This article outlines a technology that describes how to lay paving slabs at the stage of installing curbs, various options for their installation are considered. You will find out what types of borders exist, familiarize yourself with the rules for choosing high-quality materials, consider the technical and operational characteristics of each of them. Check out the prices for the purchase of materials and turnkey paving services.

Content [Hide]

Decorating paths with curbs and paving slabs: how to properly lay the coating

The arrangement of the personal plot is not complete without the formation of paths. These elements perform several useful functions at once.

In suburban areas, tiled flooring is used for:

- preservation of the grassy lawn coverage (paths allow you to move around the site without trampling the grass);

- visual division of the area of the site into zones (with the help of them you can arrange a recreation area, a blind area around the house, the space around flower beds, pools, greenhouses, gazebos and awnings, etc.);

- decorating the site and maintaining the overall design of the backyard and the house itself.

Note! The cost of laying paving slabs includes not only the purchase of material and the paving itself, but also the installation of curbs, if they are supposed to be installed. In order to save money, you can do this work yourself, the main thing is to adhere to the technology.

Classification of curbs for paving slabs: how to install the right option

Curbs have a beautiful appearance, they are durable and practical, therefore they are often installed before laying paving slabs on sand and other types of surfaces. These elements are able to fit into any architectural solution of your yard, to give a complete look to the entire site.

Curbs act as protection of lawns and tiled surfaces from erosion.They are able to increase the operating life of the tracks.

The general classification of curbs by type of material of manufacture includes the following varieties:

- metal;

- plastic;

- concrete;

- brick;

- wooden (rarely used);

- from natural stone.

Laying curbs for paving slabs is also used to indicate the difference in height between the level of the lawn and the surface of the path. To make the right choice of the border, you should study in detail the technical characteristics of the most common types of material.

The existing varieties of concrete curbs are also classified according to manufacturing technology, among them are:

- concrete curbs;

- vibrated curbs;

- sidewalk curbs.

Each of them is able to offer certain advantages and technical characteristics that will be useful to owners of suburban areas when laying paving slabs on a dry mix. The technology involves paving on a sandy or concrete base.

Features of installing curbs for concrete paving slabs

Factory-made concrete curb is in high demand among the owners of suburban areas. Most often it is used when laying paving slabs on a concrete base, since this type of product has a long service life and is characterized by a simple installation system.

Helpful advice! Prefabricated concrete curbs come in a wide range of colors. Take advantage of this when designing garden paths and alleys. With the help of a colored curb, you can create a unique design for pedestrian areas.

Technical characteristics of concrete curbs:

- the level of water absorption is 6%;

- high compressive strength - 22.5 MPa;

- the material is quite easy to process (if necessary, cutting the concrete curb can be cut);

- high level of frost resistance.

Thanks to all these characteristics, the installation of curbs for paving slabs with your own hands will be of high quality and reliable. A wide range of products allows you to go beyond strict design boundaries.

If you decide to use the services of paving in a specialized company, the size and type of curbs will affect how much it costs to install paving slabs. Especially if the purchase of materials is carried out by the company itself.

Concrete curb for paving slabs: product price

To save on the cost of laying paving slabs ordered from a specialized company, you can purchase all consumables yourself.

Average prices for the purchase of concrete curbs:

| Item type(appointment) | Colour | Dimensional parameters, (width / length / height), cm | Price,RUB / m² |

| Road curb | White | 15x100x30 | 345 |

| Gray | 15x100x30 | 274 | |

| Color Mix | 8x100x20 | 163 | |

| Sidewalk curb | White | 8x100x20 | 163 |

| Wine | 8x100x20 | 163 | |

| Gray | 8x100x20 | 140 | |

| Drainage tray | Brown | 20x50x6 | 364 |

| Gray (asphalt) | 50x100x180 / 230 | 876 | |

| Gray | 20x50x6 | 274 |

Helpful advice! Include the road curbs indicated in the table in the technology for laying paving slabs under the car. These products will keep your area safe by limiting vehicle movement.

Vibrated curbs on a suburban area

Vibro-cast products are distinguished by their increased wear resistance. In the process of manufacturing such borders, coloring pigments and plasticizers are added to the raw materials.

Manufacturers produce products of various shapes. In addition to standard rectangles, buyers can purchase borders of the following shapes:

- step;

- arc;

- wave, etc.

Often, clinker bricks are used as sidewalk curbs. This type of material has a high strength indicator, long service life, while it is completely environmentally friendly.

On the other hand, if you are thinking about how to properly lay paving slabs with your own hands, the use of clinker bricks in your work should be avoided. The fact is that the blocks are large, which is why large gaps arise between the workpieces during the installation process, through which grass and other plants subsequently grow. Their presence adversely affects the condition of the coating.

If you want to buy curbs for paving slabs, the price of vibrated products depends on the size and color.

