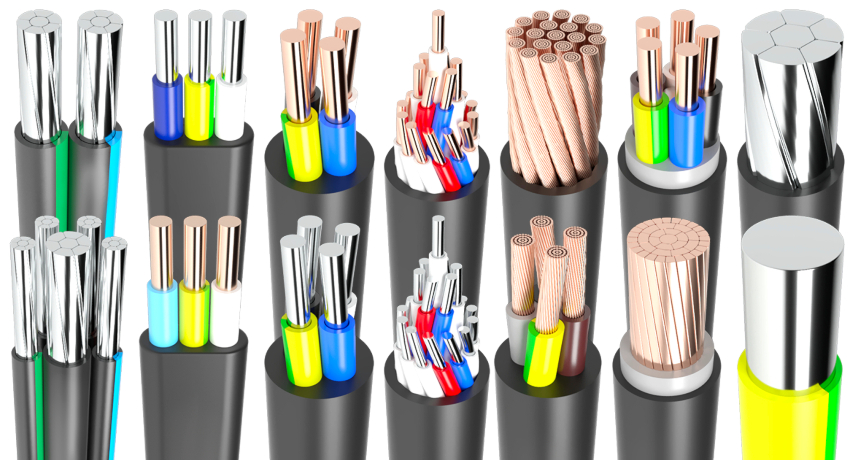

Any cable product has a conductor that is made of copper or aluminum. Since these materials are characterized by excellent efficiency and current conductivity, it is often necessary to connect them during installation and connection. How to connect copper and aluminum wires without making mistakes will be discussed later.

When moisture appears in the wired connection of copper and aluminum, electrolysis occurs, which can lead to burnout of aluminum or fire

Content [Hide]

- 1 Copper and aluminum wires: really incompatible

- 2 The impossible is possible, or how to connect copper and aluminum wire

- 2.1 How to connect copper and aluminum using terminal blocks

- 2.2 Features and secrets of using the crimping method

- 2.3 A few words about the rules for bolting wires

- 2.4 How to connect copper to aluminum by the threaded method

- 2.5 How to connect aluminum wire with aluminum one-piece method

- 2.6 How to connect aluminum wires using soldering

- 3 How to connect aluminum to copper wire outdoors: key process features

Copper and aluminum wires: really incompatible

To understand all the intricacies of the procedure, you should understand what lies in such a connection. After all, there are different opinions that it is absolutely impossible to connect copper wires with aluminum ones.

While some people doubt whether it is possible to connect copper and aluminum wires, others successfully do it

Like any other metals, with the participation of oxygen, aluminum and copper are oxidized. As a result, an oxide film appears on their surface. And if the copper cover almost does not interfere with the flow of electric current, then the oxide one is a serious barrier for this.

The wired connection of copper and aluminum, in spite of everything, will be the impetus for the interaction of metals. Aluminum is more active. This means that between the compounds, in the event of the appearance of moisture, the so-called electrolysis occurs - the transfer of aluminum ions to copper. As a result, the aluminum conductor loses its weight. Shells and voids appear in it, which also lend themselves to oxidation and only accelerate electrolysis.

The result is a nearly destroyed conductor that is made of aluminum. As its cross section decreases, the degree of current density increases. In turn, this provokes heating of the metal. There are only two options for the outcome of such a situation: either the aluminum burns out at the connection point, or a fire starts.

The impossible is possible, or how to connect copper and aluminum wire

While some doubt whether it is possible to connect aluminum wires with copper ones, many do it successfully.Moreover, there are a number of main generally accepted methods, thanks to which it is possible to eliminate contact between materials that act aggressively towards each other. Each of them requires separate attention.

