During construction and repairs, a large amount of dirt, dust and debris is generated, the cleaning of which takes a lot of time and effort. A construction vacuum cleaner will help to solve this problem. The effectiveness of the device depends on how correctly its characteristics are selected. From this article, you can find out which construction vacuum cleaner to choose for solving problems of varying complexity and what indicators should be paid attention first of all.

The construction vacuum cleaner easily solves the problem of removing a large amount of dirt, dust and debris during construction and repair

Content [Hide]

- 1 Features of construction vacuum cleaners: industrial appliances

- 2 Industrial vacuum cleaner bags and filter systems

- 3 Filtration systems in bagless construction vacuum cleaners

- 4 Rating of the best bagless construction vacuum cleaners

- 5 Rating of construction vacuum cleaners of the budget segment

- 6 Quality rating of construction vacuum cleaners: prices for devices in the middle segment

- 7 Operation of construction vacuum cleaners: customer reviews

- 8 How to choose a construction vacuum cleaner for a wall chaser

- 9 DIY industrial vacuum cleaner manufacturing technology

Features of construction vacuum cleaners: industrial appliances

A construction waste vacuum cleaner and a regular household appliance have a similar structure and principle of operation, but each of them is designed to solve specific problems. This is their main difference, which was reflected not only in the design features, but also in the characteristics.

To choose a construction vacuum cleaner that will meet quality requirements, you need to take into account the main criteria:

- the conditions in which the device will be used (type of contamination);

- performance and power characteristics;

- the degree of rarefaction;

- dust collector capacity;

- body material and characteristics;

- availability of additional features and functions.

A household vacuum cleaner can handle light house dust and small debris. He will not be able to pick up small stones left after repairs or finishing work.With the help of such a device, it will not be possible to remove construction dust, because during suction, a significant part of the garbage will still return to the room along with the air flow.

Note! If building dust gets into the motor of a household vacuum cleaner, it can completely damage it.

Construction vacuum cleaners can be used to collect garbage both during the work itself and at the end of it.

As for the industrial concrete dust vacuum cleaner, this device is specially designed for the collection of construction waste. And only he is able to cope with such a volume of work. The construction analog differs from a conventional unit in a shock-resistant body and a high-power engine. The hoses for industrial vacuum cleaners have an increased diameter, which allows the device to remove rather large debris, for example, the remains of finishing materials.

Due to its improved characteristics, the industrial device can be used for other tasks as well:

- drainage of pool surfaces (bottom and walls);

- elimination of small dust particles left on the tool after use (for example, on a hammer drill);

- removing the remnants of old plaster.

Industrial vacuum cleaners for industrial premises can cope with cleaning large areas, because they are able to work without interruption for a long time, and also have a considerable amount of dust collector. Due to this, the weight of such structures has increased. Most of the models have a multi-stage filtration system, thanks to which the cleaning result is better.

