The text discusses in detail such a type of material as cork flooring. From the article, you can find out what this type of finish is, what properties and characteristics it has, as well as evaluate the advisability of using natural coating in the interior by examining its advantages and disadvantages, consumer reviews, average prices and other factors.

Content [Hide]

- 1 Characteristics of cork floors, pros and cons

- 2 Pros and cons of cork floors, photos, prices for various types of coverage

- 2.1 Features of cork floor tiles

- 2.2 Cost of floating cork floors: price per meter of finishing

- 2.3 Features and specifications of adhesive cork floors

- 2.4 Average cost of glued cork floors: price per m2

- 2.5 What is the purpose of placing a technical plug on the floor

- 2.6 Which is better to buy a cork floor: adhesive or floating

- 3 The choice of cork floors: owner reviews, pros and cons

- 4 What cork floors look like in the interior: photo

Characteristics of cork floors, pros and cons

Cork flooring is made from porous oak bark. The extraction of this material does not have a negative impact on nature. The place where the bark was cut continues to grow and renew, which allows you to perform this procedure every 9 years without threatening the condition of the tree. Raw materials from 25-year-old oak trees are used for the production of flooring. Younger trees are not suitable for this. The most valuable is the bark cut from 150-year-old oak trees.

When buying a coating, you should carefully look at the entire batch for chips, irregularities and other manufacturing defects.

A mixture of pressed bark is used as a base for the coating. As a result of special processing inside the furnace, the material is saturated with air. In this case, natural juice contained in micropores is used. He is called suberin. At the next stage, the material is given strength. For the so-called reinforcement, resins and wood dust are used, which are added in several layers.

The top layer is made of cork or other materials such as veneer or PVC. The scope of application of the floors, as well as their service life, depends on the properties and characteristics of the top coating.

To protect the coating from wear, as well as to give it a certain design, manufacturers use veneer in combination with cladding with other materials:

- veneer - the layer thickness is only 0.5 mm.The coating is applied over the base on the adhesive composition;

- veneer varnished for cork flooring - the varnish increases the life of the finish, which is ideal for living rooms, including bedrooms;

- veneer covered with a protective vinyl film - it prevents scratches, and also prevents moisture from entering the material. Thanks to this, the manufacturer's warranty extends for 10 years;

- veneer made of fine wood and covered with vinyl film - the material is a veneer of natural origin, made from expensive wood species. For protection, it is covered with a layer of vinyl.

Note! Thanks to modern technology, consumers can buy cork flooring in any design. The method of photo printing allows you to apply a realistic imitation of grass, wood, sand, stone, etc. to the surface of the material.

Cork flooring: material advantages

Cork as a floor covering has many benefits. This finishing material is lightweight in comparison with other types of coatings. The cork is characterized by soundproofing. The material does not allow noise to pass through, so it is suitable even for recording studios. At the same time, the finishing has a low level of thermal conductivity, due to which the heat of the room does not go into the floor, but is stored inside.

The surface of the cork is elastic and soft. Orthopedic specialists recommend using this type of decoration for people with diseases of the musculoskeletal system, as well as as a coating in children's rooms. The cork is safe and environmentally friendly. Its surface does not slip, does not absorb liquids and does not emit harmful substances. In addition, the material has antistatic properties. The cork does not need any difficult maintenance and perfectly repels dust.

The coating is resistant to liquids and chemicals. The exception is caustic solutions of alkaline origin. The plug does not impede natural air circulation. Thanks to this, the material does not contribute to the growth of bacteria and the aggravation of allergic reactions among the residents of the house. The cork is not subject to decay. She is not afraid of moisture. If the floors in the house get wet as a result of flooding, the coating will not deteriorate under the influence of the liquid, but provided that the surface has a protective treatment.

The cork is not afraid of temperature changes and is not subject to fading in the sun. Unlike laminate flooring, this material can be laid on loggias and open balconies. This type of coating is very strong and durable. Due to its porous structure, the material reduces the level of friction, therefore, the aggressiveness of external factors of influence decreases.

Cons of cork floors

Like any type of flooring, cork floors have advantages and disadvantages. Due to its softness, the coating squeezes over time under the weight of the furniture. Specially for bathrooms, manufacturers produce slabs with a thickness of 1-1.2 cm. The size of such products is 14.8x14.8 cm. If the coating in the bathroom is thinner, there is a possibility that the bathtub will pierce it through.

