Eco-veneer interior doors are made of an economically beneficial material with a synthetic coating, which looks very similar to a cut of natural wood - veneer. Before buying, many are interested in what such products are, what are the pros and cons they have. Clients also want to learn more about the types, sizes, color palette of the canvas. The information in the article will help you choose a product, learn about the properties of the material and options for caring for it.

Content [Hide]

- 1 Interior doors eco-veneer: what is it

- 2 Doors eco-veneer from the manufacturer: manufacturing features

- 3 Veneered doors: what is it

- 4 Eco-veneer doors: pros and cons

- 5 Eco-veneer doors: reviews, types and selection

- 6 Interior doors eco-veneer: reviews and sizes

- 7 Interior door color solutions: options

- 8 Interior doors eco-veneer: how to install correctly

- 9 Eco-veneer doors: price and care of the canvas

Interior doors eco-veneer: what is it

The name "eco" corresponds to the way the product is made. The composition includes adhesives and wood fiber. The sawdust is pre-painted, thoroughly mixed and glued together. Eco-veneer doors from the manufacturer will cost less than buying them through intermediaries.

In terms of performance, this material is not inferior to natural wood. The door leaf covered with eco-veneer is resistant to the following factors:

- humidity;

- temperature drops;

- light blows;

- scratches.

The consumer will also not be left indifferent by the glossy material, which gives the product a special appeal.

Doors eco-veneer from the manufacturer: manufacturing features

Production is carried out using special presses. The basis includes waste resulting from wood processing: shavings and sawdust. The latter, thanks to the latest technology, are mixed with synthetic resins.

The step-by-step type of pressing leads to high reliability and material stability. Wood fibers are impregnated with special dyes. As a result, sheet material is obtained, it is released in rolls. Sheets are cut and applied to all details of future doors (MDF and drawers).

Only after wrapping each outer part of the canvas with an eco-veneer do all the details come together.The listed production technology eliminates the likelihood of material flaking, increases its operational life, and ensures the safety of the external data of the product.

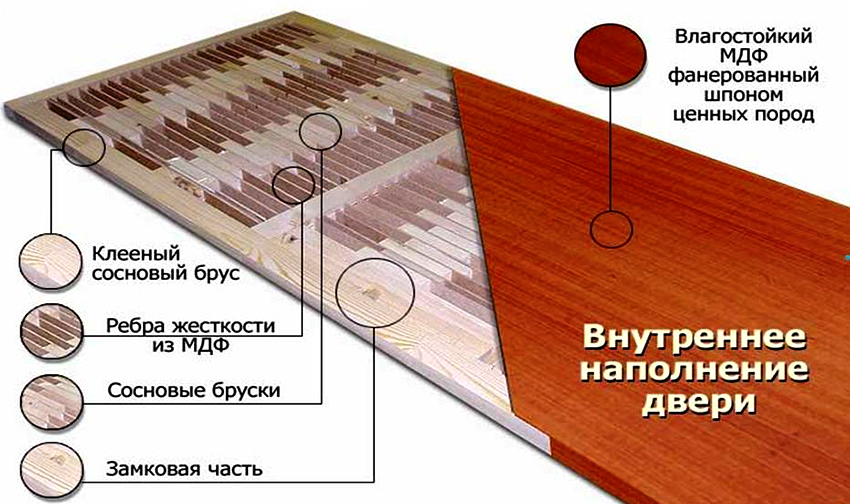

The constructions are classified under the CPL brand, which indicates the multi-layered fabrics. Doors of white eco-veneer (or any other color) consist of the following parts:

- frame made of laminated veneer lumber, which includes natural coniferous wood;

- built-in elements, lintels - upright for doors (drawers);

- MDF boards, responsible for the formation of the surface of the door leaf.

Fastening of eco-veneer is carried out on wood sheets.