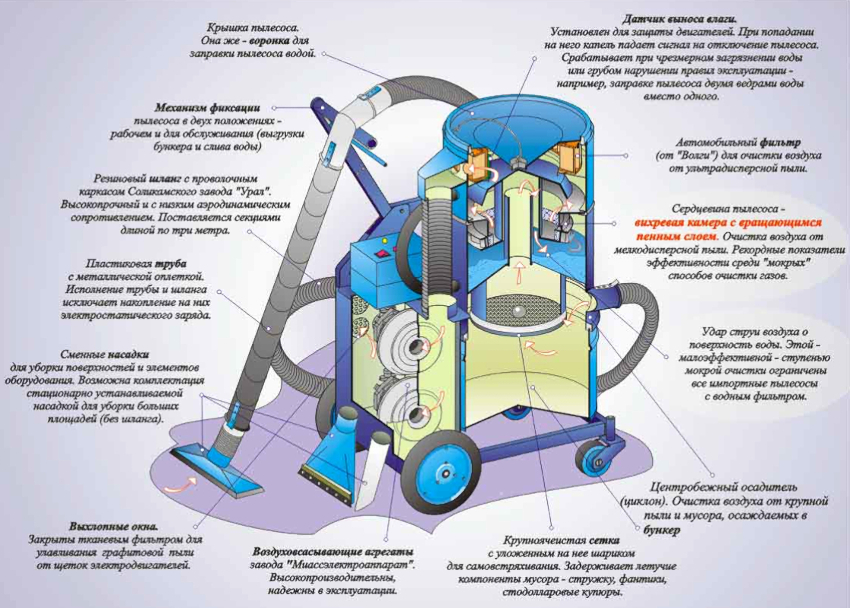

The internal structure of the vacuum cleaner and how it works

The principle of operation of an industrial and household vacuum cleaner is the same. An electric motor drives a fan inside the structure. As a result, a strong vacuum is created. Air flows together with debris and dust are directed through the hose to the area with reduced pressure.

Most of the debris that gets inside the vacuum cleaner is retained in the dust container. Smaller suspended particles in the air are captured by additional filters. When the streams pass through a multi-stage filtration system, the purified air is returned to the room through the outlet. Vacuum cleaners for construction dust can be used to collect dirt both during operation (preferably) and at the end of it.

If it is supposed to clean the working area, it is necessary to rigidly fix the vacuum cleaner hose in the immediate vicinity of the workpiece. This method reduces the amount of dust in the air during operation.

Important! Place the hose as close as possible without interfering with your work.

Many models of modern tools have a system designed to remove construction waste. For example, wall chasers are always used in conjunction with vacuum cleaners. This allows not only to increase the processing speed, but also to maintain accuracy. The drainage system has the form of a branch pipe that is connected through a hose to a construction vacuum cleaner for a wall chaser.

In this case, the amount of debris in the air and on the workpiece that is currently being processed is minimized. Of course, this method also has disadvantages, because a hose connected to a hand tool will interfere with work. However, this minor discomfort does not negate the benefits of this method.

Construction vacuum cleaners can be used after all the manipulations are completed. Cleaning in the premises and at the workplace in this case is carried out in the traditional way.

Industrial vacuum cleaner bags and filter systems

By the type of dust collector, industrial vacuum cleaners are bagless and bagless.Designs with bags can be completed with disposable paper products or reusable (fabric). In some models, the type of bag can be selected by the user at will, in other devices the choice is clearly spelled out by the manufacturer's recommendations.

The cleaning system includes not only a dust collector, but also filters that finely clean the air. They are disposable and reusable. Nylon products are designed to trap fine dust particles. Polyurethane filters are present in washing vacuum cleaners... There are also products made from other materials on sale, but all of them are of synthetic origin.

The cleaning system of an industrial vacuum cleaner includes not only a dust collector, but also a filter for fine air purification

The task of a filter for construction vacuum cleaners is to capture small dust particles that could not linger in a bag or other dust collector. The quality of cleaning depends on its effectiveness. In addition, the filter prevents premature engine wear.

Important! Filters, like dust collectors, must be cleaned regularly. If this is not done, the performance of the unit may decrease, and the load on the electric motor will also increase.

Advantages and Disadvantages of Fabric Bags for Industrial Vacuum Cleaners

Reusable cloth bags are the most common type of dust collector, as they are present even in household vacuum cleaners. After filling, the product must be emptied. To do this, the contents of the bag are carefully shaken out, and it is installed in its original place. The service life of fabric bags is quite long, so this version of the dust collector can be attributed to the budget category.

In older models of vacuum cleaners, bags made of satin were used. Modern devices are equipped with synthetic fabric dust collectors. Recently, manufacturers have begun to actively use interlining in the production of reusable bags for industrial vacuum cleaners for concrete dust.

The main advantage of fabric bags is their low cost, taking into account a considerable number of filling cycles. However, these products also have disadvantages that must be taken into account. The fabric is able to retain only large particles, while fine construction dust easily passes through the fibers. After that, it, together with the air stream, is thrown out through the outlet of the vacuum cleaner and spreads throughout the room.

