From this article you can find out what technical characteristics a wood milling machine used in home workshops has. The text describes the main varieties of this tool, taking into account its functionality and other parameters. Using this information, you can select high-quality workshop equipment that will meet all the requirements and will be able to perform the necessary operations.

Milling is the most popular process when working with wood, which is carried out using a milling machine

Content [Hide]

- 1 Wood milling machine: general information about the tool

- 2 Which is better to buy a wood milling machine: types of structures and characteristics

- 2.1 Features of the use of a CNC milling machine for wood

- 2.2 Technical characteristics of CNC milling machines for wood

- 2.3 Features of milling and copying machines for wood

- 2.4 Specificity of CNC turning and milling machines for wood

- 2.5 Characteristics of CNC milling and engraving machines for wood

- 2.6 Features of hand held wood router for home workshop

- 2.7 Characteristics of desktop CNC milling machines for wood

- 2.8 Specificity of 3D CNC Wood Milling Machines

- 3 Purchase of CNC milling machines for wood: prices and recommendations

Wood milling machine: general information about the tool

Milling machines are a popular category of joinery equipment. They are used for milling relief parts and profiles, cutting and processing blanks in order to give them the required configuration. With the help of these machines for wood, it is very convenient to make grooves and process the edge part of products, cut thorns and even make small interior elements, such as skirting boards.

Using additional accessories, you can significantly expand the functionality of the milling machine to produce parts with complex configurations. In most cases, such equipment is installed in private workshops, as well as in small industries. Desktop versions of the instrument are used by craftsmen who work from home.

Note! Before you buy a CNC wood milling machine, be sure to check for a certificate. This document guarantees the compliance of the instrument with all the standards established by the state, as well as the safety of its use.

The device of a milling machine for wood for a home workshop

Most milling machines have the same structure. The standard construction of a woodworking tool consists of:

- milling table;

- caliper;

With the help of a router, it is convenient to select grooves and process the edges of products, as well as produce interior elements such as skirting boards

- bed;

- spindle for a CNC milling machine;

- cutting element.

A carriage is included as an option on some models. This element allows you to process workpieces at different angles.

The bed of a wood router is a solid piece that is stable. It is not affected by vibrations and vibrations that arise during the operation of the tool. The shaft is mounted on a support, the upper part of which is brought out through a hole in the table. If the need arises, you can always adjust the height of this element, adjusting it to the needs of the master. A spindle with a plug-in design and a cutting part are installed on top of the part. The type of cutting element is selected taking into account the task at hand.

The following can be used as a cutting part:

- cutters;

- disks;

According to government requirements, all woodworking milling devices are required to be certified, which guarantees their safety during operation.

- knives;

- drilling and cutting elements for wood milling.

The higher the rotational speed of the spindle, the higher the quality of material processing. This nuance should be taken into account when performing operations that need precision. The tool has a special structure that provides the ability to safely and quickly change the cutting element.

If the milling needs to be done in a straight line, you cannot do without using a guide bar with a movable structure. Special grooves are provided for fixing the tool stops. Many modern models of devices, regardless of whether the carriage is included in the package, are supplemented with an industrial vacuum cleaner. It effectively and quickly removes chips and dust from the work area.

Which is better to buy a wood milling machine: types of structures and characteristics

The structure of the milling machine varies depending on the type of construction and model. Therefore, the master has the opportunity to choose a tool that will meet his needs.

The most popular types of designs:

- wood turning and milling machine;

- CNC router;

- manual unit;

- copying;

- desktop;

- household router;

- vertical;

- horizontal;

- double-sided, etc.

Each of these devices has specific functions and characteristics. Therefore, before buying a manual wood milling machine or other type of unit, it is advisable to familiarize yourself with its capabilities in more detail.

Any kind of wood milling machine is quite difficult to operate and requires special care in its work.

Note! Before starting work, you need to make sure that the piece of wood is securely fastened. Otherwise, the cutter will forcefully throw it aside.

