Which floor screed is best for concrete floor slabs and wood floors? In the process of construction and renovation work, it is very often necessary to replace old wooden creaky floors with new reliable and durable ones. It is not so easy to do this without a screed. There are several different types of device for this leveling sub-floor.

Content [Hide]

What are the types of screeds

Many have heard of such a concept as a floor screed, but not everyone knows its purpose. In the construction literature, it is defined as a leveling cement-sand layer, laid on the floor, on which the topcoat is laid. Today, not only cement and sand are used when installing screeds. There are other, more modern materials. Which floor screed is better - everyone can understand for himself only by studying the features of all its types.

In addition to leveling the surface for laying the topcoat, screed has a number of other functions:

- increased surface rigidity;

- creation of hydro and thermal insulation;

- organization of the desired slope for water drainage, if required by the purpose of the premises;

- disguise of engineering and electrical networks and communications.

Consequently, any of its types must have all the qualities necessary to perform the above functions. Which floor screed is best for you? Builders distinguish 4 types of screeds: wet, semi-dry, dry and self-leveling. The choice dictates the type and purpose of the room itself, in which it is planned to make the screed.

Purpose and features of the wet screed device

This type of screed owes its name to the fact that a large amount of water is present in the solution. Among the components of the solution are: cement grades from M200 and above, fine-grained sifted sand, water. Then the surface of the screed is processed using special solutions that give strength to the monolith.

Related article:

Floor screed: how to do it using various available methods. Methods, types and technology of floor screed device. Wet, dry and semi-dry types of floor screeds. Properties of different types of screeds.

Consider in more detail the composition of the mixture for making a wet screed for the floor. What is the best proportion to choose, see below. A guaranteed good screed will turn out if you take Portland cement of the M300 or M400 brand, mix it with sand and dilute with water in a ratio of 1 to 3.

A better quality screed is obtained by adding plasticizers that bind cement and sand particles into a solid monolith. The layer thickness when pouring must be at least 2 cm. Otherwise, the surface will crack.

This is a classic version of the do-it-yourself floor screed device for beacons. Videos of just this kind of technology dominate the web. It is suitable for any topcoat and for creating a "warm floor" system. The disadvantages include: laboriousness of installation, the presence of wet works with a large amount of water, long (up to 3 weeks) drying of the surface, the need for constant wetting to avoid cracking.

Useful advice! When installing an electric underfloor heating under a concrete screed, plastic fastening clamps of the screed can be used to attach the heating elements to the fittings. They are easy to cut and hide under the concrete base.

Semi-dry and dry screed technology

From the name it is clear that in semi-dry technology, the use of water is greatly reduced or completely limited. There is a lot of sand in the solution, which allows the concrete to harden very quickly, but, unfortunately, at the expense of strength. Most often, a semi-dry screed is used in apartments.

When deciding which floor screed is better, you also need to know about the completely dry method of screed construction. In this case, no water is used at all. The overlaps are covered with dry mixtures, which are leveled and covered with sheet materials on top, such as plywood or gypsum fiber. Such a screed has a small mass, which allows it to be successfully used in a private house on wooden floors.

Useful advice! The device of a wet screed is more justified in non-residential premises: garages, industrial buildings, shopping pavilions. It is more durable and able to withstand heavy loads. Dry screed methods are used in apartments and private houses.

Screed based on self-leveling compounds

This is a new modern way of creating a flat surface for the installation of topcoats. Self-leveling mixtures are also called self-leveling floors... They can be based on a cement-sand mixture with the addition of polymers or completely polymeric.

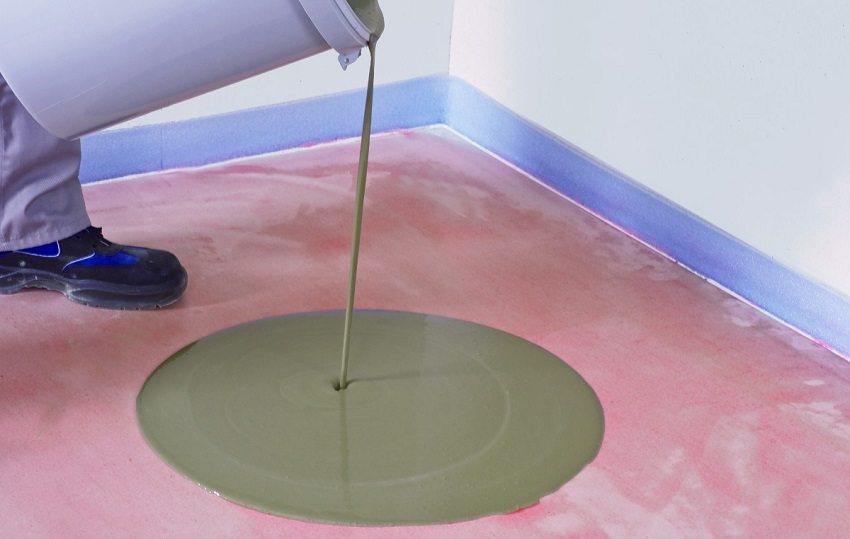

The main feature of self-leveling floors is the ability to spread over the surface in a thin layer under the influence of gravity. The solution fills in all irregularities, and its surface becomes absolutely parallel to the horizon level.

The self-leveling screed solution spreads under its own weight and fills all irregularities, and its surface becomes absolutely horizontal

A self-leveling floor does not need any help to spread it over the subfloor. It is enough only to roll it with a spiked roller to remove air bubbles. This becomes possible due to the high fluidity of the solution itself. Another advantage is that the self-leveling floor has a thickness of 35 to 100 mm, which makes it lightweight.

A floor made of self-leveling mixtures is most often used not as an independent screed, but as an additional coating on a concrete base. All this thanks to its perfectly flat surface.

Which floor screed is better

Having considered several options for a leveling surface device, you need to determine for yourself which floor screed is better. It is impossible to unequivocally answer this question, since the choice of the type of alignment depends on the room in which it is done.

Do not make a dry screed in bathrooms, toilets and lavatories, since there is always a risk of flooding in these rooms, which will damage the entire layer with the appearance of mold and mildew in it.The use of a wet screed in residential premises is also not justified, since it entails large financial and labor costs. The time for its complete drying is very long, and it is dangerous to lay the topcoat on an incompletely dried base.

On the contrary, the use of a wet screed in garages and other non-residential buildings is simply necessary, since none of the other screeds possesses such density and hardness. Indeed, in industrial premises, heavy equipment often moves on the floor and bulky and massive equipment is installed on it.

A dry screed is very good for wooden floors in private houses. It does not use water, which has such a negative effect on wood. Absolutely dry assembly guarantees the durability of all timber components.

The choice of the method of screed for the floor depends on the purpose of the room in which it is equipped

Useful advice! Experienced builders use a combination of two types of screeds in the production of repair and construction work. Most often, a wet or semi-dry screed is combined with a self-leveling floor, which makes the surface much smoother.

Thus, it is possible to determine which floor screed is better only in the context of understanding which room will be covered with it and for what purposes it will be used in the future.