What equipment are used for making doors from white eco-veneer

Why is white material preferred? This is a classic color that suits almost any interior design. The high-quality assembly of an interior door of an eco-veneer from the manufacturer is facilitated by the availability of specialized equipment:

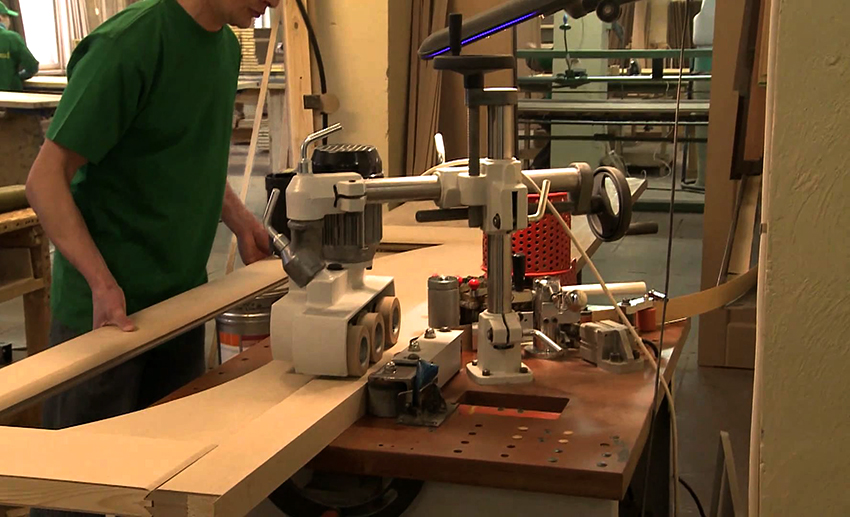

- The milling machine helps to make the main part of the product. At this stage, connecting elements are formed: spikes, grooves.

- A special press glues the door frame. The device is also indispensable for attaching overhead components of the canvas.

- The circular saw allows you to lay out the format and cut the bar.

- Small operations and finishing require carpentry tools: jigsaws, grinders, clamps, staplers.

Important! In terms of durability, eco-veneer is not inferior to natural wood mass.

Veneered doors: what is it

The interior veneer blocks are covered with a thin layer of wood that has retained its structure. Manufacturers offer several types of veneered sheets:

- Natural - aesthetic appearance is relevant for cladding.

- Reconstructed - contains tropical wood. Suitable for finishing furniture and other interior elements.

- Rib glued - represents thin sheets of wood connected along the edges.

Interior doors made of natural veneer are obtained by the method:

- planing - valuable types of wood are used, in thickness not exceeding 0.5 cm;

- peeling - shavings are formed in a spiral up to 1 cm layer in thickness;

- cut - "sawn lamella" involves sawing logs to the formation of 1 cm of fibers. The most expensive production option. Applicable exclusively for exclusive interior elements.

A veneer door has the following advantages:

- durability;

- strength;

- a wide range of design solutions;

- absolute similarity with natural solid wood at a reasonable price;

- light weight, excellent sound and heat insulation, easy installation;

- environmental friendliness of the material.

The disadvantages of veneer include the lack of identity of the same fiber. Its cost exceeds the price of eco-veneer. Comparing the characteristics of both materials, everyone decides for himself which is better: eco-veneer or veneer.

Inexpensive doors: eco-veneer or veneer

Eco-veneer interior doors suggest the presence of artificial material that imitates real wood. Veneer is a thin layer of natural wood cut. Natural shades of natural material lend comfort to the interior.

From a practical point of view, the prefix "eco" indicates that the product is not inferior to natural material in many characteristics. Eco-veneer is not subject to the destructive effects of an aggressive environment. The surface is resistant to acids, mechanical stress, any detergents.However, technologically advanced multilayer plastic does not look as elegant up close as a simple veneer made of natural material.

Interior veneer sheets will be more expensive than a sheet with an "eco" prefix, but both options are classified as inexpensive doors. Regardless of the buyer's choice, the availability of the material makes these interior elements very popular.