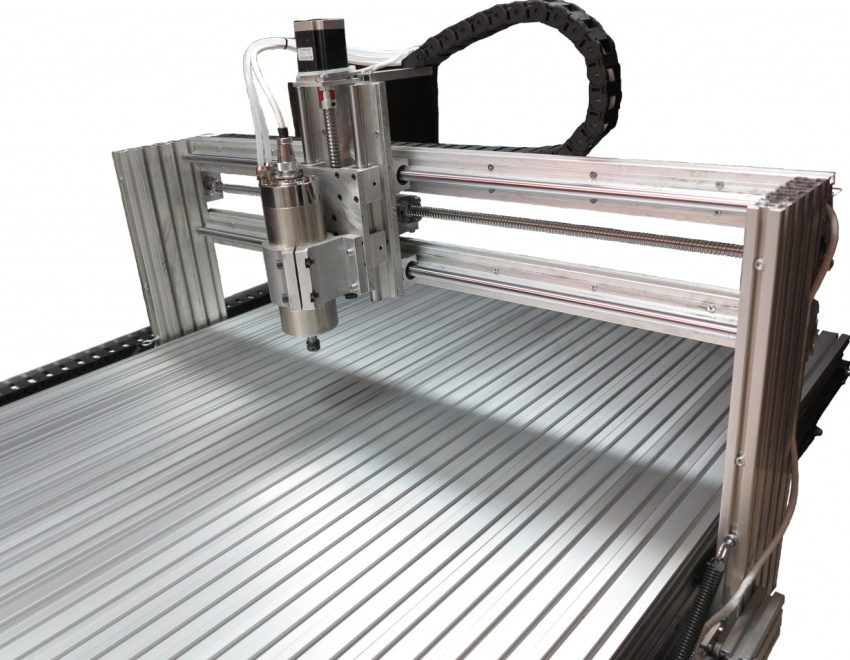

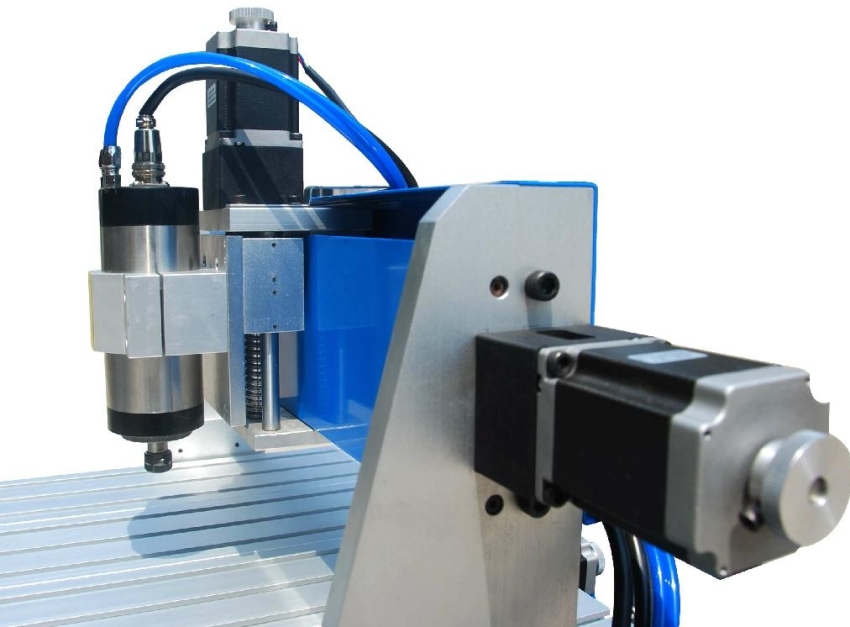

Features of the use of a CNC milling machine for wood

CNC devices are considered to be relatively new equipment. Such universal milling machines are additionally equipped with electronics. The design contains a microprocessor, which greatly simplifies the process of processing wooden parts and improves its quality.

Work on a CNC machine is carried out in the following order:

- With the help of specialized software, a program is compiled.

- A piece of wood is attached to the work table.

- The program is entered and a test run is performed.

- In the established mode, the processing of a wooden blank is carried out.

- If the need arises, the program is corrected.

The described process requires minimal operator involvement. This is the main advantage of mini CNC milling machines used in home workshops. Large units are used in production. They perform complex technological tasks. Mills of this type are console and non-console.