Do not walk indoors in shoes with rubber soles or high heels, otherwise marks will remain on the surface of the coating. Also, avoid placing latex or rubber rugs on the floor. The trace from these products after a long stay is practically not removed.

Helpful advice! The pits left by the chair legs and light furniture will align themselves.For heavy furnishings, it is advisable to buy soft felt pads that will reduce pressure.

The thickness of the covering under the bathroom or heavy furniture must be greater than the thickness of the main covering

A significant disadvantage is the price of a cork floor. Moreover, the adhesive type of coating will cost significantly more than a cork laminate. On the other hand, due to the simplified installation of the key plates, the costs of purchasing the material are partially offset. As a result, the total cost of the covering will be lower than that of natural parquet.

Another disadvantage of cork is flammability. The material itself is not flammable. The flammable component of floors is its protective coatings, for example, paint, varnish, glue. The natural coating has a low level of resistance to moisture. This disadvantage can be eliminated with varnish, sealant or wax impregnation.

Some coating options (for example, adhesive-type floors) have a complex installation system. Only specialists can provide high-quality performance of such works. In addition, it is impossible to install the underfloor heating system under a cork floor. The material has a high degree of thermal insulation, so heat fluxes cannot enter the room.

Pros and cons of cork floors, photos, prices for various types of coverage

Manufacturers produce three types of cork, which are used as floor coverings:

- solid veneer - the material consists of solid pieces of tree bark (this type of finish has a high price and is used to decorate ceiling and wall surfaces, as well as niches);

- glomerate - the material looks like sheets, consisting of crushed bark, joined together by gluing (this type of finish is practical and affordable);

- combined cork - consists of agglomerate and veneer, they are glued together under high pressure.

For the production of combined cork, veneer is used, which is not suitable for the manufacture of plates. As a result, the finish acquires a decorative appearance and a beautiful texture. The combination cork works well with other materials.

There are the following types of coatings:

- Floating or castle floor.

- Adhesive floor.

- Technical plug.

They have different properties and are characterized by a specific field of application.

Features of cork floor tiles

The floating floor consists of slabs interconnected by means of locking joints. The thickness of these panels varies between 10.5-12 mm. The size of the tiles is 18.5x90 cm. The finish is laid in the same way as a regular laminate.

For the manufacture of the base of these plates, crushed chips are used. Wood or cork is used as a finishing coat, which is covered with a layer of paint and a print. It is advisable to use this type of finish in well-heated rooms where there are no temperature extremes. Abrupt changes can negatively affect the condition of the lock connections.

Important! When buying plates, be sure to pay attention to the quality of the locking joints. The integrity of the coating and its durability depend on them.

It is not recommended to use floating cork floors in high traffic areas such as walkways or kitchens. The coating installation system is quite simple. If one of the fragments is damaged during operation, a whole row will have to be disassembled. The section from the wall to the place where the defective element is located is subject to dismantling.

There is moisture resistant Cork board on the floor (laminate). The base in this material is a slab made of quartz and PVC.This type of coating has a higher price, while the choice of colors is limited.

Related article:

Floors in the apartment: what to make and how to choose

Parameters influencing the selection. Properties of various materials. Features of the floor in different rooms. Additional floor modifications.

Cost of floating cork floors: price per meter of finishing

The leading manufacturers and suppliers of cork coverings are Spain and Portugal, where porous oaks are widespread. Products from Asian countries are in lower demand, as the climatic conditions of this region do not allow the production of high quality wood.

Average cost of 1 m² of Wicanders floating cork floors:

| Collection name | Price, RUB / m² |

| Originals | 1650 |

| Identity | 2150 |

| Personality | 2150 |

| Cork veneers | 2220 |

| Character | 2280 |

| Linn | 2390 |

| Cork plank | 2450 |

| Homecork | 2490 |

| Artcomfort Wood | 2500 |

| Artcomfort Stone | 2550 |

Features and specifications of adhesive cork floors

The adhesive floor consists of cork panels with an additional protective coating. The thickness of these elements is 4-6 mm. The material has a two-layer structure. At the bottom there is pressed cork chips, and the finishing layer on the panels is veneer. The elements can be either rectangular (60x30 and 45x15 cm) or square (40x40 and 30x30 cm). This type of coating is suitable for rooms with high levels of humidity, such as bathrooms and kitchens.