The terminal block for connecting aluminum and copper wires can be equipped with both a clamping and a bolt mechanism

How to connect copper and aluminum using terminal blocks

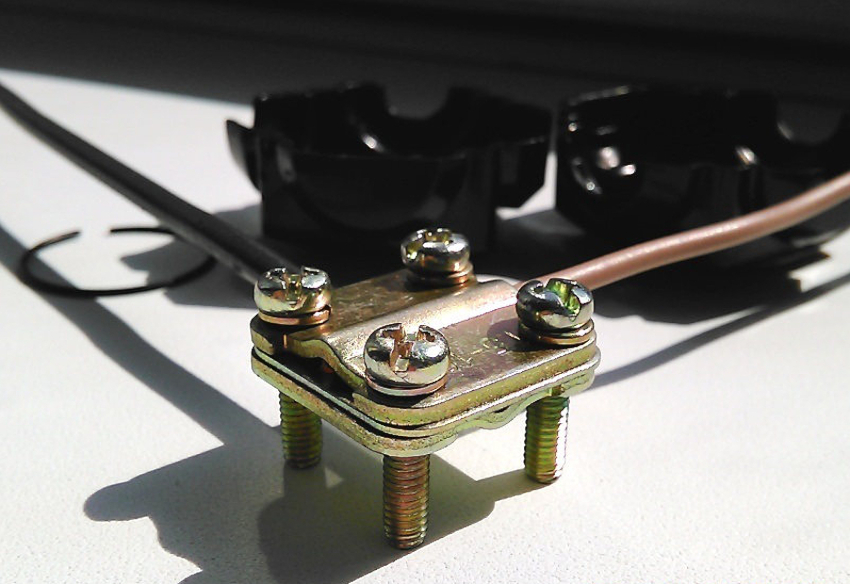

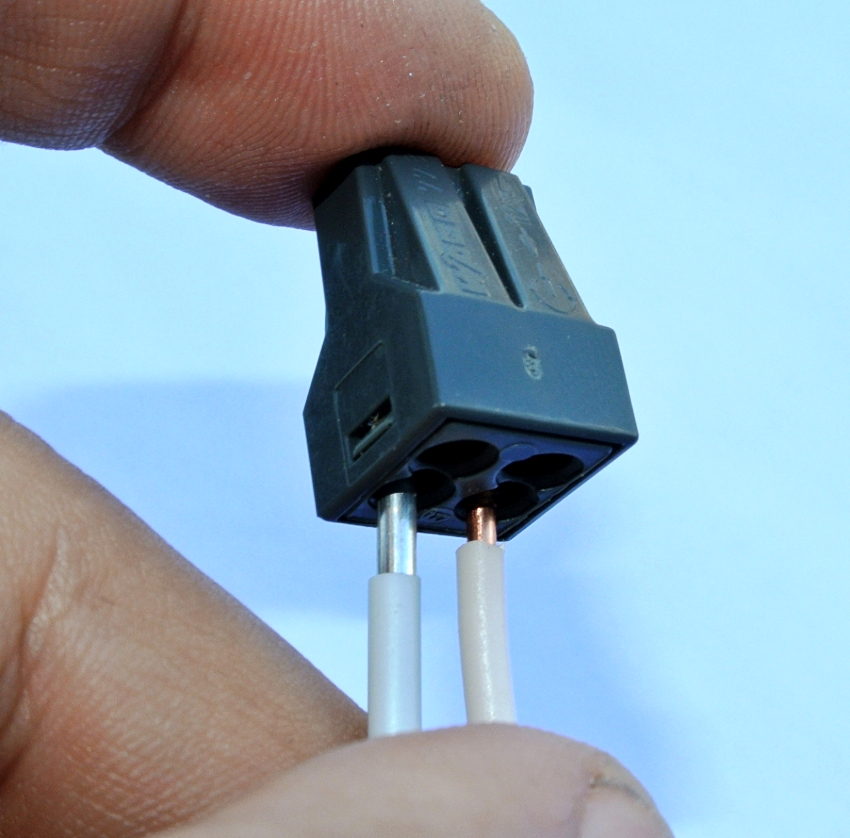

The terminal block for connecting wires can be equipped with a clamping or bolt mechanism. This design allows connection to two types of materials - aluminum and conductive. They are in contact with each other through a steel plate. It is made of a neutral material that does not tend to react with aluminum - often brass or tinned copper plates.