In cantilever machines, the block with the cutting element is fixed and does not change its position during processing. In this case, the working table moves, which moves in the transverse and longitudinal directions. This type of milling cutter is mainly used for processing metal parts, since the size of the workpieces is limited.

In non-cantilever models, the cutter displacement is provided by a carriage with transverse and longitudinal guides. In this case, the processing unit can be given both vertical and horizontal position, depending on the tasks.

Note! To buy a CNC milling machine that has optimal parameters for work, you must definitely study the technical characteristics of the model. In some cases, the subsequent modernization of the tool without loss of performance will not work.

The capabilities of the mini-unit with CNC are quite wide - it can be used for milling the formation of embossed surfaces on wood products

Technical characteristics of CNC milling machines for wood

The most common are consoleless units. Most often they are used for processing flat wood blanks.

When choosing equipment for a workshop, first of all, you need to pay attention to the following characteristics:

- allowable size of workpieces (height, length, width of the workpiece);

- tool speed in idle mode;

- number of spindle revolutions;

- spindle cooling performance (if this function is available);

- type of CNC (presence or absence of the ability to replace or upgrade the unit).

In addition, before buying a tool, it is worthwhile to indicate in advance the set of functions necessary for work. For this, the parameters of the control unit are analyzed.

Depending on the functionality, the following types of equipment are distinguished:

- Position control machines - the cutter is placed on the surface of the part in a specific position.

- Contour controlled milling cutters - the program algorithm includes the order according to which the working head of the tool moves within the specified path.

- Universal milling machines - the program includes positional and contouring functions, and can additionally monitor the position of the cutter and the parameters of the operation that is being performed at the moment (degree of processing, depth, etc.).

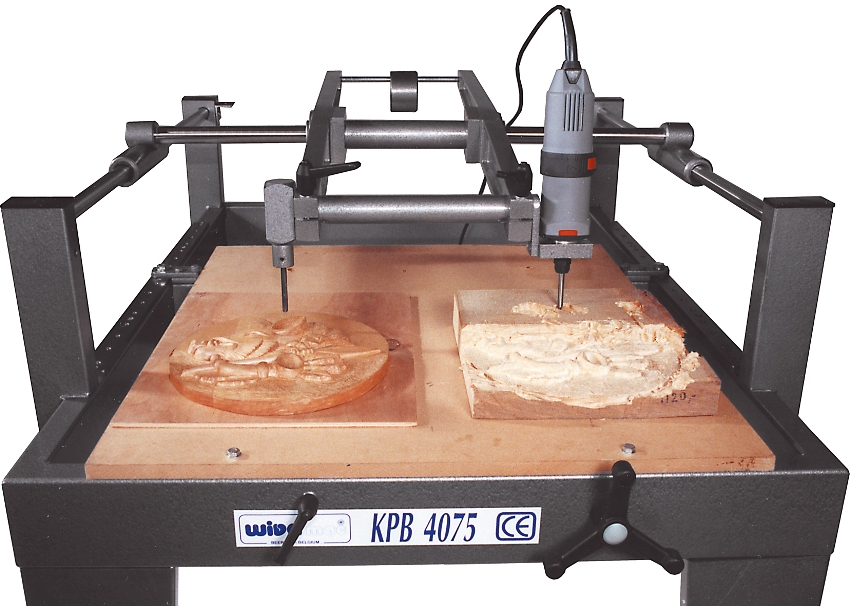

Features of milling and copying machines for wood

Copying equipment is designed to perform work of a high level of complexity. Such wood machines are used for processing workpieces with a large number of carved patterns and small parts that need precise and accurate execution.

The identity of the decorative mini-elements is ensured through the use of special templates. They can be made of wood or plastic. The master fixes the workpiece with a vacuum method, after which the tool copies the contour lines of the template. The result is identical parts with complex patterns. With the help of a router, you can make volumetric and contour copying. These machines are compact, robust and durable.

On a copy-milling machine for wood, you can perform complex work, in which there are many different patterns and details

Milling and copying equipment is ideal for the following operations:

- creation of ornaments and patterns;

- application of inscriptions;

- engraving of shaped profiles;

- making complex patterns with edges located in different planes.