Average prices for vibrated curbs:

| Dimensional parameters of the product, (width / length / height), cm | Colors | Price, rub / piece |

| 21x50x7 | Gray | 59 |

| Red | 79 | |

| Yellow | 99 | |

| Brown | 99 | |

| 20x50x3 | Gray | 39 |

| Red | 69 | |

| Yellow | 79 | |

| Brown | 79 |

Metal, brick and flexible curbs for paving slabs

Plastic curbs for paving slabs are versatile products. They are in harmony with various style directions in the design of personal plots, and thanks to a large selection of colors, they make the design of the paths unique.

Helpful advice! Plastic curbs have a flexible structure. Use this material property to design curved paths with smooth lines.

In addition to durability and resistance to corrosion, plastic products are also characterized by an affordable cost. They are best suited for DIY sidewalk mounting.

Various raw materials are used for metal-based curbs:

- stainless steel;

- aluminum;

- copper.

Metal curbs are used to equip straight paths with straight turns. They are used not only for organizing paving slabs, but also combined with paths made of rubble.

Brick curbs are no less common than other types of products for similar purposes. There are several technologies that describe how to lay paving slabs in a brick-framed yard. In one case, the laying of the blanks can be carried out in a horizontal position, in the other, the brick is placed at a diagonal slope. The result is a beautiful jagged track frame.

This type of material goes well with the coating of paving stones, especially if the design of your local area is made in the English style. It is worth noting that it is not recommended to install bricks as a curb in areas where there are frequent and heavy rains, and a high level of precipitation falls. Under the influence of a large amount of moisture, this material collapses very quickly.

How to lay paving slabs using a curb: the right choice of materials

The area of application of sidewalk curbs extends to pedestrian zones, sidewalks along the carriageway, as well as paths in the private sector. The owners of suburban areas use this type of building material as a budget solution for the decoration of the yard and other areas.

Helpful advice! Sidewalk curbs are usually combined with tiles or paving stones. In this regard, many manufacturers began to add coloring pigments to their raw materials. You can successfully beat the floor using contrasting colors.

If we compare the sidewalk version of products with other types of curbs, a number of advantages can be distinguished:

- high level of wear resistance;

- strength and reliability;

- resistance to sudden temperature changes;

- almost perfect surface cleanliness;

- resistance to moisture;

- invulnerability to the influence of chemicals (even the use of icy reagents is allowed);

- wide range of colors;

- there is no need to carry out additional external finishing.

Within the framework of the classification, one-sided and two-sided sidewalk curbs are distinguished. The first of them are used for paved areas, as well as sidewalks made in longline technique. The latter are good if the paths are on the same level with the lawn, the curb in this case acts as a separator.

The size of the curbs for paving slabs

The modern assortment of the construction market offers many variations of borders in terms of size. Thanks to this, each consumer can find products that meet his requirements.

Classification of curbs by size:

- curbs - the size range includes products with the following parameters: 8x21x50, 5x20x100, 4.5x21x50 cm;

- park blocks - the overall dimensions of the product are 7x21.1x50 cm;

- curb for road surfaces - correspond to the size of 20x60x300 cm.

Factory-made sidewalk curbs usually correspond to standard sizes - 8x20 or 5x20 cm. Rectangular products have a wider range of sizes, including small borders with parameters 0.6x2x5 cm, as well as large ones - 8x20x100 cm.

Helpful advice! On the net you can find a video on how to properly lay paving slabs in combination with various types of curbs. Use such visual materials to avoid mistakes in the paving process.

If it is planned to organize pedestrian paths, it is recommended to use curbs, the height of which is 30 cm, and the width is no more than 20 cm. The alleys are fenced with lighter versions of products with parameters 8x20 cm.

Quality of curbs for paving slabs: how to install the material correctly

Recommendations on how to lay the paving slabs in the yard yourself are limited not only by the technology itself, but also by advice on the choice of materials. The quality of the borders, like the tiles themselves, has a direct impact on the final result, so the material selection process is extremely important.

The procurement process should be guided by several criteria:

- Technical characteristics - this includes the type of border, its structure and dimensional parameters, as well as shape features.

- Indicators reflecting the level of strength of products.

- Service life of curbs.

- Prices for laying paving slabs without a border and with a border (if the use of specialist services is expected).

- Resistance to temperature extremes, as well as environmental factors.

- The quality of painting the workpieces (how evenly the surface of the border is painted).

- Features of the object for laying tiles (type of track or platform, area, shape and slope of the surface).

Before purchasing material, decide on what is better to lay paving slabs and what kind of base you can provide them on your site. The type of material that will need to be purchased directly depends on this. The most common base for paving is soil, with a pre-formed cushion of sand, gravel or concrete.

Note! Many people wonder whether it is possible to lay paving slabs on the asphalt, having at their disposal the old asphalt surface in the yard. In fact, it is possible, but for this you will have to carry out a number of preparatory work to ensure the quality of the coating.

Laying of paving slabs: prices for professional services

After purchasing the material, it is worth deciding whether you will do all the paving work yourself or hire specialists for this. In each case, you get certain benefits.

