The bedroom is the place where a person spends most of the day. It is here that a person draws conclusions about the day he has lived and sets himself up for the next working day. The bed is rightfully considered the centerpiece of any bedroom. The quality of the night's rest depends on what it will be. A solid wood bed is considered not just an ageless classic, it is durable and elegant. The wooden bed is easy to fit into any interior and design style.

Content [Hide]

- 1 Highlights to look for when choosing a solid bed

- 2 Solid wood bed: the most popular material options

- 3 Wooden double bed: how to choose the right size

- 4 How to choose children's beds made of wood: basic requirements for products

- 5 How to make a bed out of wood with your own hands: materials and stages of work

Highlights to look for when choosing a solid bed

A solid bedroom is rightfully considered an indicator of wealth and decoration of any home, especially if it is made of timber or by combining wood and natural stone. If wood was used in the manufacture of this piece of furniture, the bed is considered environmentally friendly, and it does not matter which species was used for this.

Important! One of the main criteria when choosing furniture for a bedroom made of wood is a solid frame, which serves as the basis for any bed.

The most reliable version of the frame is considered to be a product with four side panels that play the role of key supports to which the backs are fixed. The headboard is a must, while the footboard can be neglected, especially if the room is not large. Also, the foot will interfere with people who are taller than average.

The best basis for a mattress is considered to be jumpers - wooden slats, which provide comfort for sleeping. The minimum number of lamellas should be as follows:

- 15 pieces - for arranging a single bed;

- 30 - for a double or one and a half bed.

It should be borne in mind that the more often the slats are placed, the more comfortable the bed is. The maximum distance between elements should not exceed 3.5 cm.The best are beds in which this distance is 1.5-2 cm. Products with a lamellar frame can be equipped with retractable structures or a lifting mechanism.

When choosing the length and width of wooden beds made of solid wood, it is necessary to take into account not only the dimensions of a person, but also the parameters of the room. If a product of non-standard parameters is required, it is better to order a bed for individual production. However, it should be taken into account that in this case one cannot do without individual tailoring of the mattress. Most often, when choosing a color, preference is given to classic options and beds are purchased that have shades of oak, alder, walnut. In addition, the following colors are considered popular:

- wenge;

Some people choose a natural wooden bed not so much because of its appearance, but because of its beneficial properties.

- sandalwood color;

- mocha;

- anegri.

When designing modern interior styles, such as high-tech, modern, minimalism, preference is given to frames painted in white. If we are talking about classic styles, it is important to purchase an antique bed, which combines dark shades and unusual carved headboards. When choosing a height, you need to focus on the height and age of the person who will use the bed.

The main advantages and disadvantages of adult and children's solid wood beds

If you look at photos of wooden beds, you will certainly notice the attractive and reliable appearance of the products. Whatever solid wood is used in the manufacture, the bed will always have an impeccable appearance, especially if it is properly looked after. In addition, many types of wood, being in a warm room, emit useful ethers, which form a unique aroma and a special microclimate in the bedroom. Other positive aspects of using natural bed material include:

- naturalness. The array does not need to be covered with a special varnish and subjected to additional painting, so the furniture is made without the use of toxic elements;

Natural materials have been very popular at all times due to their safety and environmental friendliness.

- durability. If you take care of the bed, make sure that it does not loosen, eliminate minor breakdowns in time, the product will last for more than a decade;

- positive energy. A person who has acquired a wooden bed always sleeps soundly, which has a positive effect on the nervous system;

- attractive appearance. The original natural texture of wood makes each bed unique and unique;

- high manufacturability. If the bed is made of soft wood, it is easy to decorate the product yourself using a variety of carved elements. Carved wood beds will become an accent item in any bedroom;

- ease of assembly. If the bed has acquired a certain backlash and loosened a little, it can be disassembled and all fasteners tightened, which cannot be done with a metal bed made of a solid frame;

- increased resistance to damage. The wood is resistant to chips and scratches and retains its impeccable appearance for a long time. In any case, if defects appear, the surface can be sanded and coated with oil, after which the product will look like new.

It is interesting! Wooden furniture makes the atmosphere in the bedroom more warm and cozy.

Despite all the advantages, wooden beds also have some disadvantages, which include:

- High price.The price of a bed made of solid wood is several times higher than the cost of analogues made of MDF and chipboard, because the material itself and processing will cost more.

- Large weight of the finished product. Wooden furniture is heavy and bulky. Before installing such a bed in the house, you need to be sure of the reliability of the floors.