Related article:

Do-it-yourself wood milling machine: step-by-step manufacturing technology

The device and diagram of the tool, drawings and step-by-step instructions for the manufacture of an electrical appliance and a table for its installation.

The classification of machines includes the following types of equipment:

- with a pantograph (for processing workpieces in 2-3 dimensions);

- universal (equipped with a pantograph and a rotary arm);

- with several spindles (characterized by an accelerated processing process);

- with hydraulic, electrical or mechanical feed;

- photocopiers.

Milling and copying machines allow the production of parts in large quantities, while ensuring a high speed of processing and manufacturing of each element

Helpful advice! When making homemade copy structures, it is imperative to take into account the size of the blanks that will be processed on the machine. In the process of milling large parts, serious vibrations occur, so the equipment must have a massive structure that can drown them. Particular attention should be paid to the reliability of the steering axes. It is on them that the main loads will act.

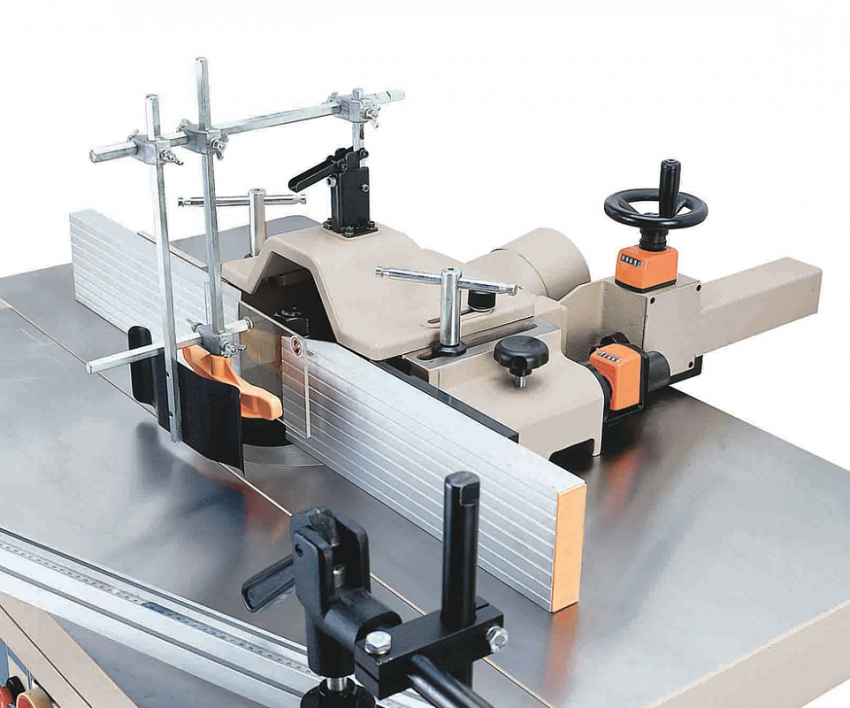

Specificity of CNC turning and milling machines for wood

Turning and milling equipment is designed to perform a wide range of works. The design of such machines consists of two parts. The milling section of the tool is usually placed vertically and turning - horizontally. In turn, the last of them plays the role of a kind of base, where the tailstock, bed and spindle are located. Such structures are used to perform various tasks, from the shaped processing of wooden blanks to the boring of holes.

Consumers have the opportunity to buy turning and milling machines equipped with additional functional equipment. This significantly increases the efficiency and quality of processing operations. Such additions include bed extensions. Thanks to these elements, it becomes possible to process large-sized workpieces.

The multifunctional wood milling and turning machine has a large comfortable table that allows you to work even with large workpieces

Turning and milling equipment is useful for those craftsmen who plan to open a small furniture production or process wood products. The tool is capable of performing curvilinear shaped cutting. There are professional and semi-professional models on sale. Modern units can process parts up to 75 cm long. With additional equipment, these figures can be increased. The processing diameter can be up to 22 cm.

Characteristics of CNC milling and engraving machines for wood

The milling and engraving type of equipment is used for curved cutting, engraving and wood carving. Using this tool, you can create products of a very complex configuration, with a large number of details, as well as inscriptions and relief drawings.

