksaw for metal is a versatile tool that can cut a workpiece made of any material, including plastic, wood, foam plastic, aerated concrete, etc. The working blade of such saws has small teeth, which makes the cut more accurate and clean. During operation, small chips are formed.

Hacksaw for metal: tool design

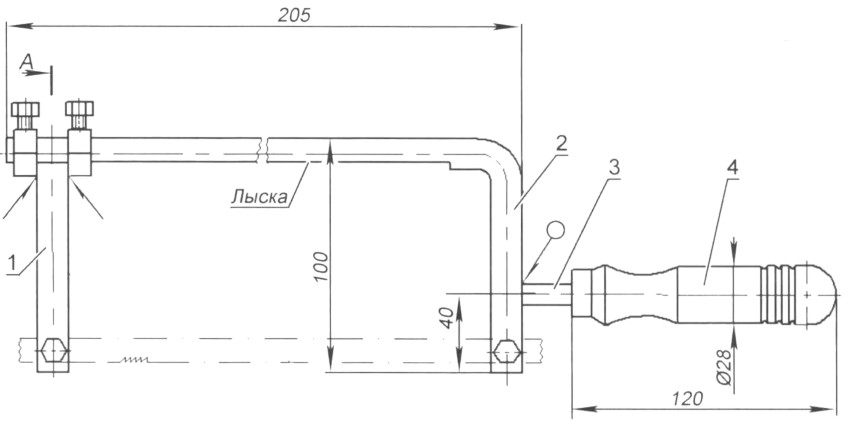

The metal tool has a simple design. It looks like a bracket, between the ends of which the canvas is fixed in a taut position. The device consists of a frame, a cutting element and a handle.

The frame is intended for fastening the canvas. It can be made from different materials. For cutting dense metal blanks, frames made of high strength composites are used. The design of an element is determined based on the conditions of its use. If it is often necessary to cut in hard-to-reach places, you should purchase a small device that makes it possible to adjust the slope of the canvases.

The cutting part is represented by a thin steel band. The blade is installed in the frame so that the teeth are on the opposite side of the handle. It is the most fragile element of the structure, therefore, when cutting, it is required to act especially carefully and carefully, since negligence can lead to damage to the product.

The cutting blade has wedge-shaped teeth. When choosing a fixture, you should pay attention to whether the cutters have been hardened, which increases the service life and productivity of the tool. This will also affect the decision of the question of how to sharpen a hacksaw (information can be found on the Internet). It is better to give preference to hardened, made of nickel-plated steel and having a dark color or bimetallic, painted in any tone options.

Important! For cutting hard workpieces, you should choose blades with small incisors, and for soft workpieces, it is recommended to use a cutting element with large teeth.

The handle is an important part of the tool, due to which the convenience and safety of the hacksaw operation is ensured. The best is the two-piece handle, which is equipped with durable rubber and special soft inserts. The handle can be placed on the side or on top of the hacksaw.

Varieties of hand saws for metal, depending on the scope of use

The main purpose of a manual hacksaw for metal is to cut workpieces from durable metals, cut seams and grooves, trim products. This tool can also be used for sawing ceramic, wood, plastic, organic and foam objects.

Depending on the scope of use, hand saws for wood and metal can be divided into three types: household, professional and hand saws. The first version of the tool is intended for home use when solving simple tasks. The models are distinguished by their simplicity of design and ease of use. Such products are made in a wooden frame located longitudinally to the canvas and combined with a wooden handle. The cutting element is screwed to it with screws.

Professional-grade hand saws are equipped with a durable and comfortable rubberized handle, so the tool can be used for a long time.The cutting blade is set at a specific angle, which allows for unusual cuts. This type of tool makes it possible to create a variety of cuts of workpieces, is distinguished by high quality construction and durability.

The hacksaw handle looks like a staple. Thanks to this configuration, the tool can be used in hard-to-reach places, which is clearly shown in the photo of hacksaws for metal. This attachment is ideal for making internal cuts. The cutting blade is attached to one side only. There are folding options for a mini hacksaw for metal.

Hacksaw blade options for metal

Cutting blades for hand saws for wood and metal can be made of different materials. The most economical and lightest option is a carbon steel blade. Such a blade is used for household saw models. It has a low cost and a short service life.

Toothed blades with partial heat treatment are considered to be a more technological, wear-resistant and durable option. The fast cutting elements are cobalt steel blades. Such canvases are flexible and fairly strong. They are used for cutting hard workpieces. This ensures high quality and cutting speed. This option is also often used for electric hacksaws for metal.