PVC doors: what is it

Interior door blocks made of polyvinyl chloride are finished with a special film. The frame contains bars made of coniferous wood. Before production, the latter are thoroughly checked for the presence of knots and other defects. As a filler for most models, the most affordable option is used - honeycomb cardboard, although MDF or chipboard can be used.

One of the important elements of the canvases is considered to be a polyvinyl chloride film. Outwardly, it perfectly repeats the texture and pattern of natural wood. Before deciding which is better: eco-veneer or PVC - it is important to clarify the advantages of polyvinyl chloride:

- weighs less than natural solid wood;

- polymer film is responsible for the durability of the canvas;

- ease of installation;

- keeps external and technical data for a long time;

- large selection of color palette;

- in the event of a breakdown, any element of the block is easily selected;

- interior linens are not afraid of moisture, household chemicals and mechanical damage.

Important! New production technologies and polymer film are responsible for the durability of the canvas.

PVC doors or eco-veneer: which is better

PVC doors are painted, laminated and covered with special enamel. Polyvinyl chloride contains a safe (within normal range) chloride component. Therefore, the material is considered environmentally friendly. Unlike eco-veneer, the film is applied to the sheet using pressing. The average service life of the product is 7 years.

Related article:

White doors in the interior: interesting ideas and unusual design solutions

Interior and entrance types of products, advantages and disadvantages. Decorative qualities of door designs.

The main disadvantages of PVC include the impossibility of restoring the coating even with the slightest damage. Has a less presentable look and sound insulation compared to eco-veneer.

Eco-veneer doors: pros and cons

Having found out what interior eco-veneer doors are, it's time to clarify all the advantages of the material:

- The price is 2-3 times lower than the cost of a door block made of natural wood by almost 5 times - sheets of 100% solid wood.

- High abrasion resistance - the synthetic coating is scratch resistant, which is suitable for large families with small children and pets.

- The material is not afraid of temperature drops, room humidity. Relevant for the kitchen or bathroom.

- Excellent imitation of natural wood.

- It is lighter in weight than wooden sheets, even if there is a filler inside a full-fledged pine array.

- Maximum safety. There are no chloride, formaldehyde and other impurities harmful to humans.

- Easy to care for. It is enough to wipe the eco-veneer with a slightly damp cloth. The use of cleaning products is optional.

- The average service life is 10 years, which is 3 years longer than PVC.

Before you buy eco-veneer doors, it is important to familiarize yourself with the drawbacks of the material:

- Insufficient sound insulation, especially when compared to 100% solid wood.

- Deformation of the canvas with frequent strikes of the door block against the wall. The reason lies in the low weight of the eco-veneer door.

- The inability to restore with severe damage to the canvas. In this case, the door will need to be replaced.

- Synthetic material does not allow the canvas to "breathe", which is a little, but still negatively affects the indoor climate.

Euroshpon: what is it, properties and types of door leaf

Euroshpon is referred to as a revolutionary modified material. This is a worthy analogue to expensive canvases: natural veneer, 100% solid wood. The unique production technologies make the doors look complete. The material does not require pretreatment, cutting, grinding and priming.

The multilayer structure is responsible for the increased elasticity of the coating. The main advantages of this material are:

- increased endurance in relation to moisture;

- resistance to chips, impacts, abrasion and other mechanical damage;

- UV resistance;

- hypoallergenic and ecological cleanliness of paintings.

The innovative three-layer Euro veneer covering completely recreates the texture of natural solid wood fibers. Manufacturers offer the buyer a choice of different options for opening mechanisms: swing or sliding.

Important! Environmental friendliness of the material allows you to install doors even in a children's room.

Eco-veneer doors: reviews, types and selection

Those who already use an eco-veneer door, for the most part, leave positive reviews about the product. The door leaf is deaf, with glass and tsarovy. The first option does not contain inserts (only vertical and horizontal elements imitating a tree are possible).

Facing the sheet is carried out by processing each element, each part of the set from all sides. The product is assembled using dowels, with further gluing of each seam. A special assembly technology is designed to maintain the geometry of the canvas for a long time.