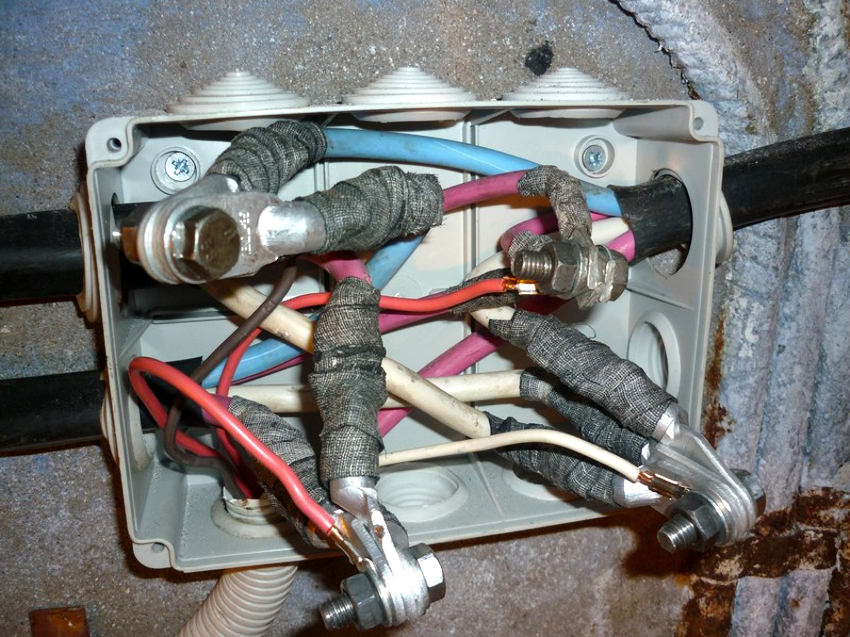

A terminal block containing a bolt clamp is more reliable and is used in low voltage power circuits. Often, such a clamp is performed using a "nut". It is a small junction box made of dielectric materials. The device received a similar name due to its shape. Inside it is a block of metal plates, through which contact is ensured between copper and aluminum wires.

Each of the above methods is a detachable connection. This means that, if necessary, you can repeatedly disconnect and reconnect them.

Note! Replacing the old wiring is recommended in any case. Copper has a load capacity that corresponds to the consumption of electrical devices. If it is not possible to perform a total replacement, it is done partially. Then the question arises of how to connect the wires correctly.

The most widely used wire terminal is capable of connecting up to eight conductors with different cross-sections, and can also be attached to a DIN rail using a special mounting adapter.

Features and secrets of using the crimping method

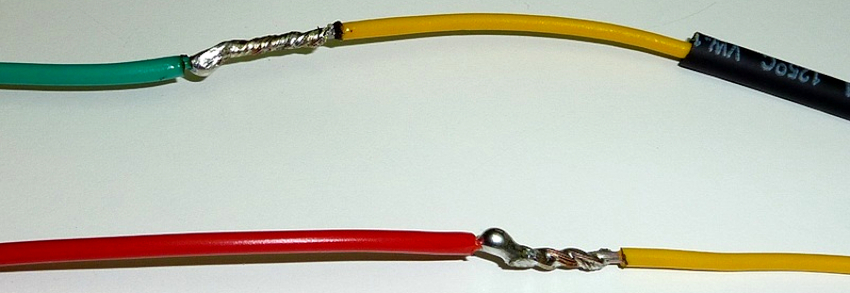

Sometimes in the process of installing and laying electrical wiring, it becomes necessary to obtain a high-quality wire connection. In this case, the connection of aluminum wires with copper wires is carried out by crimping using sleeves. Often, such a need arises at the stage of entering into electrical cabinets, switchgears, or when connecting a cable to an already installed unit, where there is no possibility of replacing copper with aluminum, and vice versa.

The presented type of connection of conductors is characterized by high cost, since it involves the use of specialized equipment and tools. At the same time, in the process of performing multiple such works, professionals often give preference to this particular method.

Important! It is not recommended to stack conductors made of copper and aluminum in parallel directions, in other words, overlapping. The fact is that in such a case, copper and aluminum are in direct contact. In addition, it is better to avoid using bare copper sleeves in combination with a cable made of aluminum.

A reliable connection of aluminum wires with copper wires can be obtained using the crimping method using sleeves

By crimping the wires with sleeves, a more durable and reliable contact is guaranteed. In a similar way, in production, aluminum and copper conductors are bonded even with powerful consumers.

To perform such work, you will need special aluminum-copper sleeves. If a manual hydraulic press is not available, they can be compressed using a standard hammer and aluminum pads.

