Various sheds from a metal profile: their photos can often be found when looking for options for arranging various outbuildings, it is not so difficult to make it yourself. To do this, you need to have basic skills in working with a welding machine and grinding technology.

Content [Hide]

Metal profile canopies: photos of various options

Very often there is a need to build near your house canopy for any purpose. It could be canopy over the terrace for relaxation or alcove, garage or just a warehouse for various home and garden tools. The structure can be detached or adjacent to another building or house. Today, canopies are most often made from metal profiles. Photos of various options and drawings can be found in the public domain. In addition, the cost of such a structure is quite within the power of most owners.

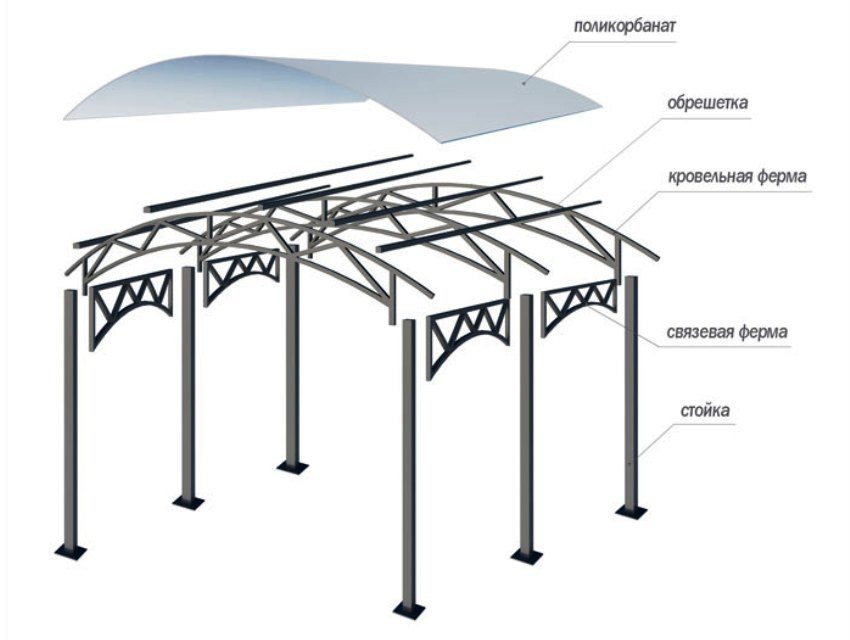

For the installation of the simplest canopy you will need to purchase a profile pipe of various sizes and a profiled sheet for the roof and, if necessary, for the walls. Alternatively, the roof can be made of polycarbonate. The design of the canopy depends on its purpose and size. This also affects the parameters of the profile pipe for the racks. Canopy can be open and closed. In addition to the roof, the closed shed also has walls.

A canopy over the porch with a sloping roof made of corrugated board

Roof designs vary. The simplest and most common is pitched roof... Often they do it gable... IN gazebos and terraces for recreation, the roof is made in the form of a pyramid, and sometimes even in the Chinese style with upward curved edges. With the advent of flexible roofing materials, arched roofs covered with polycarbonate have become popular. Curved trusses for them can only be made on a special machine.

In order to independently make a canopy from a metal profile, the photo of which will take its rightful place among the best samples, you must follow certain rules, which you must familiarize yourself with before starting construction.

Helpful advice! If you decide to make a canopy from a metal profile yourself, but you are doing it for the first time, you should not choose complex structures. Better to stay on simple rectilinear forms. This will allow you to build a pretty decent canopy without proper experience.

How to build the simplest metal profile canopy

In order to understand the technology of building a canopy from a metal profile, take, for example, the construction of a garage with dimensions of 6x3 m with a simple gable roof and walls.Before starting work, it is necessary to make the necessary calculations, since the thickness of the metal supports and crossbars depends on the amount of precipitation in a given area.