The best industrial vacuum cleaners are equipped with fabric bags made of two-layer non-woven fabric. This material traps particles that are only a few microns in size.

Advantages and disadvantages of paper bags for construction vacuum cleaners

Disposable paper bags can be categorized as consumables. When the product is full, it is not cleaned, but simply thrown away with all its contents. On the one hand, this option is very convenient and saves time, on the other hand, it is accompanied by additional costs. Sooner or later, the cost of paper bags will exceed the price of an industrial vacuum cleaner.

In addition, the supply of disposable bags is quickly running out. This can happen at the most inopportune moment, and then you have to quit your job to go to the store for paper dust bags.

Note! Paper dust bags are not universal. It is not always possible to find bags for a specific model of a vacuum cleaner. Therefore, it is better to find out in advance in which stores you can purchase the corresponding type of product.

The use of disposable dust collectors also has positive aspects. These bags are characterized by excellent performance characteristics. Their effectiveness is significantly higher than that of fabric products.Paper dustbags can capture fine dust particles as small as 0.3 microns. This will keep the air in the room clean. Plus, you don't have to frequently change filters.

If paper bags are used in a construction vacuum cleaner for industrial dust, you need to be careful when cleaning large construction waste. Broken glass shards, metal shavings and sharp stones can damage the disposable dust container.

Filtration systems in bagless construction vacuum cleaners

The category of bagless vacuum cleaners includes two groups that have structural differences. Container units (cyclonic) and washing units (with aquafilters) are distinguished from the existing assortment. As with bags, these types of dust collectors have both advantages and disadvantages that you should definitely familiarize yourself with before purchasing a vacuum cleaner.

Features of Bagless Cyclonic Construction Vacuum Cleaners

Cyclonic construction vacuum cleaners have a built-in reservoir. Due to the centrifugal force, debris and dust are collected in this container. Such models of electrical appliances have significant drawbacks. First, they have a high level of noise impact. During the cleaning process, solid particles entering the container repeatedly collide with its walls. Therefore, a working vacuum cleaner makes a lot of noise.

Secondly, container-type vacuum cleaners have a limited scope. The fact is that the cyclone of a construction vacuum cleaner is suitable for collecting exceptionally large particles of debris. It handles fine dust worse. In addition, it is allowed to use such devices for cleaning moistened construction waste and water.

In some models of cyclone-type construction vacuum cleaners, the possibility of using bags is provided. The use of such dust collectors reduces the degree of contamination of the main filter during the operation of the device.

Helpful advice! Cyclonic vacuums are unable to pick up particles smaller than 5 microns. Bacteria, pollen, mites, etc. fall into this category. To get rid of such particles, it is advisable to use additional filtering attachments in the form of sponges.

Bagless construction vacuum cleaners with aquafilter

Devices equipped with an aquafilter suck in air and pass this flow through the water. The liquid retains coarse debris that settles on the bottom. Smaller particles are sent to the next tank, which is also filled with water. It is called a separator, and it is here that the remaining dust accumulates. This multi-stage cleaning system is highly efficient. However, consumers are reluctant to buy industrial cleaning vacuum cleaners because the price is very high.

Related article:

Rating of home vacuum cleaners from well-known manufacturers

The best vacuum cleaners from world brands. Popular models with different types of dust collectors. Vacuum cleaners for wet and dry cleaning.

In addition, vacuum cleaners with water filters are not designed to handle large amounts of debris. Water is the only consumable in such designs. On the one hand, this feature can be attributed to the advantages of aqua vacuum cleaners. However, it is far from always in the premises where construction or repair work is being carried out that there is access to large quantities of clean water. This is especially true for remote objects, for example, country or country houses, garages.

Note! In aqua vacuum cleaners, the electric drive is cooled by air. So that moisture does not come into contact with the power unit of the unit, some models provide different paths for the cooling and purified flows.When choosing a bagless industrial vacuum cleaner, you should give preference to just such safe and practical designs.