- Special operating conditions. The tree does not like temperature fluctuations, and also tends to shrink, especially if the primary material has not been sufficiently dried. Changes in humidity may cause cracks.

- Burnout ability. When exposed to open sunlight, furniture may fade a little, but it should be borne in mind that facades made of chipboard and MDF also lose their color over time.

Varieties of arrays for the manufacture of wooden beds

When choosing an array for a bed, you need to know that there are several different types, which differ in the type of wood, wood species and method of processing. The array itself is a sheet of wood that has undergone preliminary processing - it can be both beams and boards. Depending on the production technology, there are 2 options for arrays.

Related article:

Wrought iron beds: photos of original ideas for an elegant design

Types of headboards. Children's models. White wrought-iron bed. Making metal products with your own hands

Whole. Furniture is made directly from a piece of wood that does not have knots or cavities. This material is also used for the manufacture of doors, windows, as well as for the production of flooring. Finished pieces of solid wood furniture are very expensive due to the high cost of high-quality and intact wood.

Glued. To understand what this type of solid wood is, you need to pay attention to the principle of its manufacture. Fragments of solid wood are also used in the production of furniture from glued solid wood. However, in this case, a material is used, which is characterized by the presence of some defects, for example, it can be cracks, chips, holes from knots.

If there is any damaged material, the piece of wood is sent for sawing. Lamellas are made from it, sifting out damaged areas. The remaining parts are glued together using special glue, resulting in solid sheets, similar to plywood. Whereas classic plywood is produced by gluing sawdust, the glued array consists of solid wood.

Solid wood bed: most popular material options

To understand which bed is best, you need to study some of the characteristics of wood. The solid wood is a completely natural raw material. No other materials are used for the manufacture of such furniture. When choosing an array of bedrooms, you need to pay attention to the following tree parameters:

- hardness;

- impact strength;

- density.

Hardness and density indicators are considered the main criteria for the quality of wood. The higher the density value, the longer the product will last. There are 3 types of density:

- low;

- medium;

- high.

According to the criterion of hardness, wood is divided into soft, hard and superhard species. Naturally, the higher these indicators of wood, the higher the price of the finished product, because the complexity of the work depends on this criterion.

Softwoods, which include pine, linden, aspen and spruce, are the most malleable materials, and products made from such species are considered more affordable.

It is important to understand that soft rocks require more gentle and careful handling to avoid the rapid appearance of chips and scratches. Therefore, if you need a bed for a children's room (an option with drawers or a bed from an array with a lifting mechanism), it is better to choose harder rocks that are resistant to mechanical damage, which include:

- birch;

- beech;

- ash;

- nut.

Beds made of natural wood of these species are more durable and reliable, although this fact does not exclude the need for careful handling of furniture. Ready-made options can well be left without processing or painting, since the tree has a beautiful pattern. The only thing that needs to be done is to cover it with a special colorless varnish, which will further emphasize the special texture.

The most expensive and noble species is oak. Such furniture always attracts attention, is considered an indicator of wealth and a manifestation of elegance. The cost of oak products is always much higher than the price of furniture made from other types of wood. The next place in cost is taken by beds made of solid birch and beech. The cheapest options are made from pine, less often from spruce. The price also depends on the size of the bed, according to the standard, the following options are distinguished:

- single beds. The width of the berth varies from 80 to 100 cm, the length is 180-200 cm;

Hardwood beds have a very high strength, but due to the complexity of the technological process, they are much more expensive

- one and a half. The width is not more than 150 cm, the length is also standard - up to 200 cm;

- double. The width ranges from 140 to 200 cm, the length is 190-210 cm.

Depending on the wishes of the customer, the parameters can be changed at his discretion. And also, it should be additionally provided for the presence of a lifting mechanism, a headboard and a footboard. All of these elements are final and form the price range.

Pine bed: the main advantages of the material

Pine is considered to be one of the most demanded materials in furniture production due to its low cost and ease of processing. The main characteristics of this material include the following:

- average density - 540 kg / m³;

- density limits - 300-860 kg / m³;

- tensile strength - 100 N / mm²;

- longitudinal shrinkage - 0.4%;

- bending strength - 80 N / mm²;

- compressive strength - 45 N / mm².

Pine is resistant to rotting and protected from fungal infection. The material is popular in the production of wooden beds and other furniture elements due to the small number of knots, as well as the almost identical trunk diameter. The high strength of the pine timber makes it possible to manufacture structures of various shapes. In addition, this material has an attractive appearance, and also has sound and heat insulating properties.

