Closers for kitchen cabinets are represented by special mechanisms that are installed on furniture doors and ensure their smooth and silent closing. Such details help to preserve the integrity of the furniture surface, eliminate the likelihood of cracks and paint chips, being the key to the durable operation of the kitchen set. The principle of operation, types and rules for installing products can be found in this article.

Content [Hide]

- 1 Closers for kitchen cabinets: functional purpose of mechanisms

- 2 Advantages and disadvantages of regulating fittings for kitchen cabinets

- 3 Varieties of closers for the kitchen according to the principle of operation and mounting option

- 4 Lifting mechanisms: characteristics and types of products

- 5 Varieties of furniture hinges with kitchen closers and drawer mechanisms

- 6 How to install furniture hinges with a door closer on a kitchen cabinet

- 7 Adjusting the closers for kitchen cabinets

- 8 How to repair a door closer with your own hands

- 9 Overview of manufacturers of high-quality kitchen cabinet fittings

Closers for kitchen cabinets: functional purpose of mechanisms

For convenient and comfortable operation kitchen cabinets must be equipped with an automatic door closer system. The mechanism is based on a special spring, which is located inside a metal capsule. It can be filled with oil, silicone filler or special liquid. At the moment of impact on the door, pressure is created on the closer stop. The fluid inside the capsule covering the spring flows into the back of the sleeve and is retained by a double gland system.

Due to the presence of a special valve, the closing speed of the door can be adjusted by narrowing and widening the outflow channel. By acting on the kitchen door, the closer is activated, the control valve expands and the outflow channel decreases. The piston slows down, which ensures smooth and silent door closing.

Gas closers are mainly installed on cheap lockers. The principle of their work is as follows. At the moment of impact on the doors, they are quickly closed until a certain moment, after which the closer begins to work. The mechanism capsule contains gas, the pressure of which can vary. The door closer provides a slow and silent door closing, but itself is fragile and short-lived.

Advantages and disadvantages of regulating fittings for kitchen cabinets

Furniture closers for cabinet doors contribute to a smooth and slow closing of the facade, which eliminates the possibility of deformation and damage to the structure. The doors close tightly enough, their spontaneous opening is excluded. Even in the event of a breakdown of the mechanism, you should not fear for the possible leakage of liquid or oil from it. High-quality door closers are able to withstand significant mechanical stress without losing their technical and operational properties.

Furniture closers are produced in a wide variety of species, which allows you to choose the best option for a product of the required size and acceptable cost. Due to the simplicity of the design, the mechanism is easy to install yourself. There are models that have an additional function, which makes it possible to fix the door in a certain position at a certain angle. These are the characteristics of Blum kitchen cabinet closers.

Important! The choice of a quality device is the key to its durable operation.

The disadvantages of the mechanism include not very attractive appearance of the products. In order for the device to work correctly and smoothly, it is worth following certain rules and requirements for its installation. The design also needs careful adjustment, which will allow it to cope with the task later. It is advisable to use oil closers in heated rooms, since at low temperatures the oil becomes viscous, which negatively affects the operation of the mechanism.

Varieties of closers for the kitchen according to the principle of operation and mounting option

According to the method of fastening, closers for cabinets can be cabinet closers, which are fixed directly to the inner wall of kitchen furniture using self-tapping screws, or looped, that is, built into the hinges or located between them. The latter version of the products is considered more reliable and durable, but it is not used for roll-out structures. There is a separate type of door closers that are mounted on drawers or drawers. Such products are equipped with a guide with a special spring.

In accordance with the mechanism of operation, the devices can be oil or gas. In the first case, the capsule with a spring is filled with gas, in the second - with an oily substance. Kitchen cabinet gas closers allow the door to move slowly to the middle of the path. They are often equipped with furniture hinges. The shock absorber is triggered at the last stage of door movement, softening the impact when they are closed. These door closers are recommended for use with hinged doors that open from below. They are characterized by low cost, but have a short operating life. This is due to the fact that the softening insert is in a tense position when the doors are closed.

