Stairs to the second floor on a metal frame are becoming more and more popular with the owners of two-story cottages. Thanks to the achievements of modern technologies and the development of design solutions, such structures are able to combine various materials. In most cases, these are combinations of wood and metal. But more and more often glass and tiles coexist in the configuration of stairs on a metal frame, porcelain stoneware and stone. The possibility of combining a variety of materials in such staircase structures is endless. Ladders look creative and yet have all the qualities you need to get up and down safely.

Content [Hide]

- 1 Stairs to the second floor on a metal frame: the advantages of structures

- 2 Types of metal stairs to the second floor. Photos of models of various designs

- 3 Types of metal frame structures for stairs

- 4 Railing shapes for metal stairs. Photo examples of handrails and railings

- 5 DIY metal stair railings

- 6 Making a staircase from a profile pipe to the second floor with your own hands

Stairs to the second floor on a metal frame: the advantages of structures

The relevance of stairs to the second floor on a metal frame is explained by their high strength and the ability to combine a wide variety of materials. The structure on a metal frame is the second in the rating for use in private houses and cottages after wooden staircase systems.

Stairs made of metal and tempered glass look light and airy, but they are reliable and comfortable in operation

The main advantages of stairs on a metal frame include:

- relatively uncomplicated manufacturing process;

- the reliability and functionality of the ladder system - properly designed ladders can withstand quite heavy loads;

- strength of nodes when spliced by welding of load-bearing elements;

- the ability to use various types of metal: pipes, reinforcing steel, channels, I-beams, angles and others;

Wall-mounted metal staircase is fenced with a decorative curtain of a metal bar with shelves for decor

- the ability to combine materials and form a wide variety of stair designs;

- no squeaks during operation, durability of systems;

- the ability to make simple structures of metal stairs to the second floor with your own hands.

A variety of shapes and models convincingly demonstrates the photo of stairs on metal frames.

Self-production of a ladder on a metal frame is possible if the structure is simple and you have the skills to work with a welding machine and metal.

Right ladder calculation - a guarantee of convenient and safe operation

Types of metal stairs to the second floor. Photos of models of various designs

Stairs to the second floor made of metal (photos of various models are simply unique) can be straight and curved, spiral and elliptical. Depending on the coating, they can be glossy, matte, gilded, etc. The variety of shapes and material combinations allows them to be used in various design styles.

According to the method of application, configuration and other various parameters, they are divided into types:

- Outdoor (auxiliary) - such structures include stairs to the attic, fire escapes, stepladders, basement ladders, swimming pool ladders, and ladder systems connecting two floors from the outside of the house.

- Internal — stair structures, installed permanently inside the premises and connecting different levels of the premises. Such stairs are rightfully the central element of the room decor.

According to the manufacturing method, welded and forged stair systems are distinguished. Self-fabrication of metal stairs to the second floor in a private house using welding is a relatively easy way. The disadvantage of this method is that welding is considered a rough job, and the resulting product may not look very aesthetic. However, many craftsmen play up the welding places, giving them decorative effect.

Forged stairs are made by forging metal. Not everyone can make such stairs. But even if the structure has only forged railings for the stairs (the photo confirms this), this is enough to give it a unique elegant look.

Wrought iron railings give the stairs beauty and originality

According to the construction of metal stairs, there are solid (fixed) and prefabricated. One-piece structures are installed permanently from sections connected to each other. Collapsible ladders have a set of type-setting parts and elements. Self-assembly of such stairs is quite a feasible process.

Types of metal frame structures for stairs

According to the design of the metal frame, the stairs are classified:

- marching structures - consist of one or more marches. Depending on the location of the room, marches can be straight and turning. In turn, staircases with a turn are with a connection of flights through the platform or with the use of turning (winder, radius) steps. For self-production, a more acceptable option is a staircase with a platform. It is quite difficult to equip a metal staircase to the second floor with a turn of 90 and 180 degrees with your own hands. This will require precise design and precise calculation. However, such systems look impressive and significantly save space;