It is interesting! The positive aspects of using pine for the production of beds include not too much weight of the finished product.

Pine beds are most commonly found on the market because this tree is the most common among other species. However, it should be borne in mind that, due to the high resin content in pine wood, when heated, resin can be released from the boards, which can stain bedding.

Reasons to choose a solid pine bed

Pine beds have an attractive appearance, since the frame and its details can be decorated to match any type of wood.Due to the fact that pine lends itself well to processing, it will not be so easy to distinguish a bed from products made of oak or beech.

The second advantage is the fact that the pine wood itself looks beautiful and can be left in its original form. Shades of sunny amber will fill the bedroom with a pleasant palette, make it warm and cozy. The natural colors of the pine boards are unobtrusive, and the ornate pattern of the wood structure does not bore and pleases the eye.

Another plus is the environmental friendliness of the beds, in the manufacture of which such a toxic substance as formaldehyde is not used, which is used to create chipboard sheets. In addition, pine material contains phytoncides with anti-allergic properties, which is especially important in the manufacture of beds for children's bedrooms.

Furniture manufacturers prefer to use pine for making beds, because this breed is soft, due to which it is easy to create a beautiful pattern on it. This will allow you to make an original carved bed, which, if desired, can be tinted, varnished or left in its natural color.

An important criterion for choosing a pine bed is its price, which will be half the cost of an oak bed. If the pine used for the production of the bed has been competently processed and dried, then the finished product will not be afraid of either moisture or dryness.

However, manufacturers do not recommend installing the bed in rooms in which temperature readings vary greatly. Also, before buying, you should take into account that there should be no small holes on the side parts of the bed, which may indicate a tick damage to the wood, which will significantly reduce the strength of the product.

Solid oak bed: the main decoration of any bedroom

A bedroom made of oak is considered an elite option, which differs not only in its high cost, but also in the rather large weight and size of the finished structure. This furniture requires a lot of space, so you should not consider the option of such a bed for a small bedroom, otherwise there is a risk of cluttering up the useful area of the room.

Oak has long been known for its durability and increased strength. Strong and hard oak wood is not susceptible to high humidity, and, unlike pine boards, parasites are extremely rare in it.

Solid oak is characterized by an attractive natural structure, which can be enhanced with a stained finish. After applying the product, the wood will darken and take on a rich dark red hue, which can often be seen in classic interiors of natural wood bedrooms. Features of oak beds:

- Significant disadvantages of oak beds are their high price and a long time required for their production.

- The main difference between oak and pine wood is the absence of resinous secretions.

- Finished products do not crack even at temperature extremes.

Wooden double bed: how to choose the right size

First of all, the choice of bed sizes depends on the size of the room. If the bed is too large, there will be no room for comfortable movement around the room and there is a risk of constant tripping over the legs.

Helpful information! For a comfortable sleep, an adult of average build requires 70 cm of berth. If a person has a large physique or prefers sleeping on his stomach with his arms spread wide, he will need more free space.

If the parameters of the bedroom allow you not to save on size, then a double bed made of solid wood is chosen based on the parameters of the person who will constantly use it. The number of people and sleep habits are also taken into account. For example, if you choose a bed in the parent's bedroom, it is better to immediately give preference to wide options, especially if the children are still young and do not mind hanging out with their parents.

Among the standard options for double beds made of wood, products of the following sizes stand out:

- 120 × 200 cm - is the smallest version of a double bed, it is also called one and a half size;

- 140 × 200 - double "standard";

- 160 × 200 - large "king size" bed;

- 180 × 200 - super king size;

- 200 × 200 - imperial bed.

All the listed sizes are considered standard, so it is easy to buy the right mattress and bedding for them. If you decide to make a double bed out of wood with your own hands, then you must also adhere to the generally accepted standard sizes. The maximum deviation should be no more than 1-2 cm, otherwise the mattress will have to be made according to individual parameters, which will cost 30-40% more than standard models.

How to choose children's beds made of wood: basic requirements for products

Wooden beds are made for children of different ages. These can be classic cribs for babies, hanging rocking chairs, playpen beds or transformers. For teenagers, single or one-and-a-half options are more suitable, and children of older preschool and school age will like bunk structures, cottage beds and attics.

If you choose a wooden bed for a newborn and a child under 3 years old, you should pay attention to models with high sides and an adjustable bottom. The best option is a transforming bed, which can be adjusted to the age of the child. Typically, such products are designed to be used from birth to 6-7 years. An older child needs to buy a bed for growth, so the standard size 80x190 cm is quite suitable.