On the one hand, the independent execution of work guarantees significant savings in money. On the other hand, professional service is a guarantee of high-quality and reliable results, of course, if you find really skillful and qualified specialists.

How much does it cost to lay paving slabs (average prices):

| Type of work | Price, rub./m² |

| Formation of the base from rubble | 100 |

| Installation of curbs (running meters) | 180 |

| Paving slabs | 400 |

| Dismantling the old coating | 240 |

| Unloading and loading of construction waste | 150 |

| Material handling (10 km) | 1000 |

How to lay paving slabs with your own hands: work on installing curbs

Everyone can handle the installation of plastic curbs. This does not require serious preparatory work. There is no need to dig a special trench, form a concrete base or lay it before laying a curb for paving slabs made of plastic geotextile.

First you need to outline the contour of the path and the height of the curb itself. Most manufacturers produce products that have holes on the outside for attaching anchors or marking pegs. Thanks to this fastening, the fixing of the curb on the ground is strong and reliable. For work, you will only need a hammer to hammer in the metal pegs.

Note! The edges of the plastic are very easy to dock, and the products themselves bend well. You can make a path or a platform of the most bizarre shape, without fear that the ends of the curbs will not converge, and the framing will turn out to be sloppy.

How to lay curbs for concrete and natural stone paving slabs

The use of concrete curbs assumes that the pavement will be subjected to significant stress. For this reason, the strength of the fixation comes first when organizing the track.

At the initial stage of the work, a trench should be dug, placing it along the contour of the object. The depth depends on how high the curb is and how much it should rise above the surface itself in the end.

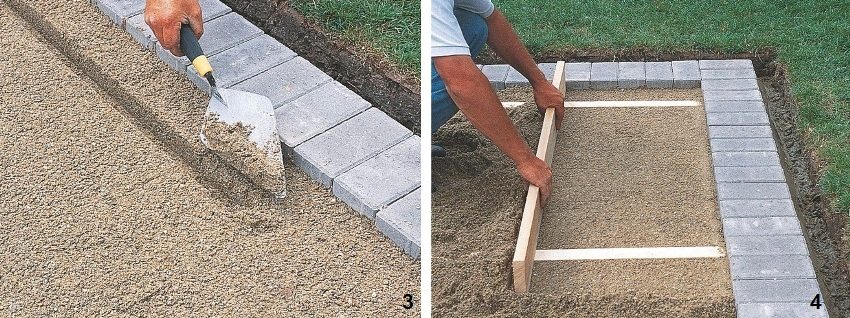

After that, the trench should be filled with concrete. The proportions for preparing a mixture of cement and sand are 1: 3, respectively. The fill is leveled and concrete curbs are installed. This must be done as carefully as possible, placing stones as close to the edge of the path as possible. Do not make the mixture too liquid, in this composition the elements will blur and fixation will become impossible.

When several curbs have already been installed, additional fastening of the first and then all subsequent stones should be performed in the order of installation sequence using an additional layer of cement in several places. The ideal projection height is 50 mm.

After the mortar has set and hardens, the trench is sprinkled on the outside with sand or earth. This will allow you to keep the structure in its original form for a long time and increase its service life.

Related article:

Paving slabs for paths in the country. Prices, types and styles. A variety of paths in the country, paved with paving slabs. Correct selection and laying of paving slabs. Recommendations and video editing.

If you decide to make natural stone curbs, you don't need to dig a trench. It is enough only to remove a thin layer of soil in order to make a geotextile flooring. Then, large stones are placed on this bedding as closely as possible to each other. Finally, all the remaining voids are filled with dry cement.

Note! If large gaps have formed between the stones, they must be filled with small stones before filling them with cement.

Despite the fact that the work seems very simple, you should take responsibility for its implementation, since the durability of the tile coating depends on the quality of the base.

How to lay paving slabs: videos and recommendations

After the curbs are installed and securely fixed, we lay down the paving slabs with our own hands, the video material with the technology will help you figure it out.

Key recommendations for laying paving slabs:

- for reliability, fix the first row of tiles with cement mortar along the edge part. Thanks to this, the coating will not move;

Installation of curbs, preparation of the base for paving and laying tiles on cement mortar

- start paving from the curb;

- when sinking the workpieces into the base (if laid on sand), observe the same depth, be guided by the level;

- the maximum clearance is 5 mm. Don't do more. It is not recommended to lay tiles without gaps;

- use a grinder to cut the material;

- use only clean sand to fill the joints. Leave it on for a few days for perfect filling;

- the optimal proportions for preparing a mixture of sand and cement are 1:10. In areas where drains are placed and in other wet places, it is better to take a ratio of 1: 3 for filling joints;

- do not load the track until all joints have been processed.

Remember, the cobbled walkways and areas need to be maintained. Clean the surface from time to time. Moreover, colored tiles require more attention in this regard than gray ones. In winter, use wood and plastic tools to remove ice and snow; metal tools can damage the coating. Do not paint, this procedure will reduce the quality of the coating and its durability.