Fiber cement panels for the exterior of the house have been used in modern construction relatively recently. Their popularity is won by their convenience and ease of use. Their task is to perform all functions of protecting the house from temperature extremes and the effects of adverse weather conditions. Among other things, such panels are an element of decorative finishing of the facade of any private building.

Fiber cement panels perform not only a decorative role, they provide heat and moisture insulation of the building

Content [Hide]

Fiber cement panels: composition and properties

Facade panels of this type belong to durable types of finishing building materials. The basis of such slabs is a particularly durable cement composition with the addition of reinforcing substances. The additive is only 10% and can be made of fiberglass, cellulose or other mineral components. However, even such a small amount is sufficient to provide products with high strength, some flexibility and resistance to external influences. Outside, the panels are covered with additional layers of acrylic or other compounds.

For the first time, fiber cement panels for the exterior of a house began to be used in Japan, therefore, even now they are called Japanese. Russian enterprises have long established the production of such products, which are distinguished by excellent texture options and a variety of color palettes. Cement panels are suitable for furnishing facades any public and private buildings. Due to their flexibility, they can be used for cladding complex architectural structures. They are quite convenient for revealing dilapidated buildings, since this method of facade decoration does not require preliminary cleaning of old surfaces or leveling.

Features of the production of fiber cement slabs

Facade panels made of a material such as fiber cement using an autoclave and a press. High-quality products are obtained by pressing under high pressure. Its indicator should exceed 600 N / cm². The autoclave temperature ranges from 165 to 175 ºС. Under these conditions of production, the structure of the panels is sufficiently uniform and stable.

Exterior decoration of the house fiber cement panels

The last step in the manufacturing process is painting. For this, various types of paint are used: textured or regular smooth. With the help of texture paint, panels are made that imitate wild or artificial stone. To protect the finished product from the effects of harmful sunlight and various precipitation, they are covered with a special protective compound. And for a greater resemblance to stone slabs, sprinkle with crumbs.

Useful advice! When choosing fiber cement plates, the total weight of the future structure should be calculated. Heavy panels can put quite a lot of stress on the walls as well as the foundation of the building.

Fiber cement panels for exterior home decoration: pros and cons

Any finishing material has its positive qualities and some disadvantages. The advantages of fiber cement boards include:

- extended service life (approximately 20 years);

- environmental friendliness;

- resistance to adverse conditions;

- powerful heat and sound insulation properties;

- increased fire resistance.

Due to such a large number of positive qualities, the use of fiber cement panels for the exterior of the house is becoming more common. But such material also has disadvantages and disadvantages. A rather large mass can be attributed to them. The weight of an ordinary panel, depending on the thickness of the manufactured products, varies from 10 to 14 kg per square meter. Working with such heavy-duty slabs alone is quite difficult.

Another disadvantage is the high moisture absorption rate. Such a material can absorb up to 10% of water, as a result, slight deformation may occur, which does not affect the strength in any way. The disadvantages can also be attributed to the impossibility of cutting panels with an ordinary knife or hacksaw. For high-quality sawing, you will definitely need a power tool.

Useful advice! Slabs can be cut using a conventional grinder, using a special stone for concrete.

The main features of the installation of fiber cement panels

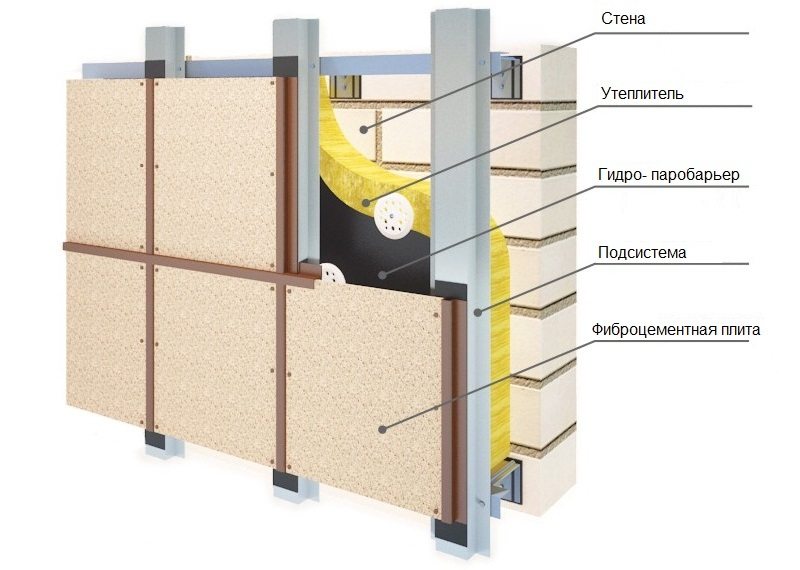

Installation of fiber cement panels for the exterior of the house is carried out on the principle of a ventilated facade. The hinged method of installation allows laying mineral insulation under the external finish for greater thermal insulation of the interior. The frame for such slabs must meet a number of requirements.

Requirements for the arrangement of the frame

- The frame should be made of special profiles, from which they equip a kind of crate.

- The base for fiber cement panels is securely attached to the wall of the house. To accomplish this task, special fasteners (brackets) are used, which are additionally separated from the wall by pieces of cushioning material.

- The brackets are mounted with a certain pitch. Vertical - 100 cm, horizontal - 60 cm.

- If additional insulation of the house is required, then the insulation boards are laid in the gaps between the frame profiles. It is additionally attached to the wall using "fungi".

Installation of fiber cement panels

Installation of fiber cement panels for the exterior of the house also has its own characteristics. To prevent the foundation from getting wet, installation is performed plinth with the arrangement of the low tide. Its height is usually 50-100 cm from the ground or existing blind areas... To securely fix the first row of plates, it is required to install special cleats, which are installed directly above the basement flashing. With their help, fiber cement products are firmly fixed to the vertical profiles of the frame with self-tapping screws.Above the first row, the next parallel of the clamps is mounted, which will hold the plates installed above.

Useful advice! Given the rather large weight of each individual slab - the thickness of the profile used for the frame, as well as the fasteners, it is necessary to choose with a large margin.

Installation of fiber cement panels around windows and doors

For the installation of such plates around windows or doors, an additional frame is created, completely framing the structures from all sides. For this, a metal profile is used. Installation is also carried out with self-tapping screws. Some slabs will need to be cut at a 45 degree angle for joining. In these places, after the installation of the entire structure, you will need to carefully go through the sealant.

For arranging openings, you can use a special decorative profile. It is attached to a window or door frame, and then the panels themselves are inserted into special grooves. The joints are usually hidden with additional staining. And protection against moisture is provided with a sealant.