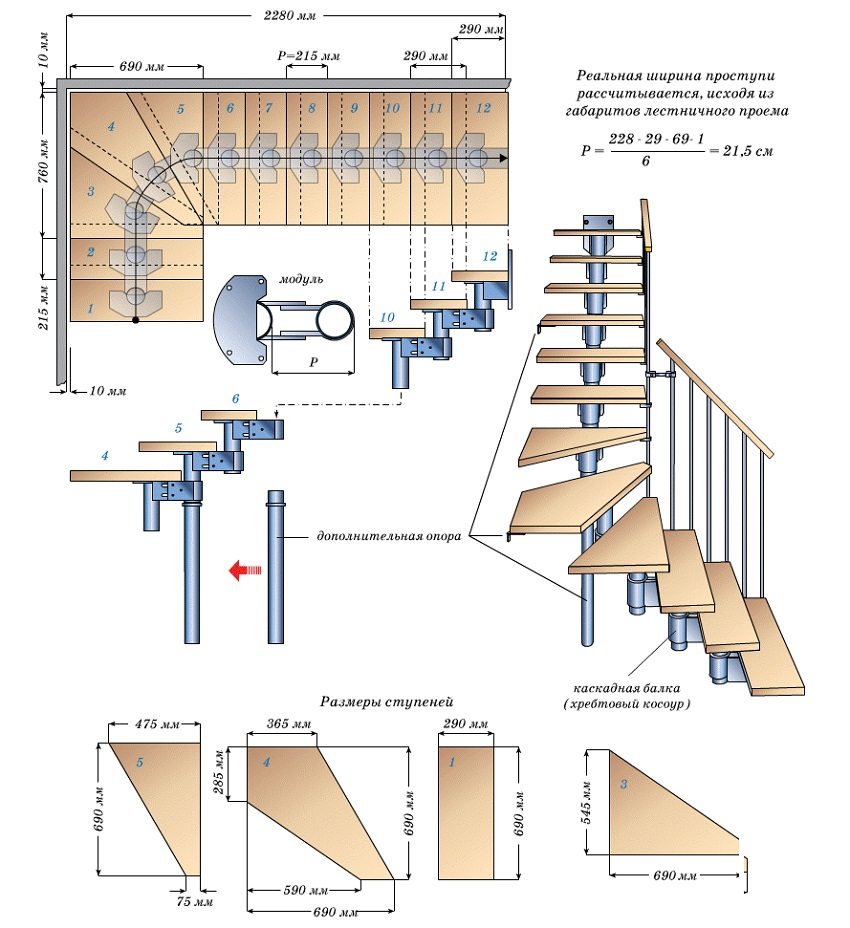

- screw (spiral) staircase systems. These stairs differ in that the steps are arranged in a circle, due to the fact that one end of the step is wider than the second. The supporting element is a pillar or column, around which the steps are mounted. Their advantage is that, with the same step length, they take up much less space in comparison with marching counterparts. Making spiral staircases from metal with your own hands (their drawings and diagrams are complex) is a rather laborious process in technical terms, requiring the necessary stock of knowledge and experience.

The supporting frame made of metal can be made in several versions:

Oblique supporting frame. With this method of arrangement, the frame is a kind of support for the steps of the stairs. This ladder system is robust and reliable. The number of support stringers depends on the stair design and the expected load.

Useful advice! If the length of the steps of the stairs is large enough, frame structures containing two oblique beams are used.

Bowstring bearing beam. In this design, the steps are inserted into special grooves in the beam and their ends are not visible from the side. Designs on bowstrings look more massive than models on kosoura.

Metal stairs on the bolts. Here the wall itself is the supporting element. The steps are attached to it with metal fasteners. Such designs look as if they are suspended in the air, they are light and graceful. There are models with support on the wall and on a stringer or bowstring.

To get acquainted with the types of structures on the Internet, there are many photos of stairs to the second floor made of metal.

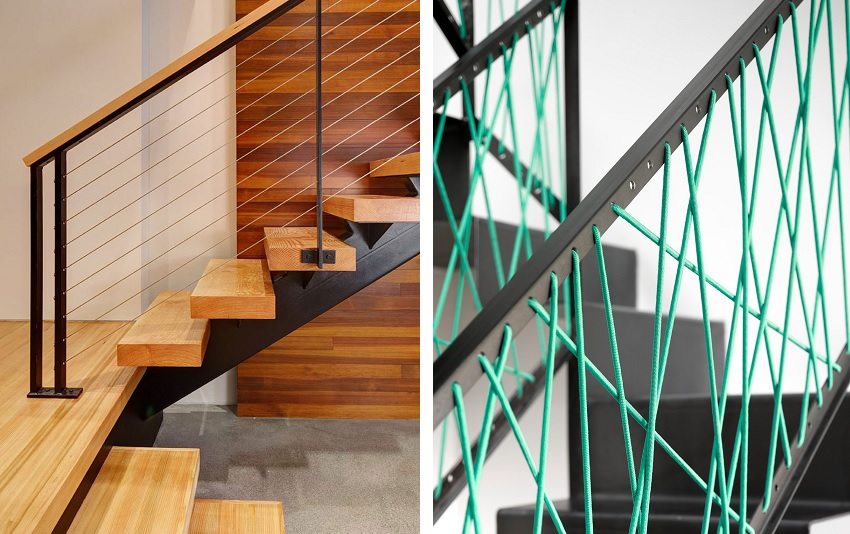

Railing shapes for metal stairs. Photo examples of handrails and railings

For the purpose of safe movement, staircase structures on a metal frame are equipped with handrails and handrails.

Useful advice! If the staircase has more than three steps, it must be completed with handrails or railings. This meets the technical requirements for the operation of stairs.