Kitchen oil closers are more reliable and durable. They contribute to the smooth closing of the doors. It is ideal for swing and tilt systems. These devices are recommended for heavy doors and drawers.

Important! Oil closers need regular lubrication, which will contribute to a long service life.

Lifting mechanisms: characteristics and types of products

Lifting mechanisms are installed on the doors for kitchen cabinets that open up or down. Such devices are rarely used for swing systems. The lifting mechanisms are characterized by reliability and durability. They are presented in four varieties: spring, oil-spring, gas and electric.

A common option is the spring system, which is simple in design. A strong metal spring pulls in or pushes out the kitchen cabinet door. The mechanism is characterized by practicality. If used correctly, it can work properly for a long period of time. The disadvantage of such a lift is the inability to fix it in any position. The doors will either be tightly closed or fully open.

The oil-spring lift differs from the previous version in the ability to carry out smooth movements. The spring is located here in a metal capsule and is filled with oil. The standard version of this lift is the diagonal model.

Gas lifts have gas in the piston chamber. When acting on the mechanism, a change in pressure occurs, which contributes to the smooth running of the closer. Such a product is fragile and has a short service life.

The newest and most expensive lift option is the electrical mechanism. It allows you to set the delay time, after which the door will close on its own, and fix the opening angle of the facade, which should be no more than 107 degrees. Blum electric door closers deserve due attention.

Varieties of furniture hinges with kitchen closers and drawer mechanisms

Furniture hinge closers can be standard, built-in or overhead. The first option is represented by a structure built into the shoulder connected to the bowl. The arm is distinguished by a specific spring shape, which indicates the presence of a closer. The devices built into the kitchen cabinet hinges allow you to adjust the speed of the door speed increase. Depending on the area and weight of the door, the door closing process will be faster or slower. It provides for partial or complete damping of the impact on the hull.

If it is not possible to replace the old hangers with hinges with a closer for cabinet doors, you can purchase separately overhead devices that will ensure smooth closing of the cabinet doors. The mechanism is mounted near the hinge directly to the shoulder of the product itself with a latch, or installed on the cabinet body.

A more simplified version of the overhead closer is the damper. It does not provide soft closing of doors. The product simply dampens, softens the impact of the facade against the body. The damper can be presented in two versions - a shock absorber or a bump stop. A shock absorber is a silicone, oil or gas mechanism that attaches to the side of the furniture. The bulging element helps to cushion the impact. The bump stop, which has the form of a mortise or overhead design, is represented by a silicone gasket, which, taking the blow, muffles the sound.