The capabilities of CNC milling and engraving machines will be useful for the manufacture of the following objects:

- cabinet furniture;

- interior decor and furnishings;

- stairs, facades and door structures;

- onlays with a figured shape, decorated with deep or through carving;

- molds for casting;

- souvenirs, etc.

When choosing milling and engraving equipment, it is advisable to pay attention to models in which the bed is made of cast iron or other heavy alloys.The best option would be one that has a sufficient size of the working area, which will allow processing the workpiece in one setup. The less you have to change the position of the wooden part, the better.

Helpful advice! To quickly change the position of the workpiece, experts recommend buying a tool with a servo motor. In turn, stepper motors are much more economical.

Features of hand held wood router for home workshop

Small handheld units are designed for small jobs in the home. Such machines are not suitable for large-scale production, because their operation does not imply regular processing of massive workpieces. A hand tool will do a good job of forming small grooves for the subsequent connection of individual elements of any structure.

In addition, hand routers are used for the manufacture of screeds and decorative elements of furniture. With the help of the tool, the operator will be able to perform almost jewelry work without using a bulky table.

Hand tools are much cheaper than stationary models, largely due to the fact that they have a simple design and are equipped with simple parts.

The tool is used to perform the following tasks:

- installation of window structures;

- door installation;

- creation of groove joints and locks;

- turning planks.

Despite the limitations, there are models on sale that have advanced functionality, for example, Makita. The price of manual milling machines for wood of this brand is quite high (180,000-23,000 rubles). Such models can be used not only for wood processing, but also for plastic and metal.