Vacuum cleaners with aquafilter not designed to handle large amounts of garbage

Rating of the best bagless construction vacuum cleaners

Bagless industrial vacuum cleaners for collecting dust have a long list of performance characteristics. The cost of these units depends on the technical parameters and functionality.

Considering the wide range of appliances in stores, many buyers experience difficulties in choosing and objectively evaluating vacuum cleaners. Therefore, the main criterion is consumer reviews, as well as the demand for certain models, which can be traced by the ratings of the best units.

Review of the construction vacuum cleaner Karcher WD 3 PREMIUM

With a total structure weight of 5.8 kg, the container of the Karcher WD 3 PREMIUM industrial vacuum cleaner has a large capacity. The volume of the reservoir for collecting dust and debris is 17 liters. This model is recognized by buyers as one of the most reliable. The design has a special cartridge filter. This component allows you to freely switch between wet and dry cleaning modes. In this case, you do not need to resort to changing the filter.

Thanks to the blowing function, the air intake speed is significantly increased. This advantage will come in handy when harvesting leaves at a summer cottage. The construction of the Karcher vacuum cleaner has a unique locking system that provides quick access to the built-in container. This model eliminates the need to constantly purchase dust bags. The 2 m hose extends the collection radius, making the vacuum cleaner easier to use.

The advantages of the model:

- positive user reviews on the network;

- aesthetic appearance;

- high quality;

- reinforced hull with increased safety margin;

- efficiency;

- modes of wet and dry cleaning.

The cost of this model of a construction vacuum cleaner is about 8000 rubles.

Characteristics of the construction vacuum cleaner Bosch GAS 20L SFC

In the category of the most efficient devices without a bag, the industrial vacuum cleaner Bosch GAS 20L SFC was recognized as the best. It greatly facilitates the work process, providing effective cleaning of dust, construction debris and dirt. The main advantage of this model is its durability. The unit is capable of working properly for many years, even with daily use.

Note! The suction tubes in Bosch vacuum cleaners are made of metal and coated with anodized coating. Thanks to this, they do not break or bend during the cleaning process.

Consumers have also awarded the Bosch GAS 20L SFC industrial vacuum cleaner the status of a very light unit. The structure weighs only 6 kg. This indicator is extremely rare among industrial devices. The presence of wheels makes it easier to transport the structure and makes it more mobile. Using the socket located on the body of the vacuum cleaner, you can connect an additional device.

Bosch vacuum cleaner GAS 20L SFC recognized as the best in the category of bagless construction devices

The display system allows you to check the fill level of the dust collection container. Filter cleaning can be carried out in a semi-automatic mode, which allows the owner to save time.

Vacuum cleaner advantages:

- stylish design;

- reliable and durable case;

- high durability of internal mechanisms;

- the ability to connect electrical appliances;

- efficiency;

- wet cleaning mode.

The only drawback of a vacuum cleaner is its high cost. The average cost of this model is 14,500 rubles.

Review of the highly efficient construction vacuum cleaner Makita VC2512L

In the category of devices with optimal capacity, the first line is occupied by the Makita VC2512L bagless industrial vacuum cleaner.This model performs well in the collection of construction waste, despite the average power rating of 1000 kW. The vacuum cleaner has a convenient system for cleaning the Push End Wedge filter. The length of the power cord is 5 m, which allows you to cover a large area during cleaning and increases the mobility of the structure.

To collect garbage, not only a container, but also a bag can be used. Both dustbins hold up to 25 liters. Thanks to the wheels, the vacuum cleaner can be easily moved from one place to another. This model can work in wet cleaning mode. The optimal technical characteristics of this vacuum cleaner will be useful to many owners during construction, finishing or renovation work. The unit is able to cope with any amount of work, and therefore it is even suitable for cleaning garbage in large rooms.