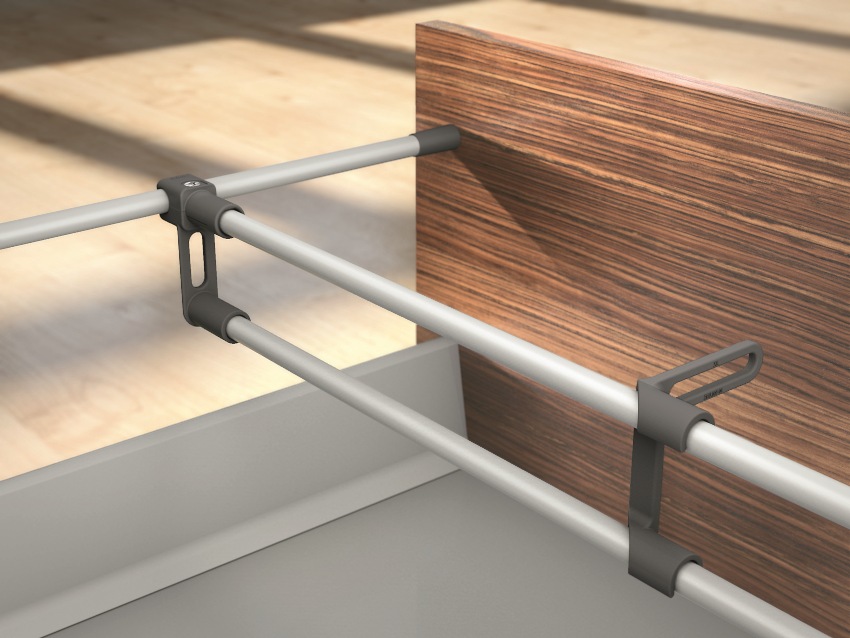

Closers for kitchen drawers are installed on metaboxes, made in the form of furniture boxes with a solid thick bottom, back and front of MDF or chipboard, and their side walls are made of metal. Such guides can be produced as separate components or integrated closers for kitchen drawers.

These shock absorbers can also be installed on boxes with fiberboard bottoms. However, when attaching them to the bottom, it is necessary to reinforce it. If the installation is carried out to the inner wall of the cabinet, the design of the mechanism will not make it possible to put the product on the lowest drawer. Ball systems with a built-in closer have proven themselves well.Despite the high cost of the devices, they can be installed in any place, which will ensure convenient and durable operation of the drawer.

The right approach to choosing a closer: basic recommendations

In order for kitchen furniture to serve for many years, it is important to approach with great responsibility the choice of closers for drawers and doors, which not only contribute to the convenient, comfortable and quiet operation of furniture elements, but also affect the aesthetic appearance and durability of the headset. There are a large number of devices, the type of which is selected based on the design and size of cabinets or drawers.

The first step is to determine how much weight the structure, which should be equipped with a closer, has. A weak mechanism is not able to withstand a heavy sash, which will lead to its rapid failure. Designed to fit large overhead cupboards, small doors close too quickly.

The method of positioning the closer is also important. The mechanism can be attached directly to the body, installed on hinges or between them. Be sure to pay attention to the manufacturer of the device. It is recommended to purchase a mechanism produced by a well-known company that has proven itself from the best side in the manufacture of accessories. The best are foreign brands. Blum kitchen closers deserve special attention.

Useful advice! If there is no desire to periodically adjust the operation of the mechanism, you should pay attention to self-adjustable door closers.

How to install furniture hinges with a door closer on a kitchen cabinet

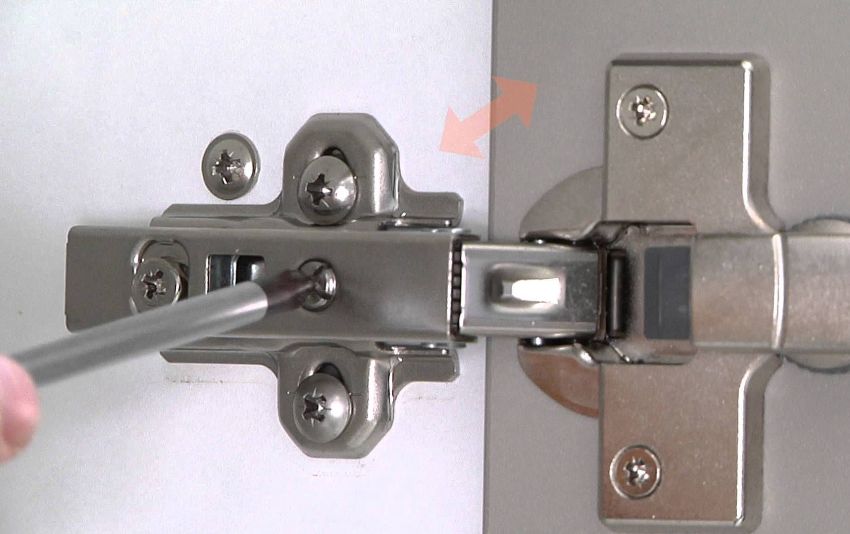

Installing hinges for a cabinet with a door closer is a simple event that requires a minimum set of tools in the form of a screwdriver, screwdriver, drill and fasteners. Before proceeding with the installation of the mechanism, you should study the instructions that come with any quality product.