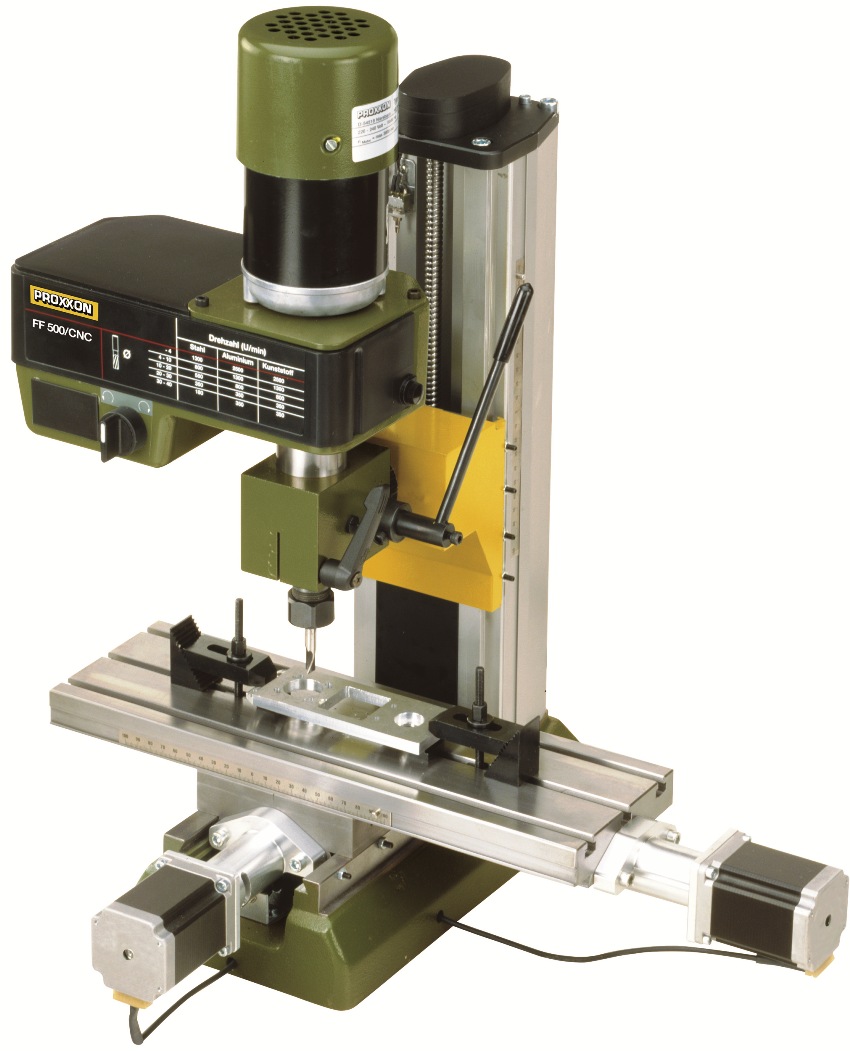

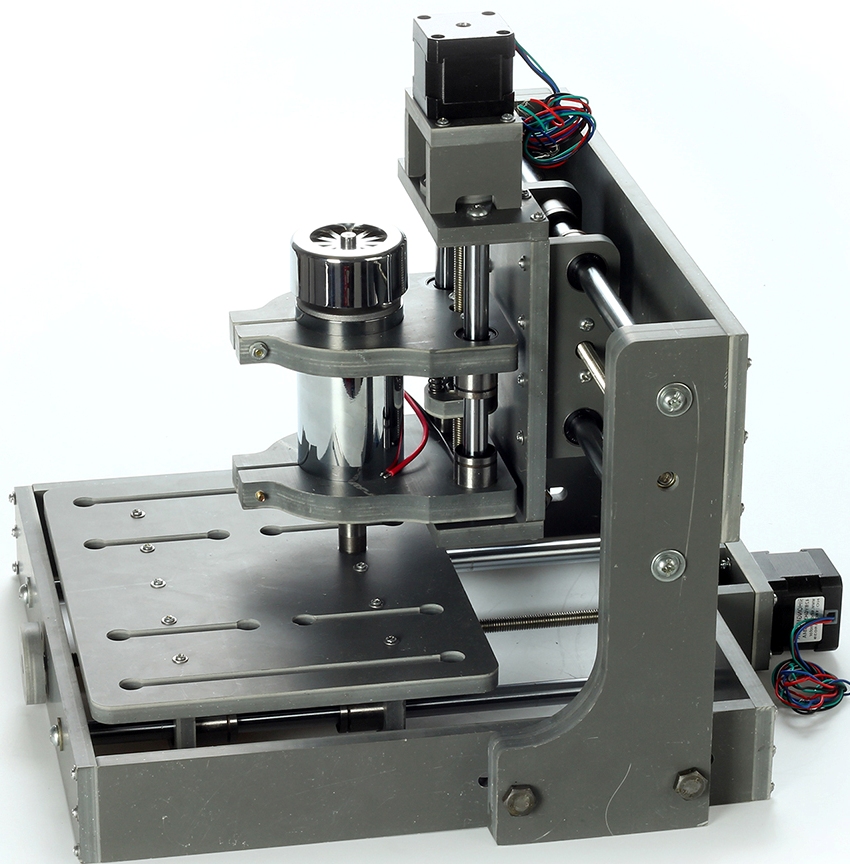

Characteristics of desktop CNC milling machines for wood

The benchtop equipment has almost the same capabilities as a manual wood router, but its power is significantly higher. Such machines have a simple structural structure and a convenient operating system. Due to their compact size, as well as the presence of a fairly large list of functions, bench-type routers are widely used in home workshops.

The table router can be installed on any surface with a vertical position. Its design is equipped with a small work table.

Small dimensions and weight of desktop CNC milling machines allow their use in small-scale production and even for domestic use at home

Advantages of desktop wood milling machines:

- Mobile design.

- Low price.

- Simple operation system.

With the help of this equipment boring, drilling and milling of wood is carried out.

The desktop tool is suitable for the following tasks:

- creation of slopes, miniature elements of furniture structures and other decorative details;

- the formation of embossed patterns;

- making grooves;

- sawing wood blanks;

- drilling, etc.

All this is made possible by a small but heavier shaft. Desktop equipment can have both manual control and CNC.

Important! The tool can only be traversed in the opposite direction to the cutter path. Failure to follow this rule could result in injury.