Advantages of the Makita industrial vacuum cleaner:

- long cable length (5 m);

- the container is made of stainless steel;

- wet cleaning mode;

- the package includes several additional attachments.

Like other models from this rating, this vacuum cleaner has a high cost (about 12,500 rubles). Many buyers will find this a significant drawback.

Interesting fact! Makita's company was founded in 1915, and it was located in a small garage. At that time, the main focus of the company was the sale and repair of lighting equipment, transformers and electric motors.

Features of the industrial vacuum cleaner Dastprom PP-220 / 20.3-1.5

The Russian-made Dastprom vacuum cleaner can operate in wet and dry cleaning modes, so it is perfect for cleaning industrial premises and collecting garbage at construction sites. With a power of only 1500 W, this model can draw in air at a speed of 132 l / s. This is made possible by the high vacuum, which reaches 300 mbar. Cleaning efficiency is not compromised even with such low energy consumption.

The manufacturer was able to achieve improved performance through the use of modern technology in the production of industrial dust vacuum cleaners. For example, the hose of the device has a low aerodynamic resistance. The filtration system is represented by two cyclones. In addition, a fine filter is installed in the structure.

The Dastprom universal vacuum cleaner is designed to work in difficult conditions, and you can use it around the clock. In order to protect the device from corrosion, the manufacturer covered its body with modern polymer material. Due to this, the service life of this model has significantly increased.

The dust collection container is made of high quality stainless steel. It can hold up to 20 liters. With considerable power and high performance, this model is compact in size. For easy transportation, the design has large wheels and a special handle.

Rating of construction vacuum cleaners of the budget segment

Most consumers purchase construction vacuum cleaners for home use. Such buyers rarely pay attention to models that are too powerful. Not only performance depends on this indicator, but also the price of a construction vacuum cleaner. In most cases, it doesn't make sense to overpay for power and features that won't be used. In addition, budget models will appeal to buyers looking for a compact and lightweight electrical appliance.

Helpful advice! When choosing a construction vacuum cleaner, it is better to give preference to models that have not a composite, but a telescopic pipe. It allows you to adjust the device to the user's height.

Overview of the characteristics of the industrial vacuum cleaner Soyuz PSS-7320

According to consumer reviews, the Soyuz PSS-7320 vacuum cleaner is an example of the optimal combination of price and quality among budget models. Due to its technical characteristics, this unit will be very useful during repairs. There is a socket on the body of the vacuum cleaner for connecting additional electrical appliances, which is an undoubted advantage and allows you to optimize the work process.

Paper bags with a volume of 20 liters are used as dust collectors in this model. They hold a large amount of construction waste. The vacuum cleaner can be used for both dry and wet cleaning. This unit is suitable for collecting waste in heavily contaminated areas. At the same time, the structure has a relatively low weight - 7.5 kg. The mobility of the device is provided by 4 wheels. They are durable and contribute to good stability.

Advantages of the Soyuz vacuum cleaner:

- the ability to connect an additional power tool;

- high efficiency;

- wet cleaning mode;

- acceptable cost (5400 rubles);

- in consumer reviews Soyuz PSS-7320 is shown from the good side;

- capacious dust collector.

Among the disadvantages of this model is only a small length of the power cord, which is 1.5 m.

Advantages and disadvantages of the Bort BSS-1010 vacuum cleaner

In the ranking of the best construction vacuum cleaners of the budget segment, Bort BSS-1010 takes the second position. This model is very compact and weighs only 3 kg, so it is not only convenient to use, but also does not need a lot of free storage space. The volume of the waste container is 10 liters. The vacuum cleaner has a wet cleaning function.

The electric motor of the vacuum cleaner develops a power of up to 1000 kW, which is an average figure. This model is not able to cope with large debris, but it effectively removes dust, dirt and other fine debris. The kit includes two nozzles. One of them is standard, and the second is used to process narrow slots. Thanks to these attachments, the vacuum cleaner can work effectively on any surface.

Note! For convenient storage of attachments, special niches are provided in the vacuum cleaner body.