Hardened blades are suitable for directional cuts. It is advisable to use them for cutting at a certain angle.

Bimetallic blades made of cold-rolled carbon steel are distinguished by their high strength and reliability. A strip of high-speed steel is welded onto its surface by an electron-beam method, on which there are cutters.

Cutting blades are classified according to the type of saw set, which can be made along the blade or along the cutters. In the first case, the teeth are retracted from the edge of the file alternately to the left and to the right with a bend height of 2-3 mm and a deviation of 0.25-0.6 mm. This layout is typical for canvases with small incisors.

When setting along the cutters, the blade teeth are bent in different directions. The alternation is performed according to the step size. With a small value, 2-3 incisors are abducted, with an average - 1 tooth to the left and 2 to the right, the other three are in place. For large strides, the incisors are abducted alternately.

Canvases are single-sided and double-sided. In the first case, the cutters are located on one side, and in the second, they are on both sides of the blade.

Non-standard types of hacksaws for metal

A diamond wire can be used to cut hard alloys, ceramics, stone, concrete and metal. The element is made of alloy steel coated with diamond sputtering in a layer of 2 mm. At the ends of the string there are loops, which are designed to fix the product on the hacksaw frame.

The diamond thread is able to cut the workpiece efficiently, quickly and without much effort. Her work can be compared to a professional version of a hacksaw for metal. However, the cost of a diamond string is much lower. The thread in 1 minute cuts a solid workpiece with a depth of 1 mm. A glass product 0.5 cm thick will be cut in 40 seconds. The diamond string can cut a stone in 30 seconds at a cutting depth of 1 cm.

Important! For high-quality and convenient cutting of workpieces, the thread and material should be moistened before starting work, repeating the procedure during execution.

Another option for a hacksaw blade for metal, the price of which is much higher, is a steel thread. Its surface is coated with tungsten carbide.The products are produced in 300 mm length and 2.7 mm in diameter. Such a thread is capable of performing high-quality, accurate and accurate cutting of the workpiece. With its help, you can make a curved or circular cut.

Manual hacksaws for metal can have not only a different cutting element, but also the very shape of the product

The main criteria for choosing the right hand tool

When choosing a tool, one should be guided by certain characteristics of the elements. A high-quality and reliable device is carried out in accordance with the requirements of the current GOST. A hacksaw for metal should be practical. It is essential that cuts in any direction and at different angles are carried out quickly and easily.

Useful advice! It is better to give preference to hacksaws, which are able to cut metal not only with straight forward movements, but also with reverse ones.

The cutting blade can have a different shape of the cutters, which varies depending on the inclination of the toothed element and varies between 0-10 degrees. The pitch of the teeth is selected based on the strength and thickness of the material to be processed.

It should also be borne in mind that when working with a workpiece, no more than 3 teeth can simultaneously exert pressure on it, provided that the cutting is carried out at a right angle. To cut soft workpieces, it is enough to purchase a tool with a tooth pitch of 3.5 mm; for a harder material, you will need a hacksaw, in which the cutters are located at a distance of 5 mm.

The size of the blade is determined by the dimensions and volume of the processed workpieces. The length of the cutter can be 290-700 mm. When choosing a canvas, you should pay attention to its appearance. The element must be clean, level and capable of returning to its original appearance after being bent. The surface must be free from cracks, damage, corrosion or other defects. The most demanded is a 300 mm metal hacksaw blade.

Related article:

DIY metal cutting machine: manufacturing technology

Features of structures, preparation of tools, step-by-step technology for manufacturing machines based on a disc and a grinder.

Saws are very reliable, safe to use and durable, in which the handle is represented by a single piece that does not have internal voids. Hollow variants quickly fail. They break easily even with the slightest impact.

Useful advice! When choosing a hacksaw, you should take the tool in your hand, while the palm should fit the handle quite tightly.

When buying a saw for metal, you should not give preference to too cheap options. At the same time, it is also recommended to refuse to purchase expensive models, since this is not always justified from the point of view of the optimal ratio of cost and quality of the tool. The average price of a hand hacksaw for metal is 600-1200 rubles.

When choosing a hacksaw, you need to take it in your hand, the palm should tightly fit the handle of the tool

Rules and features of working with a hacksaw for metal

To work with a hacksaw for metal, you do not need to have special skills and abilities. However, when using the tool, certain rules must be followed.