Before you buy interior doors eco-veneer, it is important to consider the following points:

- You should take a closer look at the convenience and reliability of the design. The functionality of locks and latches is checked by opening and closing.

- It is important to make sure of a sufficient level of fire safety and environmental friendliness of the material. Such information is indicated in the technical data sheet for the door unit. Installation of specimens with glass inserts is not recommended in the children's room.

- What is eco-veneer? First of all, these are various configurations and color schemes. They must match the interior.

- Possible additional tint layer tells the buyer about a low level of surface quality.

- A thorough check of the integrity of the canvas is another aspect of choosing the right piece.

- The door must be checked to ensure that the coating meets the requirements for it. Otherwise, you may not notice the presence of defects. There is a chance to get, for example, laminate instead of eco-veneer.

- A high-quality model has a pleasant to the touch, smooth surface.

- The shape of the door must be rectangular. When entering the box, the web should be 1 mm between the ends. All angles are certainly kept in strict perpendicularity.

- When closing, no gaps or overlaps should appear.

- When consulting with a company manager, do not forget about your requirements and desires regarding door decoration.

- Pricing depends not only on the quality and design options of the material, but also on the type of delivery and door installation: self-pickup or delivery, self-installation or factory installation.

Eco-veneer interior doors: requirements for a bathroom

When purchasing a product for a toilet and a bathroom, the buyer has special requirements for the door leaf. The specifics of the premises involves taking into account the following aspects during installation:

- the presence of condensate, water vapor on the interior block;

- negative impact on the canvas of temperature changes;

- high permeability of premises.

Eco-veneer doors are perfect for a bathroom, since the material is resistant to sudden changes in temperature

The quality of eco-veneer doors, reviews of them indicate that the canvas can be:

- resistant to sudden changes in temperature conditions;

- moisture resistant;

- easy to care for;

- with the presence of high-quality fittings, which allows you to count on the durability of the handles and hinges.

It remains to determine which interior doors are best. The choice of color, type and quality of material remains with the buyer. The manufacturer is responsible for the resistance of the canvas to the negative influence of moisture.

Eco-veneer doors: a catalog of blank canvases

The blind door does not have glass inserts. For connoisseurs of transparent structures, manufacturers offer sheets with separate glass fragments, independent compositions, or completely glass. The latter are matte or transparent.

Deaf specimens do not require special care. They serve as a good protection of rooms from noise. Fits perfectly into any interior solution.

Interior doors eco-veneer: properties of side panels

Collar door leaves have at least three transverse strips. The rigidity of the frame (from the side racks and strips) is supplemented by any auxiliary materials. The assembly process for each piece is similar to the principle of the production of paneled canvases.

In case of mechanical damage, it is possible to replace certain modules. Tsargovye doors are a design that gives the canvases additional possibilities in terms of decor and impeccable practicality in operation. During assembly, each part is individually attached to the cladding. This type of door block is easy to repair.

Interior doors eco-veneer: reviews and sizes

According to reviews, eco-veneer is not only aesthetically attractive, but in most cases is suitable for buyers in size. The standard height of the models reaches 200 cm or 2000 mm, and the width ranges from 600 to 900 mm. The thickness of the canvas reaches 40 cm. Depending on the manufacturer, the latter indicator differs by 1, maximum 5 mm. This is also referred to as the generally accepted norm.

Non-standard dimensions are considered to be a height from 2100 to 2300 mm and a width of 400 or 1000 mm. These models are more expensive than standard ones, by a maximum of 30%. Due to their light weight, door blocks that are too wide or too tall are rarely seen. For a long service life, instead of an "empty" frame, you should give preference to the model with solid pine.

Important! Spliced or one-piece solid pine allows for better heat retention, protection from noise. These specimens are more expensive than similar ones in the series, but cheaper than natural solid wood.