Bort BSS-1010 advantages:

- lightweight construction;

- compact size;

- sufficient length of the power cord (2.5 m);

- wet cleaning mode;

- low noise level;

- affordable price (3000 rubles).

This model is not without its drawbacks. Among them are the small volume of the container for garbage collection and low capacity.

The third position in the rating of industrial vacuum cleaners: ZUBR PU-15-1200 M1

The cost of a small Russian-made vacuum cleaner ZUBR PU-15-1200 M1 is only 3700 rubles. This model got into the rating of the best units of the budget segment due to its favorable characteristics, as well as a long warranty (5 years).

Third place in rating of budget vacuum cleaners took the device BISON PU-15-1200 M1

This vacuum cleaner will help you remove debris:

- in premises after renovation;

- in a workshop;

- in the garage;

- in the basement.

The engine is capable of developing power up to 1200 W. The design of the vacuum cleaner is completely sealed for efficient suction. The body of the device is made of polyamide with a high margin of safety and impact resistance. This material does not lend itself to corrosion, is lightweight, so the vacuum cleaner itself is not heavy.

A HEPA filter is installed in the structure. It is designed for cleaning class L dirt, which include:

- lime;

- clay;

- a piece of chalk;

- cement, etc.

In their reviews, consumers note the high cleaning efficiency. In addition, users confirm that the unit works flawlessly during the 5-year warranty period, which is an indicator of its quality.

The vacuum cleaner has a HEPA filter, the use of which allows you to remove lime, clay, chalk, cement

Vacuum cleaner advantages:

- acceptable cost;

- compact size;

- durability;

- modes of wet (in small volumes) and dry cleaning;

- the possibility of using reusable fabric bags;

- Convenience due to the ergonomic handle, four stable wheels for transportation and low weight (4.5 kg).

In customer reviews, disadvantages are also indicated. First, the removable nozzles do not fit snugly against the hose. Secondly, when you first turn it on, an unpleasant smell of burnt plastic appears.

Note! This model is compatible with some types of electric construction tools.

Quality rating of construction vacuum cleaners: prices for devices in the middle segment

The more expensive the device, the more functions and possibilities it provides. Some of them are not necessary, but they greatly facilitate the operation.

Common functions:

- Power socket for connecting an additional tool.

- A regulator that allows you to adjust the suction power.

- Automatic or forced (manual) filter cleaning system.

- Splitters and adapters providing the ability to connect multiple work tools.

- Light indication system to indicate blockage or fill level of the dust container.

- Electric motor overload protection.

Industrial vacuum cleaner prices for concrete dust:

| Brand, model | Ranking place | Structure weight, kg | Power, W | Dust container volume, l | price, rub. |

| Redverg RD-VC7260 | 1 | 20 | 2400 | 60 | 18000 |

| Metabo AS 20L | 2 | 5 | 1200 | 20 | 9500 |

| Bosch GAS 20 L SFC | 3 | 6 | 1200 | 20 | 14500 |

| Karcher WD 5 PREMIUM | 4 | 9 | 1100 | 25 | 10000 |

| Thomas SUPER 30S AQUAFILTE | 5 | 7,5 | 1400 | 30 | 15500 |

| Hitachi WDE3600 | 6 | 10,6 | 1200 | 30 | 17700 |

| Karcher MV 6 Premium | 7 | 9,4 | 1300 | 30 | 17900 |

| Makita VC 2512L | 8 | 8,5 | 1000 | 25 | 11200 |

| Makita VC 2012L | 9 | 8,5 | 1000 | 20 | 13000 |

| Bosch GAS 15 PS 0.601.9E5.100 | 10 | 6 | 1100 | 15 | 11500 |

Important! When choosing a construction vacuum cleaner with a power outlet, it is imperative to take into account the power of the devices that will be connected to it during operation.