It is interesting! Such compression is recommended to be used when performing crimping not only with sleeves, but also with tips. By the way, they can also be made half of aluminum and copper. This allows you to connect the aluminum wire to various devices with terminals or copper leads.

Often, aluminum-copper sleeves are used to connect cable cores that have a large cross-section. If the cross-section is insignificant, crimp a pair of conductors with a single sleeve. In this case, it is better to start the wires end-to-end - on both sides.

A few words about the rules for bolting wires

Often, when working with electrical wiring at home, a person who is not involved in specific work may wonder how to reliably connect aluminum and copper wires. Naturally, in such a situation, it makes no sense to rush to the market in order to purchase special tools. This is due to the fact that the work is one-off, but it is still necessary to complete it.

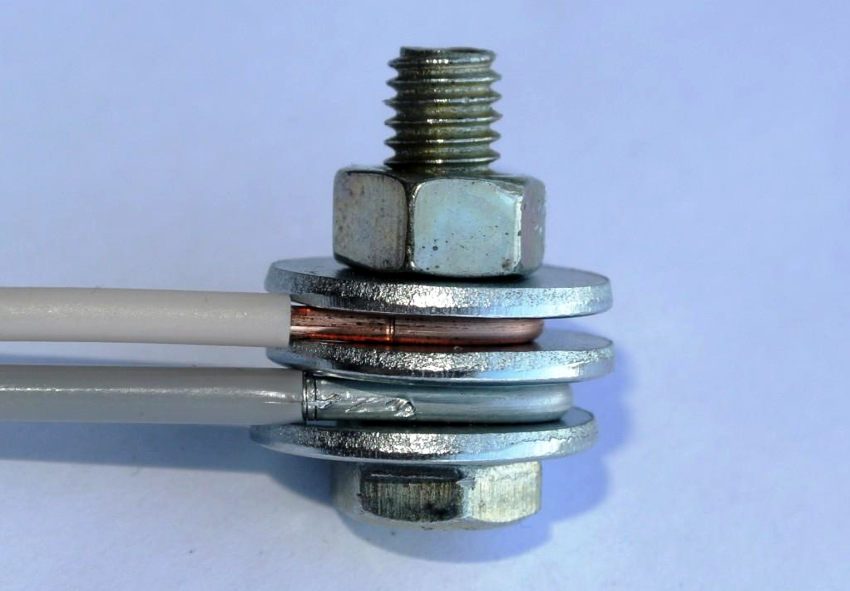

In such a case, an ordinary nut with a couple of washers and a simple bolt may well be used. In this method, the main thing is to separate the two metals that are aggressive towards each other with washers.

Note! If you decide to give preference to the bolted connection, the steel washer can be replaced with a part made of brass. If you have metal on hand, you can even cut it yourself. As for the version with a washer made of steel, it can be used only in those networks where the load is not too heavy.

The connection of copper wires with aluminum by bolting can be done in junction boxes. Without such structures, it is impossible to imagine wiring, and neither in houses, nor in individual apartments. Thus, with the help of a bolt, it is possible to quickly and easily solve the problem of how to connect a stranded and a solid copper wire.

When bolting, the rings formed from the wire must be turned in the direction of the nut. This is necessary in order to avoid unwinding the rings and increasing their diameter during tightening. On the contrary, this method will promote a tighter turn around the bolt.

In addition, there is a variant of using aluminum-copper washers and tips. There are several ways here:

- Crimp the aluminum cable with a ferrule and connect to a copper busbar.

- Crimp the cable made of aluminum with a standard aluminum ferrule and connect to the bus with this washer.

How to connect copper to aluminum by the threaded method

Connecting wires by means of nuts and screws, if correctly performed, is the most reliable solution and ensures proper contact throughout the entire life of the wiring. The answer to the question of whether it is possible to connect copper and aluminum wires of various types by means of a threaded connection will be an unequivocal "yes". Using a threaded connection, you can work with thick, solid, thin, as well as stranded wires. The main thing is to prevent direct contact of wires made of aluminum and copper.

Before connecting the wires with a threaded method, you need to strip until the metal shine and form rings

Before connecting the electrical wires with a threaded method, preparation has to be carried out: remove the insulation from the conductors to a length that is equal to four times the diameter of the screw, in the case of oxidation of the cores, strip them until the metal shines, and also form rings.