Wooden beds, in addition to being considered ecological, are also characterized by increased strength. By installing a wooden bed in a child's bedroom, parents can be calm, because wood has the ability to "breathe" and is much more pleasant to the touch than iron. When purchasing cots, it is important to follow these steps:

- assess the reliability of the structure;

- check that the stairs to the top are safe and reliable, and also have a slight slope;

- measure the height of the side: if the berth is located on the second tier, if necessary, it is worth fixing an additional stop;

- check the bed for splinters.

How to make a bed out of wood with your own hands: materials and stages of work

To start making furniture from an array with your own hands, you should draw up a detailed diagram. To do this, you need to decide in advance on the size and model of the bed. You must first select the size, height and thickness of the mattress.

Important! Craftsmen advise purchasing a mattress before starting the manufacture of the bed, so that later there is no need to adjust the base to the size of the product.

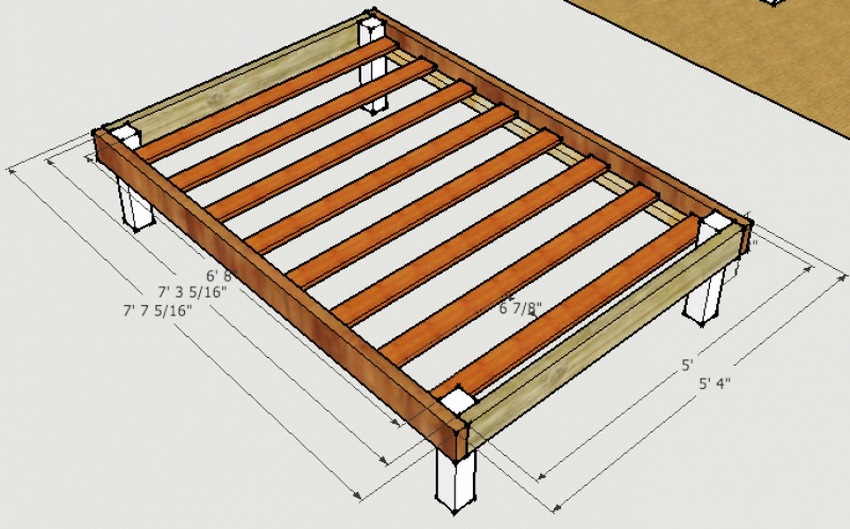

Now you need to understand how to make a bed out of wood with your own hands. To do this, you need to form 2 sidewalls, the front and rear, as well as a frame on slats or slats and 4 legs.If a large bed is planned, it is better to provide for the presence of two additional legs in the central part. During the manufacture, you will need the following materials:

- board;

- timber;

- slats;

- self-tapping screws;

- joiner's glue;

- jigsaw;

- tape measure and pencil;

- stain and varnish.

In order for the furniture to be reliable, we assemble corner joints using L-shaped hardware and self-tapping screws

After purchasing all the materials, it is necessary to apply the correct marking and sawing. In this case, the sawing can be performed at the place where the material was purchased. If this process is carried out independently, you should draw a line using a level, and after making one part, use it as a template. In total, you should get 2 side boards, back and front walls. All ends are processed with sandpaper.

To prepare the walls for fastening the supporting beam, the front part is divided into 3 equal segments in length and markings are set, the same actions are performed with the rear wall. When calculating the depth of the frame, craftsmen are advised to take into account the thickness of the mattress, slatted floor and load-bearing longitudinal beams. Taking into account the total value, which generally depends on the height of the selected mattress, a line is beaten around the perimeter, along which the support bar will then be attached. Then this bar will become the basis for securing the lamellas. If desired, you can additionally consider the presence of a footboard and headboard.

To create a bed out of wood with your own hands - may not be the easiest decision, but definitely the most profitable

All ready-made components of the frame are covered with a stain, after drying of which 2 layers of quick-drying varnish are applied. Then the parts are connected to each other, and lamellas with a minimum step of 2-4 mm are fixed onto the finished frame made of beams, on which you can then lay the mattress, having previously made sure that the structure does not get dirty.

Wooden beds in the bedroom have always looked and will look beautiful. The natural design of wood is difficult to fake, and even modern materials that imitate wood are unable to recreate it. Due to the fact that each type of wood has its own aroma, the bedroom is filled with a special atmosphere, comfort and warmth.