Operation of construction vacuum cleaners: customer reviews

Many buyers regard reviews as one of the most important indicators of quality. This is due to the fact that the comments of consumers, who have already managed to check the capabilities of a particular model during operation, more broadly describe the strengths and weaknesses of vacuum cleaners:

“I purchased the Metabo ASR 50 L SC 602034000 construction vacuum cleaner as an addition to the old Bosch unit, which is still working properly, but I would not like to drive it completely. The device functions perfectly, tested it on a concrete grinder and on a wall chaser. The filters are easy to clean. Another significant plus is the presence of a pollution indicator.

I would like the manufacturer to equip the wheels with brakes. Who decides to buy this unit, I advise you to immediately purchase brushes for it. The ones that come with the standard kit are not enough. Plus, they're not very comfortable. "

Igor Radushny, St. Petersburg

“I have been using a Nilfisk industrial vacuum cleaner for a couple of months now. I was looking for a device for cleaning apartments after renovation and decided to stop at the ATTIX 33-2L IC MOBILE 107412104 model. During this time, the vacuum cleaner showed itself normally, excellent power, easy to use. There is only one drawback - there is no storage space for nozzles and pipes. Let's see how he will behave over time. "

Dmitry Ivashin, Moscow

How to choose a construction vacuum cleaner for a wall chaser

Vacuum cleaners used in conjunction with construction tools not only facilitate the work process, but also protect the health of builders who, by virtue of their profession, constantly have to deal with dust and debris. Each master selects the unit for himself.

Vacuum cleaners used in conjunction with construction tools not only make the process easier, but also protect the health of workers

However, there is a general list of criteria to consider when buying a channeler vacuum cleaner:

- compatibility of the diameters of the vacuum cleaner and the chasing cutter in the connection area;

- devices must be combined with each other in terms of power level;

- suction speed (if this indicator is small, the vacuum cleaner will not be able to carry out high-quality cleaning);

- the volume of the garbage tank;

- strength characteristics.

In quality vacuum cleaners, the housing is made of durable materials that can withstand heavy impacts. The filtration system is also of great importance.

Note! The more levels of cleaning, the better the filtration system works.

In the rating of the best construction vacuum cleaners, to which you can connect a wall chaser, the first places are occupied by devices from German manufacturers

In the rating of high-quality construction vacuum cleaners, to which the wall chaser is connected, the first place, according to buyers, is occupied by the products of Makita. The devices are affordable and easy to use. The second position is occupied by Karcher vacuum cleaners, which do an excellent job of cleaning dust that occurs when processing natural stone, brick, expanded clay, cinder blocks and concrete. The products of the German brand Bosch are worthy of attention. These vacuum cleaners, unlike the previous versions, suck up dust more slowly, but they are excellent at removing static electricity.

DIY industrial vacuum cleaner manufacturing technology

There are many ways to create an industrial vacuum cleaner at home. The most practical option involves making a structure based on a cyclone filter and a household vacuum cleaner.

In addition, for work you will need:

- a bucket with a lid of 20 liters;

- PP corners (45 ° and 90 °);

- tube 1 m long and 45 mm in diameter.

First you need to make a hole in the lid of the bucket, where you should install a 90 ° corner. The junction between these two parts must be sealed. For this, you can use a construction gun and glue. A second hole is formed on the side of it. Install a 45 ° angle here. In this zone, the joints are sealed in the manner described earlier.

Then, a corrugated pipe should be attached to the corner. It is desirable that it fit as tightly as possible, then you do not have to do additional sealing. A great option would be a pipe from a kitchen sink siphon. This product fits seamlessly onto a 45 mm tube and creates a tight connection with the vacuum opening.

To extend the life of the cyclone, which can be installed above the bucket (saves space in the waste container) or in it (under the lid), you should use a nylon cloth.

The technology for making a homemade debris vacuum cleaner is quite simple. Nevertheless, hundreds of budget models can be found on sale. They will do a good job of cleaning home workshops and premises after renovation. However, to use the vacuum cleaner for professional purposes and on an industrial scale, it is desirable to purchase more expensive and powerful modifications.