After that, the screw is ringed in the following order:

- spring washer;

- simple washer;

- ring of one conductor;

- simple washer;

- ring of another conductor;

- washer;

- nut.

When screwing into the screw nut, the whole package is pulled together until the spring washer is straightened.

For conductors in which the core diameter does not exceed 2 mm, an M4 screw will suffice. If the copper wire is stranded, first of all, it is necessary to trough it by means of solder.

How to connect aluminum wire with aluminum one-piece method

The one-piece connection is endowed with all the advantages of a threaded one. The difference is only in some points:

- the ability to disassemble and reassemble connections without breaking the rivet;

- the need for the presence of special devices for riveting.

Today rivets have found wide application for permanent connections of thin-walled structural elements in the process of creating partitions. Efficiency, low cost and durability are the main advantages of the presented type of one-piece connection.

The essence of the functioning of the riveter is quite simple. It retracts and cuts steel rods threaded through a tubular head rivet made of aluminum. The rods are thickened, and as the rivet is pulled into the tube, it expands.

With the help of a riveter, you can make not only one-piece connections of thin-walled elements, but also reliably connect electrical wires

Note! There are rivets of various types, diameters and lengths. Therefore, everyone can choose the best option for performing personal tasks.

To connect the conductors with a rivet, you need to prepare them in the same way as for a threaded connection. The diameter of the rings should be slightly larger than the diameter of the rivet. The optimal size is 4 millimeters. Parts are put on the rivet in the following order:

- aluminum conductor;

- spring washer;

- copper conductor;

- flat washer.

Then the steel rod is inserted into the riveter and its handles are pressed until it snaps into place. This sound indicates that excess steel bars have been cut. That's all, the connection is complete.

Related article:

Wiring connection in the wiring junction box

Varieties and methods of installing junction boxes. How to install yourself.

The degree of reliability of both one and the second presented type of rivet connection is quite high. This connection method can be successfully used in order to heal damaged areas in the process of repairing conductors in the wall. However, it is imperative to ensure excellent insulation of bare joints.

Since rivets exist of various types, diameters and lengths, everyone can choose the appropriate option.

How to connect aluminum wires using soldering

In the case of a large conductor cross-section (when mass is more important than strength), it will be rational to give preference to aluminum. The cross-sectional area of a wire made of aluminum will be several times larger in comparison with a copper one, and the aluminum part will still be twice as light as the copper one. If you ask people about how to connect copper wires to each other, many will answer that it is better to do this using soldering.

It is possible to solder wires made of aluminum in a junction box using a gas torch or a soldering iron. The difficulty in using a soldering iron is that it is almost impossible to accurately heat to the desired temperature. And in the case of aluminum, overheating is just as unacceptable as insufficient heating.

Important! The metal is characterized by significant thermal conductivity, and it can melt over a wide area from the soldering point.

Therefore, before connecting the aluminum wires to each other, so as not to heat up, it is better to arm yourself with a gas burner. With its help, it is easier to adjust the heating temperature, but it will take a long time to prepare the surface to use it. Nevertheless, it is better to give preference to the burner if it is necessary to solder massive parts. Be that as it may, soldering aluminum wires involves preparing them.

The difficulty of the brazing process is that aluminum is characterized by low melting properties, therefore, in the case of careless heating, it can melt. The essence of another factor, due to which the soldering process becomes more complicated, is reduced to the rapid oxidation of aluminum in air.

Although the oxide coating on the surface is a reliable protection of aluminum from the effects of negative external conditions, it simultaneously inhibits the adhesion of the material with the solder, so it must be removed without fail.

Note! It is not possible to remove oxide deposits mechanically. The material is immediately oxidized and covered with film again. You can get rid of it only mechanically by covering the surface with an oil layer.

The oil option is completely inconvenient at home, and is also characterized by laboriousness. Previously, the oil must be calcined to a mark of 200 degrees in order to rid it of the oxygen present in it.

Thus, in anticipation of soldering, the ends of aluminum conductors should be processed. The use of rosin or many other fluxes will not be effective due to the high degree of chemical stability of the oxide coating. It does not dissolve even when organic acid is applied.