Before carrying out the installation, you need to carefully prepare the surface. The base for the installation of the coating must be perfectly flat. Glue is used to fix the panels. In order for the result of laying the coating to be of high quality and durable, all elements must be carefully adjusted. Backlash is not allowed.

With this material you can create decorative ornaments and patterns on the floor. When the installation is completed, the cork is coated with a polyurethane-based varnish in several layers. It is imperative to process the gaps between the modular elements.

Helpful advice! If one of the fragments is damaged, do not dismantle the entire coating. It is enough to cut out the damaged strip and replace it with a new one.

Average cost of glued cork floors: price per m2

The main criterion for choosing a floor covering is the manufacturer. The following manufacturers are considered the most popular and the best on the market:

- Wicanders;

- Corkstyle;

- Allied Cork.

Average price of cork flooring Wicanders:

| Collection name | Price, RUB / m² |

| Cork parquet | 1230 |

| Eco Cork | 1340 |

| Crackle | 1400 |

| Nuances | 2000 |

| Personality | 2050 |

| Identity | 2050 |

| Exotic | 3700 |

What is the purpose of placing a technical plug on the floor

The technical plug is made from production leftovers. Therefore it is not used as a floor finish. The main function of this material is to eliminate defects by filling (granules) or preparing the surface for laying the laminate. In the second case, the cork sheet is used as a backing that levels the base.

The technical material comes in several forms:

- Granules.

- Rolls.

- Plates.

In addition, technical material is used to create additional sound and thermal insulation.

Technical traffic jam cost:

| The form | Size, cm | Material thickness, mm | Price, RUB / m² |

| Roll | 100x1000 | 2 | 104 |

| 3 | 163 | ||

| 100x2500 | 4 | 235 | |

| Plate | 91.5x61 | 4 | 323 |

| 6 | 464 | ||

| 8 | 547 | ||

| 10 | 666 |

Which is better to buy a cork floor: adhesive or floating

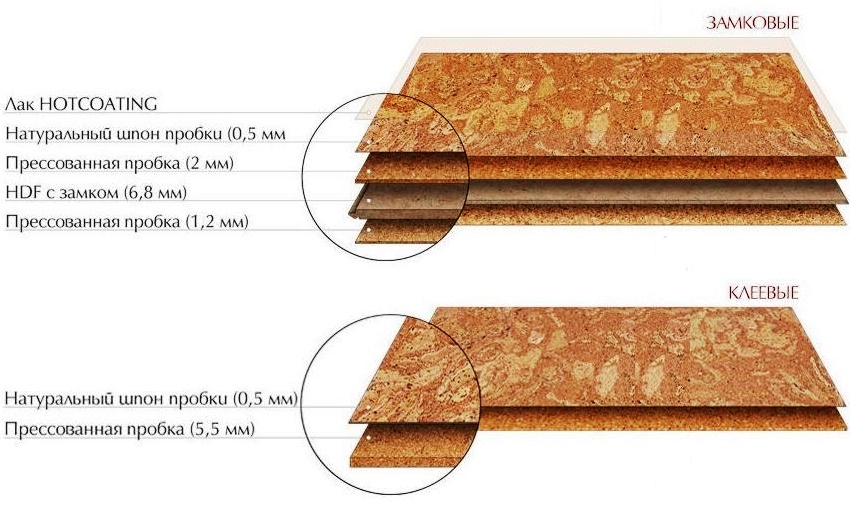

Adhesive and interlocking floors differ from each other not only in their structure, but also in properties.

An adhesive floor panel consists of the following components:

- bases made of compressed agglomerate obtained by gluing;

- wood veneer as a decorative coating;

- a thin layer of varnish or protective vinyl covering, which gives the panel a matte or glossy surface.

Advantages of adhesive coating:

- It is not afraid of the influence of humidity and temperature extremes, as well as contact with water.

- Installation in rooms with high levels of humidity or lack of heating is allowed.

- The material is easy to cut, which facilitates the installation system.

- An extensive selection of design solutions (the coating can not only be tinted, but also create mosaic patterns on its basis).

- It is not necessary to use sills in the joint areas between the cork floor and the base covered with parquet or tiles.