If the hinges for kitchen cabinets are replaced with a closer of the same type and manufacturer, it is necessary to remove the old product, and put a new one in its place, using the same holes for fasteners. In the case of the initial installation of the product on a kitchen cabinet, the first step is to mark the holes for fastening. Using a drill, nests are made. Next, the product is installed by means of self-tapping screws.

After the hinges are securely fixed, the closer is installed. It must be inserted into the corresponding hole in the hinge. After a characteristic click has sounded, you can be sure of the correct position and reliable fixation of the mechanism.

A surface-mounted door closer usually snaps into the hinge in a certain place. Some options can overlap the shoulder or cup. If the door closer is installed near the hinge, it is necessary to make the corresponding holes for the self-tapping screws in the cabinet body.

Related article:

Closers for entrance doors: device, selection and installation of mechanisms

Types and principles of device operation. Self-installation of door closers. Rules for the regulation and operation of closers.

The method of fastening shock absorbers for kitchen cabinets is selected depending on the design of the product. It can be screwed to the inside of the case or cut into the end. In the first case, a Phillips screwdriver and 4x16 mm screws are used. The second method involves creating a hole for the shock absorber in the cabinet body using a drill with a drill of the appropriate diameter.

Important! When installing a large-sized door closer, the piston is attached to a stationary shelf, and the rest to the cabinet door. A small element is installed on a fixed part of the furniture.

The silicone damper is the cheapest option. It is glued to the body with a self-adhesive backing. The surface is pre-degreased with alcohol for better adhesion.

To install the closer on modules, you will need special screws, a screwdriver and instructions for the mechanism

Useful advice! The bump stop is best installed on the side that is close to the front handle.

The sequence of installation of the closer on the drawer

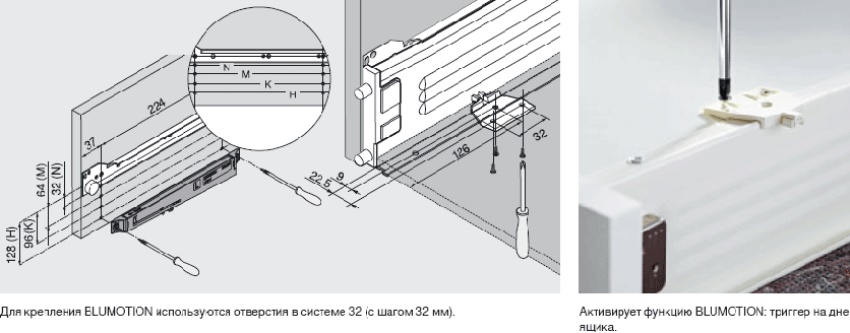

Installation of the door closer on the drawer is carried out according to the instructions that come with the product. It shows different installation options depending on the type of furniture element.

The first step is to measure the box. Further, according to the table displayed in the instructions, you must select the appropriate parameter, where the installation point of the main mechanism is determined. From the center of the roller guide, the distance indicated in the table is laid down and a horizontal line is drawn. Further on the marked horizontal it is required, according to the instructions, to postpone the distance from the edge of the facade. A thin drill is drilled at the target location. The drawer closer is applied to the intended positions and screwed into the drawer wall using self-tapping screws.

Important! The mechanism is fastened with the narrow side to the edge.

Next, an activator is mounted, represented by a small plate with a tongue, which clings during operation to the counterpart of the mechanism. It is important to install this element strictly according to the scheme so that the tongue looks out over the edge of the kitchen drawer. According to the scheme, marking is performed, holes are drilled into which self-tapping screws are screwed to fix the activator. After completing all the actions, the box is inserted into the roller guides. The operability of the device is checked, its operation is adjusted, after which the product is ready for further operation.

Important! For a narrow box, one-sided mounting can be used, and for a wide box, paired guides should be used.