Interior door color solutions: options

Eco-veneer or veneer: which is better? Each buyer decides this issue independently. Having decided on the option, proceeds to the choice of color. The coating imitates natural wood as accurately as possible. The canvases take the following types of wood shades:

- beech;

- wenge eco-veneer doors;

- larch;

- light oak;

- ash;

- Italian walnut;

- mahogany.

Non-standard color solutions are:

- smoky gray;

- pearl vanilla;

- white;

- cappuccino;

- other unusual tones.

You can buy an eco-veneer film of any color at a reasonable price. A wide range of shades helps create a unique image of the room. Depending on the selected shade, the room takes on a modern or classic look.

Interior doors eco-veneer: how to install correctly

By purchasing interior doors, usually the company offers its installation services. What if the client decides to handle this process himself? In this case, the installation instructions below come to the rescue:

- Upon receipt of the ordered door unit, it is important to carefully check that each element is available, so that the dimensions of the leaf correspond to the declared ones.

- It is necessary to apply important marks with masking tape and a simple pencil. To open the doors to the right, just bring a piece of tape to the top right corner. If the doors have a glass insert, the side of the glossy surface should be marked. Do not forget that on the other hand the glass is matte.

- Lay the foam or cardboard mat with the marks upwards.

- Mark the location of all loops. The notch is made 20 cm from the edge of the web. To carry out the procedure, use a knife and a building corner. The loops themselves are measured. The length and width markings are applied to the door leaf.

- Using a milling cutter with a diameter of 14 mm, cut holes for the hinges. First, the apparatus is adjusted directly to the width of the loop. Next, the central and extreme part of the material layer is cut out precisely for the hinges. In places where the router was powerless (did not remove the layer), using a chisel is suitable. The latter will help to cut the appropriate openings for the hinges.

- It is necessary to carefully prepare the holes for the self-tapping screws responsible for fixing the hinges. For greater reliability, dowels should be used.

- After cutting the upright elements, 4 right and left contractions should come out. The angle of the cut itself is 45º.

- They mark the location of certain loops on the mullion parts. For example, the left part of the hinges is suitably applied to the same side. After leaving a gap of 3 mm, the required markings are transferred from one structure to another in stages. A corner is placed on the edge of the hinge, measured to the edge of the door, a similar segment is broken off with the addition of one millimeter per box.

- Drilling and cutting of supporting elements for existing hinges is carried out.

- The gap at the bottom between the doors and the floor should be 1 cm. The excess is cut off with a miter saw.

- The mullion elements are cut in half (at an angle of 45º), they are laid on top of the canvas.

- To assemble the entire structure and fix the hinges, self-tapping screws and a drill are required.

- The door frame is being installed in pre-drilled holes.

- The wedging is carried out with wooden wedges. Adjust the box.

- Fix the block with the hinges already inserted.

- Having made several potholders, they start foaming the canvas.

- The door handles are mounted at a distance of 1 m from the bottom edge of the door module.

- Fastening to finishing nails with a small head.

Important! If the interior doors of the eco-veneer are correctly installed (have no gaps), they will not let heat and noise through, even with cardboard filler inside.

Eco-veneer doors: price and care of the canvas

It is noted above how eco-veneer differs from veneer. The cost of the product is also available for most buyers. On average, the price range of eco-veneer door leaves ranges from 1000 to 12000 rubles. Premium doors can be significantly more expensive.

It is enough to wipe the doors made of eco-veneer with a solution of water and alcohol in a ratio of 9: 1

But how to take care of the material? A solution of water and alcohol in a 9: 1 ratio is ideal for cleaning doors. The only condition is a soft cloth without the presence of abrasive hard elements. After cleaning, the surface is wiped dry.Door modules with an artificial finish do not require the use of special resins, wax or other coating protection agents.

In the photo, the eco-veneer doors practically do not differ from one hundred percent solid wood. Having determined in advance which doors are better (PVC or eco-veneer, veneer or eco-veneer), the difference between them, buyers come to the conclusion that the option they have chosen has a number of advantages. This is an excellent solution for those who are on a budget, but want their doors to look like natural solid wood.