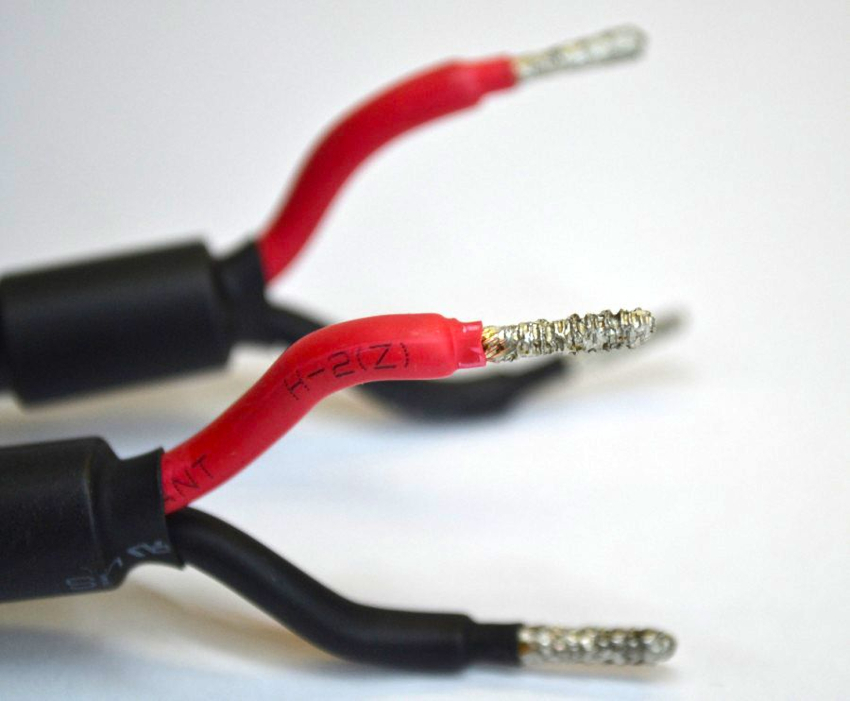

Note! In order to carry out the tinning of wires, fluxes specially designed for this purpose and the mechanical method should be used simultaneously.

Naturally, a similar procedure should be performed before twisting the wires. Otherwise, it will not work to clean the entire surface of the wire. Only the ends that have been tinned can be twisted together and then soldered.

Wires with multiple cores should only be soldered using a special flux, as they are almost impossible to machine mechanically. A feature of soldering technology is that each of the wires must first be thoroughly processed using flux.

To do this, you will have to unwind and fluff the bunch. After the processing is completed, each of the thin wires of the core will need to be covered with a layer of solder and twisted into a bundle. After that, several ends are twisted and soldered.

Important! Situations can often arise when it is required to connect wires from different metals. It should be noted here that brazing aluminum with copper is not possible.

The whole problem lies in aluminum. Due to its chemical and physical properties, aluminum cannot be soldered to another metal. If you decide to solder copper and aluminum, using a solder that is neutral to both metals, the differing expansion coefficient of temperature will quickly destroy the contact. This is due to the fact that during the passage of current through the conductor, it will necessarily heat up, and after disconnection it will cool down, and nothing can be done about it.

Studying the question of how to connect aluminum wires to each other when laying power wiring, it becomes clear that a standard soldering iron and sandpaper will not cope here.Therefore, before connecting copper wires to each other, you need to arm yourself with knowledge of the basic postulates of welding.

However, when it comes to connecting wires that are made of different metals, it is better to discard the idea of welding right away. This is due to the difference in temperature required to melt the metals. And such a procedure will not protect at all from destructive electrolysis.

How to connect aluminum to copper wire outdoors: key process features

In the process of installing cable lines in the street, each of the connecting elements is influenced by negative environmental factors. Snow, rain, fog, icing will definitely not contribute to a high quality connection.

In this regard, to carry out such work, an extremely sealed structure will be required. Moreover, it should be characterized by resistance to low temperatures and ultraviolet rays.

Having decided to connect on the street, you should arm yourself with the knowledge of how to connect a self-supporting insulated wire cable with a copper wire. After all, it is through this operation that you can connect copper and aluminum wires in an open area.