For the middle lane, when constructing a structure of this size, 8 pipes with a diameter of 80 to 100 mm will be required. If they have a square section, then 100x100 mm will be enough. For the rest of the structural elements, square pipes 50x50 mm and rectangular pipes 25x40 mm, as well as fittings, are suitable.

A certain amount of additional materials and a simple tool will be needed to carry out work on the construction of a canopy from a metal profile. Photos of finished objects tell us nothing about this, so we list everything that will be needed:

- household apparatus for electric arc welding;

- ladder;

- grinding machine (grinder);

- hacksaw, tape measure, level, hammer, pliers, shovel;

- cordless screwdriver, drill, drill;

- shaped pipes, corners, fittings;

- cement, sand, crushed stone;

- roofing screws, bolts;

- mittens.

Helpful advice! If you plan to use corrugated board with a polymer coating for the roof, you should not cut it with a grinder. This will degrade the polymer by high heat, leading to premature corrosion.

Site preparation and earthworks

Before starting construction canopy, you need to choose a suitable place. It is desirable that it be the highest and with the minimum slope. If you still have a choice, then you need to look for the place where the clay is closest to the surface. When you have to build in a low area, you should take care of the drainage and drainage.

Related article:

A canopy attached to the house. Photos of different types and configurations. Cantilever canopies and support structures. Installation of polycarbonate canopy, frame installation, pile pouring, roof sheathing.

If you plan to make a garage with a hard concrete floor, then from the entire area you need to remove the soil to the very clay and make a sand-crushed stone pillow, which must be carefully tamped. After that, a cement screed is made. The holes for the supports are drilled with a drill to a depth of 50 cm. The bottom of the holes is covered with sand and gravel to create a dense cushion.

Construction of the canopy frame

Each hole is filled in half with a solution, after which a support is placed in it. Using a plumb line, it is installed in a strictly vertical position and fixed. After that, the hole is filled with a solution to the top.

Helpful advice! In order for the supports to stand more reliably in the ground, it is necessary to weld metal squares or circles to their lower part, so that they fit into the hole. This will allow you to better fix them, and it will also be more convenient to fix them until the solution has frozen.

When all the pits are filled with mortar, it is necessary to wait for the reliable fixation of the canopy supports from the metal profile. A photo of this stage of construction shows how even the supports are exposed. As a general rule, you need to wait at least a day, but preferably more.

After the solution hardens, you can level all the supports in height and weld squares with a side of 150 mm to their upper part. They are needed for the subsequent installation of roof trusses on them. Instead of squares, you can also use pieces of the channel. Then strapping is done using shaped pipes... This can be done at the top and bottom. Sometimes, for rigidity, a diagonal strapping is made between the supports. Spacers are welded to the top of one support and the bottom of the other. This is repeated at all intervals.

For the installation of a gable roof, the construction of triangular trusses is required. They can be welded from a 50x50 mm square tube. A piece of the same pipe is welded between the ridge and the underside of the triangle. The length of the roof slopes depends on the slope angles.All these parameters are calculated according to the Pythagorean theorem. For rigidity, reinforcement is welded in each truss. Its thickness can be from 8 to 10 mm. It must be welded crosswise inside the farm.

Each triangular truss is installed on adjacent supports and welded to them. Then from a pipe 25x40 mm. the lathing is made in increments of 40 - 50 cm. Roofing sheeting is screwed onto this lathing using self-tapping screws with rubber gaskets. Sheets of the required length must be prepared in advance.

The walls of the canopy are made of wall corrugated board, which is attached to the upper and lower straps with self-tapping screws. At the last stage, a double-leaf gate frame is cooked from a profile pipe, which is attached with canopies to the posts. Goal sheathed with the same corrugated board.

Such a garage, made as a closed canopy made of a metal profile, the photo of which can be appreciated at its true worth, cannot be called warm, but it may well protect the car from snow, rain or hail. Since it reliably protects from the wind, the temperature in it in winter will be 2 - 3 degrees higher than in the open air. In order for the design to be smooth and neat, all measurements must be made accurately, and when fastened in place, it is necessary to use the building level.