Metal handrails for stairs can be of various shapes and colors. In this sense, manufacturers offer the widest range, allowing you to choose elements for stairs in rooms of any design. In addition to the safety function, they also carry an aesthetic component, complementing the staircase ensemble.

Stainless steel handrails for stairs on a metal frame have become very popular. Stainless steel railings versatile in operation, do not require special care. They must be wiped from time to time with a napkin dipped in a special composition to give shine. At the points of sale and on the websites of manufacturers, a huge selection of accessories for stainless steel railings is offered.

Handrails and railings for stairs made of metal (photos and prices are indicated in the price lists) can be ordered in any type and shape, according to individual preferences. The price of stainless steel products will be higher than for wooden or plastic handrails, but this will more than pay off with the reliability and durability of steel handrails.

The wrought iron railing for the stairs in the house (the photo illustrates this) is distinguished by its sophistication and at the same time, it is difficult to manufacture. The process of making forged products is artistic forging. Any variations and styles of making forged railings are possible from openwork to dense and massive. The disadvantage of forged fences is their relatively high price.

DIY metal stair railings

For self-production of metal railings, ferrous metal or steel is used. The main advantages of such railings are reliability and durability. If the products are properly processed, then they turn out to be quite beautiful. To obtain a steel railing of the required shape, a metal bending method called cold is used.

For the manufacture of iron railings, two types of welding are used: semi-automatic and argon-arc. In the first variant, a lot of splashes are observed during operation. The second option eliminates this moment, and with argon-arc welding, the butt seam is smoother and more accurate, it lends itself well to cleaning and polishing. Iron welded railings are vulnerable to corrosion and require paint treatment.

Related article:

|

The available photos of the railings from the profile pipe will help you choose the option that suits you.

Making a staircase from a profile pipe to the second floor with your own hands

For the manufacture of stairs on a metal frame, profile pipes with cross-sectional dimensions of 40x60 mm are used, which will provide the structure with sufficient strength.

There are two methods for assembling the frame. You can make the entire frame outside the installation site and then transfer it directly to the place where it will be located stairs... This method may not always work, since the structure is quite heavy and you will have to resort to using special mechanisms. And the finished structure may not fit into existing openings in size.

Experts recommend making the frame directly at the installation site stairs to the second floor... In this case, mistakes made can be corrected as work is done on site.

Cutting blanks

Work begins with the choice of a staircase design: in this case, it will be a stringer structure. A staircase diagram is being developed with all the necessary dimensions and taking into account the location of the turning steps. The scheme will be needed throughout the entire time of manufacture and installation of the stairs.

Profile pipes are pre-cleaned from scale. In accordance with the scheme, work is being done to prepare the elements of the required size and quantity.

Useful advice! If you are faced with the work of making a metal frame of a staircase for the first time, try to number all the cut and finished elements so as not to make mistakes and not spoil the material.

Self-production of a ladder on a metal frame is possible if the structure is simple and you have the skills to work with a welding machine and metal

In order for the work to go faster, it is recommended that you first prepare and cut all the elements, and then start welding. But cutting down gradually as the job progresses allows fewer mistakes. It's up to you. The pipes are cut while maintaining all corners.

Installation of bearing supports

Once all the elements are cut, the supporting beams of the frame are installed. The number of beams must be equal to the number of stringers. The supporting channel is cut so that it abuts with the cut plane against the ceiling beam and the floor. In some cases, the base is prepared and the channel is welded to it.

At this stage, an important condition is the correct and parallel installation of channels (if there are several). The correctness of the entire structure will depend on their location. If a rotary system is planned, you must first make the necessary rotation of the supporting beam according to your scheme. If the diagram provides for a structure with a platform, then the ends of the supports of the flights should abut against the platform and be securely fixed.

Blanks for steps

The blanks for the steps are made in the shape of a triangle, into which the steps are subsequently laid. To fix these triangles, a point seam is used in several places. They check the correctness of the fastening and only after that they are securely fixed by welding to the main frame. Bolts are also used as fasteners.

When the first blank for the step is ready, a temporary step from the board is laid on it, then all the following "kerchiefs" are gradually mounted.

Making a frame for a 90 degree swing staircase is much more difficult. The sizes of triangular blanks will vary. Here it is recommended to prepare each element only after the previous one has been mounted.

Spiral staircase on a metal frame

Sometimes, when using a wide channel as a supporting element, instead of triangular blanks for steps, metal supports for them are welded to the base.

Metal frame processing

After installation, they begin to clean the seams. The entire metal surface of the frame is processed: degreasing, applying anti-rust compounds, primer. Further, the metal is covered with paint. If a stainless steel profile was used, no processing is necessary.

Stair treads can be made of wood or metal. A more exotic option is stone or glass. If a tree acts as steps, the shelves of the triangular corners should be at the bottom, if stone or concrete, the shelves are directed upwards.

The main advantage of ladders on a metal frame is the ability to combine different materials in a wide variety of combinations. At the same time, staircases on a metal frame are strong, durable and can match any interior style.