How to connect a self-supporting insulated wire and a copper wire: features of each option

Depending on the location of the metering board, the options for connecting the self-supporting insulated wire may vary.

If the metering board is located on the line support, the connection is made by means of a solid conductor. Within the shield, it is directly connected to the machine. To connect the conductors to the line, it is recommended to use a standard piercing clamp, which is specially designed for SIP lines.

It is interesting! Piercing clamps are designed to connect taps to the trunk line. Such specimens can be used to connect lines, the cross section of which is from 16 to 120 mm2, and the section of the tap is in the range from 6 to 50 mm2. In this case, both a self-supporting insulated wire and a standard cable made of copper can serve as a tap.

The main clamping elements are two sharp-toothed plates made of steel. In the case of tightening the mounting bolts, they come closer together and at the moment of piercing the insulation of the wires, they create reliable contact and tightness of the attachment point. The bolts are tightened until they break, which is designed for a certain compressive force. In this case, the design is disposable.

If it is decided to connect from the metering board to the house with the help of self-supporting insulated wire, it is also impossible to do without standard fittings. The best option would be to insert the wire into the junction box and connect it to the machine in the switchboard. In this case, there is no need to couple it to the cable.

Note! A special clamp should be used to connect the self-supporting insulated wire to bare (uninsulated) wires. It should have no sharp teeth on the side of the bare wire attachment.

If the metering board is placed on the wall of the house, the tap, which is connected to the main line by means of a clamp, is inserted into the metering board and connected to the machine. If the SIP performs the role of the tap-off conductor, so-called anchor clamps are mounted on the support line and on the wall, which secure the wires.

It may be necessary to connect a copper cable with a self-supporting insulated wire wire if the site has several buildings and power distribution is carried out through them through a self-supporting insulated wire. In such a situation, the installation can be performed using the above method, using a ram or piercing type clamp.

Connecting Copper and Aluminum Wires: A Few Quick Tips

And finally, a couple of tips for you. By taking them into account, you can avoid mistakes with adverse consequences.

First of all, in order to strip the conductors, it is better to abandon the use of side cutters, pliers or other instruments with a similar principle of operation. Cutting the insulation without touching the wire body will require significant experience. As practice shows, often the integrity of the wires is still violated.

The fact is that aluminum is a ductile metal that does not tolerate kinks, especially if the surface cannot boast of integrity. Stripping should be done with a sharp knife - by moving along the conductor. This process is similar to sharpening pencils.

To perform tinning of copper conductors, you cannot use fluxes containing acids, such as hydrochloric acid, zinc chloride, etc. Even a high-quality cleaning of the connection for a certain time will not save it from the corrosion process.

Note! To exclude the ingress of water into the joints of metals, you can use a special paste. Such a composition will prevent the penetration of not only moisture, but also oxygen. The result is quite negligible oxidation of aluminum. And due to the lack of moisture at the junction point, the most destructive process, electrolysis, does not develop.

If we are talking about a product such as an aluminum stranded cable, it must be installed before installation in order to achieve a monolithic effect. The only exceptions are spring-type clamps and terminal blocks, which are equipped with a pressure plate.

All kinds of additional parts: nuts, washers and bolts - must be made of non-galvanized metal. The bottom line is that the potential difference between copper and zinc is much higher than the difference between a copper-aluminum pair. By the way, for the same reason, you do not need to buy too cheap pads produced by an unknown company. As practice has shown, metal parts in such pads have exactly a galvanized coating.

Contrary to popular advice, once copper and aluminum wires are connected, they should not be treated with water-repellent compounds. It is difficult to remove oil for cars only from the skin. Under the influence of air, sun and freezing temperatures, the protective coating will be destroyed much faster than it was intended. In addition, some lubricants initially contain several percent of water.

So, now you know for sure that you can still connect a copper wire to an aluminum one, and this is done quite quickly and easily. The article presents the main ways to accomplish this task both indoors and outdoors.

However, there is no definite answer to the question of how to connect copper wires with aluminum ones. It all depends directly on the conditions and devices that are available nearby.

We hope this article helped you figure out how to properly connect copper and aluminum wires. If you still have questions about how to connect, the video below will help you deal with all the unclear points.