Disadvantages of adhesive coating:

- Installation requires careful preparation of the base. Any changes in the surface will be conspicuous after the coating is laid.

- Purchase of varnish and glue is required.

- High-quality installation of the coating can only be done by specialists.

Note! The price of cork interlocking floors is much higher than that of adhesive floors. However, the installation of the latter requires the participation of specialists and the purchase of additional materials, due to which the total cost of the coating increases significantly.

The locking plug consists of:

- pressed agglomerate;

- HDF or MDF fibreboard equipped with mounting spikes and grooves;

- a protective layer of the agglomerate;

- veneer finish;

- protective layer of vinyl film or varnish.

Advantages of castle floors:

- There is no need to cut the material. No varnish or glue is required for installation.

- It is not necessary to carefully level the base. A height difference of 2 mm per 2 m surface is allowed.

- A simple installation system allows you to lay the cork yourself without the help of specialists.

- Dismantling and reuse of the material in another room is possible.

The locking plates are not afraid of high air humidity, but provided that this indicator, like the temperature, is constant. The coating can withstand contact with water for no more than 24 hours. After that, it is necessary to dismantle the floors and dry its elements.

Choosing cork floors: owner reviews, pros and cons

When choosing a floor finish, you should pay attention to the quality of the cork agglomerate. Some manufacturers add cheap impurities, such as shavings, to this layer to reduce production costs. As a result, the material turns out to be tough, while it wears out faster. For this reason, it is worth giving preference to clean products, even if it is a compressed cork and its cost is high.

Adhesive floors have their drawbacks. Even quality products from manufacturers may have minor defects. Most often, there are errors in dimensions, which is why the strips have different sizes. As a rule, they are small and are 1 mm in length or width. This indicator is considered normal, since due to the elasticity of the material, this disadvantage is compensated for during installation: the panels are compressed and the joints are tight. Sometimes planks with different thicknesses come across. This defect is much more problematic.

Helpful advice! If the batch contains strips with different thicknesses, the material will have to be re-sorted. It is better to lay thin elements in those places where the transition will not be so noticeable. Thick ones can be corrected by removing excess thickness around the edges with sandpaper.

Since cork is a natural material, there are often defects on the surface such as cavities, an ugly color transition, as well as manufacturing defects (veneer peeling or its partial absence). Before proceeding with the installation, you should carefully inspect the material, glue the exfoliated places, and place the defective strips where they will not be so noticeable. Castle floors are more advantageous in this regard, because the protective coating hides all the flaws.

Considerable importance is given to consumer reviews when choosing a cork flooring for floors. The opinion of buyers who have already tried this type of finish can be informative and decisive.

Strengths and weaknesses of cork floors: customer reviews

Cork finishes are not as popular as other finishes that are already well known to customers. Those consumers who nevertheless ventured to purchase this material share their reviews on cork laminate on the forums.

“At first we considered laminate flooring, but we found it too noisy and slippery. A dog lives in our apartment. I don't want to listen to the constant clatter of claws. We couldn't afford parquet. Therefore, we decided to take a closer look at the cork coating. The material, of course, cost more than laminate, but its high price was outweighed by numerous advantages. The coating turned out to be soft and quiet, and most importantly, warm. The cork was laid on the floor on its own, without calling the master at home. Bribed by the naturalness and environmental friendliness of this material. I absolutely do not regret my purchase and recommend it to everyone. A more comfortable finish simply cannot be found. "

Svetlana Ezhova, Moscow

“I have a twofold attitude towards cork floors. The material really has many useful properties. This is beauty, naturalness, and the ability to keep warm. On the other hand, it is not practical. The cork swells due to water, so the seams between the slabs can swell. I also cannot recommend this coating to those who have children in the house, because the surface of the cork is very sensitive to damage. The material requires careful handling. If you are ready to take care of it properly, the cork will not disappoint. "

Maria Korotaeva, St. Petersburg

To protect the natural coating from external mechanical stress, the floor should be treated with varnish, sealant or wax impregnation

What cork floors look like in the interior: photo

The use of this coating in the interior can be varied. In the photo, cork floors look prestigious and original, especially in the living room, bedroom and study. It is allowed to use in the children's room, but subject to careful treatment. The coating can be made in natural colors (natural) or painted in any shade of the palette.