Before cutting the workpiece, it is necessary to correctly insert a metal blade for a hand saw. First, you need to straighten it in width. Then the ends of the canvas are installed on the seats and fixed with nuts. Correct fastening eliminates the possibility of vibrations during the use of the tool. The cutting element should ring like a guitar string with a click. However, do not overtighten the nuts as this may result in damage.

Important! The optimum blade tension is determined by first screwing it onto the frame without further intervention.

To minimize the likelihood of breakage of the toothed blade, the workpiece must be fixed with a special vice. Such a measure will provide the product with a stationary position, which will contribute to fast and high-quality cutting. The tool is mounted on the workpiece at an angle of 30-45 degrees, which minimizes noise and vibration when cutting, creating the thinnest cut possible.

Cutting the workpiece at right angles across the metal is carried out in exceptional cases. In this case, the evenness of the cut will be determined by the smallest angle of inclination.

For the convenience and safety of using a hacksaw, the master needs to take the correct posture. For good stability when cutting, the feet should be slightly apart. The hand with the hacksaw must be kept at a right angle. Care must be taken that the movements are calm and uniform. The first movement is made with little force, which allows the blade to enter the workpiece rather than sliding along the cut line.

The range of motion during the cut should be maximum, reaching the edges of the workpiece. The hacksaw arc must not be allowed to come into contact with the workpiece. Do not use just one section of the blade as it will quickly fail. The arc should be level, without tilting in different directions.

Important! Sharpening of hacksaws for wood and metal is not performed, since in such a tool the blades are equipped with small cutters, after which it is necessary to replace the consumable.

Features of the rotary miter box with a hacksaw

The swivel miter box with a hacksaw is represented by equipment consisting of a saw and an adjustable stand, with which you can adjust the cutting angle from 15 to 135 degrees. The miter box can be made of metal or plastic. The first option is used for cutting molded elements of small thickness, and the second - for a small amount of work.

The stand in the form of a miter box is used to give the instrument additional rigidity, while simultaneously acting as a limiter. A hacksaw with a blade equipped with small cutters can be 290-600 mm long.

When cutting a workpiece, the cutting element enters it at a certain angle, simultaneously in the vertical and horizontal plane. Thanks to such a two-plane tool, it is possible to form a bevel at the end of the workpiece of any configuration.

The attachment with a swivel miter box belongs to the best professional type hacksaws for wood and metal. It is advisable to use it for joinery work of increased complexity. The weight of the equipment is 2-4 kg. The price of a hacksaw for metal with a miter box is 2 thousand rubles.

To operate such a tool, the bed must be fixed on the working surface with self-tapping screws or a clamp. On the workpiece to be processed, markings should be applied indicating the cutting points. The product is fixed on the miter box so that the mark coincides with the slots on the plate. Then you need to set the degree of the cutting angle and fix the hacksaw so that it works in the same plane. After that, the workpiece is cut.

Rating of hand saws for wood and metal

A good model is the Bahco 208 hacksaw, which is a handle saw. It allows you to cut in hard-to-reach places, which is facilitated by the front loose end of the cutting element. The tool reaches dimensions 34x10x2.5 cm and weighs 260 g. Thanks to the fixing screws for the blade, a good cutting ability of the device is guaranteed.

The high-strength Sandflex blade is used as a cutting element, resulting in increased cutting accuracy.You can buy such a hacksaw for metal for 900 rubles.

In order not to be mistaken with the choice of hand saws for wood and metal, you need to familiarize yourself with the rating of these tools

The model TOPEX 10A 130 is popular. The tool has compact dimensions, which are 51.5x13x3.5 cm, and a low weight - 700 g. The ergonomic handle of the hacksaw is represented by a full-bodied rubberized product, which contributes to convenient operation. The cutting blade rotates, which makes it possible to cut at different angles. This also favors the high productivity of the tool, the cost of which reaches 500 rubles.

The Gross Pirahna 77604 hacksaw, which makes a clean and precise cut, is highly praised by experts and buyers. The blade is made of bimetal with HSS teeth. The blade length is 300 mm. Thanks to the rubberized handle, a comfortable grip and reliable holding of the hacksaw is provided during its operation.

The tool has dimensions of 40.5x15.5x3.5 cm, its weight reaches 900 g. The blade tension is created using a lever mechanism, which allows you to get an accurate, straight and accurate cut. The cutting element can be set at 45 or 90 degrees. The price of a hacksaw is 1.4 thousand rubles.

The metal hand saw is a must-have tool for the home craftsman. With the help of such a device, you can saw workpieces and parts from any materials. When choosing a tool, you should pay attention to the quality of the cutting blade, which ensures a clean and accurate cut.