Adjusting the closers for kitchen cabinets

After the furniture closer is installed, it is necessary to adjust its operation. The first step is to pay attention to the sliding speed of the mechanism. It should be optimal: not too fast, which may cause the door to hit the case, but not too slow.

Using the screw that is installed on the hinge, select the desired position. This element changes the throughput of the outflow channel, which leads to fluid overflow through the sleeve at different speeds. When twisting it, the speed gradually increases. Unscrewing the screw reduces the door speed. The screw can only be turned one turn in the appropriate direction. Performing two or more turns will damage the mechanism.

You should also pay attention to the tightness of the facade to the furniture. The adjustment is done vertically and horizontally with the corresponding screws on the kitchen cabinet hangers.

Important! Do not loosen the screws too much. This can lead to oil leakage and negatively affect the operation of the mechanism.

Closers for kitchen cabinets from Blum or other brands must be adjusted with the utmost care: every movement requires precision. Despite the high reliability and strength of the mechanism, it can fail or break under excessive pressure.

How to repair a door closer with your own hands

To extend the service life of the mechanism while maintaining its operational characteristics, it is important to know how you can repair the device yourself.The occurrence of defects in the operation of a closer for a cabinet door can occur as a result of an unfavorable microclimate in the room, which is associated with high humidity or temperature extremes.

The mechanism may fail due to a strong impact on it when the doors are quickly opened or closed, which is not provided for by the closer settings. Blocking the free movement of the doors will also negatively affect the mechanism. The closer will quickly fail if it is incorrectly selected in accordance with the weight and size of the door.

In the event of minor damage to the door closer body, which will lead to oil leakage, you can solve the problem with a simple sealant. If the crack is too large, a complete product replacement will be required. If there is not enough oil in the device, it is necessary to refill the closer with shock absorber fluid or synthetic engine oil. The substance is added through the hole for the adjusting screws after unscrewing them.

Periodically, you should pay attention to the condition of the bar of kitchen equipment for the home. If the part is covered with a layer of rust, this indicates that ordinary steel was used for its manufacture. It is necessary to clean the product from corrosive formations and treat the part with a special protective grease. In the event of a slight fracture, the defect should be eliminated by welding, followed by cleaning the seams to a perfectly even state. Use a hammer to eliminate bends and bends in the boom.

Important! The boom alignment must be done very carefully, without applying excessive force, as this could damage the integrity of the product body.

Overview of manufacturers of high-quality kitchen cabinet fittings

The guarantee of high-quality and durable fittings for kitchen cabinets is the choice of products from a popular manufacturer that has proven itself in the world market from the best side.

The most famous world manufacturer that produces high quality door closers is the Austrian company Blum. Products are made of stainless steel, which eliminates the likelihood of corrosion deposits. Special attention should be paid to lifting mechanisms that can be selected for any weight and size of the movable structure. The product range includes a line of drawer closers. One element is designed for a product weighing up to 25 kg. The price of Blum kitchen cabinets closers is in the range of 140-800 rubles.

The second most popular manufacturer is the German company Vaith Sagel, which offers a wide range of different types of door closers designed for luxury furniture. The price of the product varies from 300 to 1000 rubles. More affordable, but no less high-quality devices are produced by another German company Hettiсh. Most of the products are lifts and hinges with built-in door closers. You can buy the product for an average of 150-400 rubles.

Reliable and durable oil closers are manufactured by the German company Agoform. The price of the product is 200-900 rubles. Good products are offered by the Austrian manufacturer Siro. The price of hinges for cabinets with a closer is 130-500 rubles. Russian manufacturer Boyard produces fittings for kitchen cabinets from 100 rubles. The Polish company GTV specializes in the manufacture of gas closers for kitchen cabinets, the price of which starts from 110 rubles.

For convenient operation of kitchen cabinets and drawers, closers should be installed. They are presented in several versions, which differ in the principle of operation and installation method.The closers have a simple design, which makes it possible to carry out independent installation of products when fixing kitchen cabinets. It is important to adjust the device after installation to ensure a comfortable operating environment.