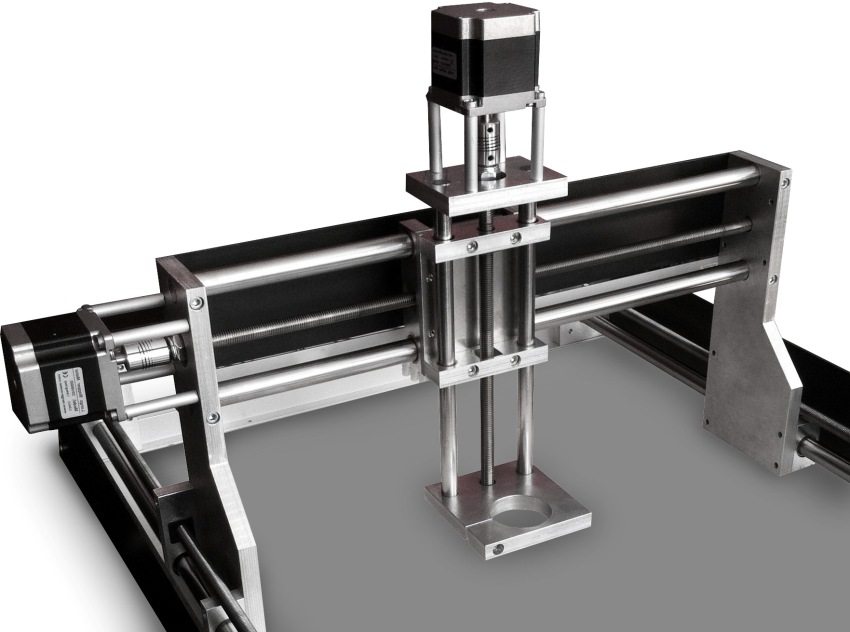

Specificity of milling machines 3D CNC woodworking

Large and small furniture factories, as well as woodworking enterprises are equipped with milling equipment with 3D function. This tool is used to make unique products, exclusive furniture and decorative elements, high-precision wood carving.

Most often, 3D CNC milling machines for wood are used for processing wood on an industrial scale.The computer programs on the basis of which the CNC functions simplify control and increase its accuracy. Due to the special structure of the structure, using this tool, you can create not only single products, but also start serial production.

Benefits of routers:

- high functionality that allows you to perform a wide range of production tasks;

- reliability and durability;

- high level of productivity;

- wide scope of application;

- high precision and quality of processing, which is carried out in three planes;

- simple system of operation and maintenance;

- robust construction.

The function of processing wood in 3D mode allows you to perform the following operations:

- finishing workpieces, in particular, the production of grooves and through grooves, as well as window structures;

- face milling for large area workpieces;

- shaped processing of workpieces, allowing to obtain profiled grooves with a complex configuration in window and furniture industries.

Purchase of CNC milling machines for wood: prices and recommendations

First, you should decide for what work the tool will be used. Based on this, the engine power should be selected. For household use and home repairs, a light-duty handheld router is suitable. If the tool will be used in areas such as furniture assembly or construction, it is worth considering purchasing a higher class machine.

Average prices for wood milling machines:

| Tool type | price, rub. |

| Manual | 2500-94500 |

| Desktop | 46000-247000 |

| Turning and milling | 113500-159900 |

| Milling and copying | 186900-2280000 |

| Milling and engraving | 170000-1710000 |

| 3D machine | 104900-2578900 |

When choosing a tool, you should also take care of safety. There must be a lock on the power switch to prevent accidental activation. If this protection is absent in the design, you will have to constantly monitor the machine to avoid injury. Collets must be made of hardened steel. In quality models, the outsole has a cast metal construction. In addition, they are necessarily equipped with fine adjustment mechanisms and dust extraction. It is desirable that the table is adjustable in height, and also has reliable fasteners.

Choosing the best CNC machine can be difficult even for professionals, if they do not follow the latest developments in the tool market, the range of which is constantly expanding and improving.

On sale you can find hundreds of models in different price segments. Do not pay attention to cheap milling cutters from unknown manufacturers. Such trusted companies as Makita, Bosch, Interskol produce reliable equipment that will last for more than one year. In the event of a breakdown, spare parts for repair are always available in service centers and stores, because well-known manufacturers take care of their reputation and provide warranty service for the tool.