The most common natural colors are:

- yellow;

- ocher;

- light brown;

- red brown;

- mustard, etc.

Note! When choosing the color of the future coating, it is imperative to take into account the design and color of the furniture.

Can cork floors be used in the bathroom and kitchen

In any premises where the microclimate assumes a constant change in temperature, the cork will collapse and crumble. These rooms include not only the kitchen, but also the bathroom, which is also characterized by a high level of humidity. Temperature changes provoke the appearance of gaps in the coating. As a result, water starts to seep into the cork, causing the coating to peel off. It is also not recommended to use a cork on the balcony and in the hallway.

Problem areas are usually hidden from view:

- under the bathroom;

- behind the skirting board;

- under the sink;

- under the washing machine;

- behind the outdoor furniture.

It is in these zones that water vapor settles and condenses, destroying the coating. As an alternative to protecting cork floors in your kitchen or bathroom, you can use a quality waterproof lacquer. However, it does not prevent mucus blisters. Under the influence of moisture, they appear under the top layer of the coating and spoil its appearance. In addition, the cork has no antiseptic properties, so a microbiological environment can form under it.

Experts do not recommend using cork in the bathroom. With regard to the microclimate, the kitchen has more gentle conditions, although even there the floor will undergo serious tests - constant pollution, spilled liquid (juices, coffee, tea), etc.

How to install slabs of cork flooring

Cork reacts sensitively to moisture levels, contracting and expanding depending on room conditions. Therefore, before starting work, it is advisable to hold the packaging with the material for several days in the room where it will be laid. During this time, the humidity level stabilizes. A technical roll cork can be used as a substrate for the coating. The optimum thickness of this material is 2-3 mm. The wall should be retreated by 1.5 cm. The technical plug is laid on a waterproof film over the concrete screed.

Installation of the first row starts from the wall opposite the entrance door with a 5 mm distance. If the material needs to be cut, the cut is made from the side where the ridge is. Do not touch the groove. It is advisable to use a circular saw or electric jigsaw to cut the plug. It is better to refuse a hand tool, otherwise the cork will crumble. The set of the second row is carried out with an offset of half the tile. A wedge (cork) and a rubber mallet should be used to fit the elements.

Important! It is imperative to leave an indent of 1-2 cm from the wall. Like any natural material, cork undergoes deformational changes, so you need to leave a little space for expansion.

After that, the coating is treated with several layers of varnish. The composition can be matte or glossy. The joint area near the wall is masked with wooden skirting boards.

How to properly install glued cork floors

Before work, the material must be sorted by selecting thinner elements. Thick strips should be sanded with sandpaper. The coating is laid on the base in the form of a concrete screed. It is allowed to install the cork on old linoleum, but on condition that its surface is free from swelling and damage. The main thing is that the surface is flat, smooth, without dirt and debris. To level the base, you can use moisture resistant plywood or fiberboard.

If there are slight differences on the surface, it is advisable to apply a coat of primer. It will not only eliminate minor irregularities, but also increase the adhesion of materials. The recommended level of air humidity in the room is 65%, and the temperature is at least 18 ° C.

In this case, installation work should be started from the middle of the room. To simplify the process of laying the coating, it is advisable to apply markings on the surface of the base. A cord is suitable for this. An adhesive composition is prepared according to the instructions. It is applied to the board surface using a roller. After that, the element is pressed tightly against the base, previously greased with glue. Use a fine-toothed spatula to apply the composition.

Excess glue must be removed immediately. There are special substances designed for these purposes - solvents. You need to act very quickly. Long-term contact of the solvent with the coating is not allowed. In order to press the tile more tightly to the floor, its surface must be rolled with a heavy roller (metal).

After all installation work is completed, the room must be ventilated. It takes at least 36 hours to dry the coating. Then the cork surface is thoroughly cleaned of debris and opened with 3 layers of varnish. After 5-7 days, the floors can be used.

The advantages of cork as a finishing material are obvious. With proper care, the coating will retain its attractiveness for a long time. A wide range of colors and the ability to apply prints allow you to create a unique room design.And provided that all technology requirements are met, cork floors can be laid on your own and you can save a lot of money on this. Installation of the adhesive coating is more complicated in execution. But this type of floor is perfectly combined with parquet and laminate.